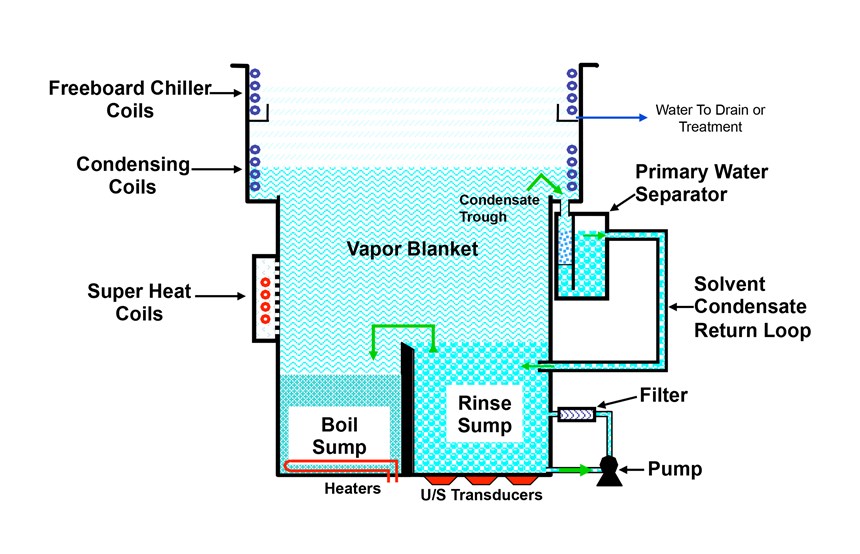

Vapor degreasing uses solvent immersion combined with vapor rinsing and drying to remove all types of oil, grease, wax, flux and particulate. It is a closed-loop system consisting of a top-loading steel vessel composed of two chambers, both filled with solvent. In one chamber, the solvent is heated to a boil, and this then generates a vapor cloud that rises to meet two sets of cooling coils. These cooling coils cause the vapors to condense and return to their liquid state. This liquid is then channeled to the second chamber, the rinse chamber.

A hoist lowers a basket containing the contaminated parts through the vapors and into the boil sump first. The basket is then lowered into the rinse sump containing the clean solvent that has been condensed from the vapors. This process is easily programmable and allows for excellent process control and repeatability. The parts come out clean, dry and ready for packaging or further processing.

In the past decade or so, companies have commercialized environmentally acceptable cleaning chemicals suitable for vapor degreasing. This means that the speed, convenience and energy savings of this technology now is easily available to engineers everywhere.

The following describes the three types of vapor degreasing options and their chemistries. Note that each has its advantages as well as its drawbacks, but they all can be beneficial if used in the right application.

Mono-Solvent Degreasing

This type of vapor degreasing, as its name suggests, contains only one component and is usually the most cost-effective option because it is easier to manufacture.The operator also does not need to monitor solvent concentrations or worry about what solution to add into the one-component degreaser. And because the composition remains consistent, it can clean in both liquid and vapor phases, making it a practical option.

However, the mono-solvent’s cleaning abilities are limited, and some of the most common mono-solvents today can have flammability or toxicity issues. N-propyl bromide (nPB), trichloroethylene (TCE) and perchloroethylene (PERC) are some of the most popular mono-solvents, and they can all contribute to safety and environmental problems.

Although mono-solvents can be relatively aggressive in cleaning strength, they are best used to remove machining oils and lubricants consisting of hydrocarbon components. High-boiling mono-solvents can be used to melt waxes and remove high-boiling contaminants. They also work well on metals, although it is important to monitor the process for acid acceptance if using one of the less stable (chlorinated) mono-solvents.

Azeotrope Degreasing

An azeotrope is a blend of two or more components which, when mixed together, behave as if they were one chemical, delivering the benefits of a mixture of different elements with the convenient handling and storage of a single compound. It is a stable mixture that remains together in the liquid and vapor phases, so the structure stays the same throughout the vapor degreasing process.

For example, flammable and non-flammable ingredients can be combined to produce a stable, non-flammable mixture, an important safety benefit. This makes cleaning simpler, safer and more reliable.

Azeotropes use filters and membranes to distill rather than trap contamination. They then can be repurified while the contamination is “locked” into the liquid at the bottom of the vapor degreasing machine.

Azeotropes can be modified to obtain physical properties, making the blends useful across a range of applications and on a variety or combination of organic, inorganic and particulate contaminants. This means they work well on most substrates and fluorinated azeotropes, with the added benefit of not requiring acid monitoring.

Because they can be tailored to the contamination, azeotropic mixes can clean much faster than some mono-solvents, reducing the cleaning cycle time by as much as 75 percent and increasing productivity.

With many regulatory organizations such as the U.S. Environmental Protection Agency considering measures to reduce and restrict the uses of substances containing nPB, PERC and TCE, like mono-solvents, because of safety concerns, azeotropic cleaners are becoming known as a viable replacement. Because they can be blended, chemicals such as nPB can be eliminated, giving them much better toxicity profiles.

Although azeotropes cost more per pound than mono-solvents, they are still competitive, and the fact that they are comprised of safer, more stable chemistries outweighs any cost implications. Additionally, training and process optimization can make cleaning with azeotropes more efficient and cost-effective than mono-solvent cleaning.

Co-Solvent/Bi-Solvent Degreasing

Co-solvents/bi-solvents are the most complex, but also the most powerful cleaner available for a vapor degreaser. These systems use a non-volatile cleaner in combination with a volatile rinsing solution. Most of the cleaning is done in the non-volatile cleaner, which is then rinsed off by the volatile fluid. The benefit of these systems is that the non-volatile cleaner can be adjusted and modified to fit the specific cleaning requirements. Occasionally, a contamination cannot be managed by a mono-solvent or azeotrope because of material compatibility issues, throughput problems or environmental regulations.

A co-solvent may provide the required cleaning power without the use of ingredients under regulatory restriction or solvent-sensitivity issues. It can be formulated to be non-chlorinated or free of volatile organic compounds, for example.

There are a few downsides to co-solvent cleaning, however, the most obvious being the requirement for a separate cleaning tank. This solvent cannot be used in a one-sump vapor degreaser or with vapor-only cleaning, and the extra cleaning cycle results in a reduction in throughput.

Another disadvantage to this chemistry is that it requires monitoring to ensure the concentrations of each component are correct. This necessitates extra training to guarantee that the correct additions are made to the system when necessary.

What a co-solvent system can give the user in return is the ability to remove difficult soils, which often requires high temperatures. It delivers almost the same convenience and speed as traditional solvent cleaning, but increases this cleaning with a second chemical, providing the additional cleaning “horsepower” that the application may require.

Making an Educated Choice

Once shop management has determined which vapor degreasing method may be the right fit for an application, it is essential that the method first be tested. Experience and expertise are helpful in optimizing and developing cleaning cycles that will best suit a specific job, so it also is important to consult with a vendor who can test and provide cleaning solutions to meet requirements.

About the Author

Venesia Hurtubise is a critical cleaning lab technical service chemist with MicroCare Corp.

Read Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)