Cloud Computing in Manufacturing

Cloud computing has potential to be game-changing technology in manufacturing for everyone from small shops to extremely large manufacturing plants.

In 1984, John Gage and Bill Joy of Sun Microsystems were traveling on a train in China discussing how the world of computing was changing. This conversation sparked Mr. Gage to make the comment, “The Network is the Computer.” This became the title of his talk in China and became the tag line for Sun Microsystems. Back in the mid 1980s, this phrase was misunderstood by anyone outside the world of computing. Today, it’s the purest definition of cloud computing. Unless you have been in the computer industry for a couple of decades, chances are that cloud computing is difficult to comprehend and very misunderstood.

What is cloud computing and why is it so misunderstood? Cloud computing is a broad, umbrella term for many types of computing. If you ask 10 people what the term cloud computing means, you’re likely to get 11 different answers. Flickr, Gmail, Google, LinkedIn, Facebook, QuickBooks, SalesForce.com, Carbonite and Farmville are just some examples of applications that run in the cloud.

Cloud computing has potential to be game-changing technology in manufacturing for everyone from small shops to extremely large manufacturing plants. The key is understanding the process, ask-ing the right questions and making wise provider decisions.

This year the International Manufacturing Technology Show (IMTS) 2010 Emerging Technology Center featured a cloud computing area that was a big hit. A typical conversation about cloud computing, in order to explain the term, went like this:

When you Google something, do you know specifically what city the servers are located in when your search query is actually being run? For that matter, do you care?

The answers were usually something like, “I don’t know and I don’t care. I simply want my results to come back to me quickly.”

Then cloud computing experts asked, “Would you rather have a small nuclear power plant in your backyard that you owned and managed, or would you rather just pay for what you use from the electric company?”

The answers were, as expected, “I just want to pay for the electricity that I use and not worry about it.”

That is exactly what cloud computing is all about at a high level. From a technical standpoint, a large server farms are used that someone else runs and maintains (loading new software, upgrades, patches, virus protection, and so on), the user pays for exactly what is used and in return, they get their requested results.

Cloud computing is important for manufacturing because it allows companies to avoid the countless lists of business and technical issues associated with running their own data centers and save money by only paying for the computing resources when they need it on a “pay-as-you-go” model.

To truly understand and appreciate the benefits of cloud computing, it is important to first understand the key building blocks—fast bandwidth, the Web browser and large server farms.

Fast bandwidth: Instead of moving the data equivalent to a paragraph per second during the dark days of dial-up, you can now move a book per second with broadband. With these huge communication pipes, the planet just got a whole lot smaller.

Web browser: Sometimes it’s easy to forget how ubiquitous the browser is for software applications for both home and office.

Large server farms: There are hundreds of thousands of computers that are heavily used during a couple months each year, but then just twiddle their processor bits the rest of the year. Amazon is the classic example. The company is very busy during November and December, selling books and goods, but the rest of the year, the systems are lightly used. Someone at Amazon came up with the brilliant idea of selling time on those systems

to offset the huge costs of running hundreds of thousands of computers.

With these three technical pillars of cloud computing in place, it allows software companies to offer their software on these large server farms as a “service.” In other words, users simply point their browser at the software in the cloud and off they go. Users pay for what they use, when they use it.

Why are software companies rapidly moving more and more of their applications to cloud computing? Because users are demanding it and are tired of running their own “nuclear power plants.” They are tired of buying lots of servers and then learning that these servers are only being used on an industry average of 8 to 15 percent of the time. Users are tired of all the patching, upgrading, malware, viruses and the plethora of issues that come along with running their own data center. This is especially important for a small manufacturing shop, where there’s no time to constantly worry about all of the patches, upgrades and system administration work.

SalesForce.com is one of the best and a classic example of cloud computing. Many credit SalesForce.com with starting cloud computing by offering Customer Relationship Management (CRM) as a Software as a Service (SaaS). SaaS is one of the categories of cloud computing that most manufacturing companies are interested in using. SaaS took SalesForce from a long and detailed list of what servers a customer needs to support a large CRM system on-site, to a simple and straightforward, “All you need is a browser and you have a CRM system.”

SalesForce.com takes care of the rest. This is only one example of the dramatic differences between cloud computing and the standard method.

In addition to SaaS, there are two other categories of cloud computing: PaaS or Platform as a Service and IaaS or Infrastructure as a Service.

The most important part of cloud computing is the elasticity of the cloud for businesses. Elasticity means the ability to scale up (add computers dynamically) and scale down according to business needs. SalesForce.com worries about having all the processing power and storage available for their customers. The beauty of cloud computing from a customer’s viewpoint is as you need more or less computing power or storage, it is simply turned on or off in the cloud.

Scalability applies to large, global manufacturing companies as well. Let’s say a company is using software in the cloud for one of its manufacturing plants and the president says, “This is working out well—let’s use this for all of our plants worldwide.” At this point, the company informs the cloud computing software company of this new need and the number of computers in the cloud will be made available as the new plants start using the software. In contrast, the traditional model would call for months of sizing exercises to determine how many new servers would be needed for each plant, purchasing and then configuring the software at each of these plants. With cloud technology, months are reduced to minutes to enable the other plants.

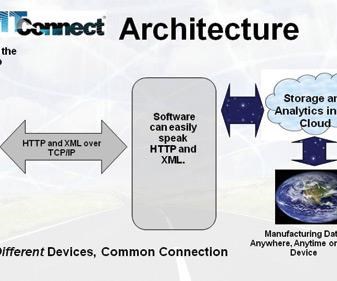

MTConnect is an example of the importance of cloud computing in manufacturing today. MTConnect is an open and royalty-free protocol standard that allows manufacturing equipment to have a common language to exchange information. As machine tools start spitting out gigabytes of information per hour, it doesn’t make sense to store all this information locally. Even for a large manufacturing plant, no one wants to invest in a lot of servers that will be antiques in less than 4 years. However, it makes the most sense to securely store this information in the cloud and use as many (or as few) processors to analyze this data as needed and pay only for what is used.

There are important checklist items to verify when selecting a company that has a cloud version of its software or a cloud provider that will be the development platform. At the top of this list is proper security. The University of California, Berkeley, white paper, “Above the Clouds: A Berkeley View of Cloud Computing,” written by U.C. Berkeley’s Reliable Adaptive Distributed Systems Laboratory, offers a lot of valuable information for considering cloud computing. Topics include data confidentiality and audit-ability; data lock-in; data transfer bottlenecks; availability of service; and performance unpredictability.

The first two topics deal with security. The level of security is totally dependent on the level of security the cloud provider has in place. Security is an end-to-end problem. Whether dealing with a small manufacturing shop or a large global manufacturer, it is critical to ask clarifying questions to understand the security that is being provided. The first two questions to ask a cloud computing vendor are: Is my data secure at rest? Is my data secure in flight? You are asking whether your data is encrypted on their storage devices or as it is being moved from one point to another. If the answer is anything but an unequivocal yes, then raise the red flag. Start with these questions, but they are certainly not the only security questions.

Now it is important to understand if your cloud provider is a roach motel in terms of data storage. How easy is it to get data out of the cloud? This answer becomes important if the cloud computing company were to go out of business and take the user’s data with it.

After addressing security concerns, the next issue is the availability and performance of the cloud computing provider. The Service Level Agreement (SLA) is important to have in writing. The SLA is the percentage of uptime the cloud provider guarantees. If the cloud provider does not state a number in a contract, make sure to receive a credit for the time the provider was down. SLAs do not guarantee recouping the loss of business revenue for downtime. So, it’s critical to understand the specifics of an SLA and have a contingency plan in place for times the service is down.

PaaS or Platform as a Service and IaaS or Infrastructure as a Service are two other considerations for manufacturers. PaaS and IaaS are for companies that are developing their own software. PaaS provides components that allow developers to combine these components or “mash up” to create new applications. IaaS provides the ability to create virtual machine images (VMI) and run these VMIs in the cloud. All software companies should investigate SaaS, PaaS and IaaS.

Here are three things to ask software vendors about cloud computing and specifically SaaS:

Do they have a cloud version of your software? If they do, you need to understand all the pricing options. Also, understand the ability to migrate from a cloud version to a standard software version in the future, if you choose to do this down the road.

Security, security, security. You must understand all the issues here.

Performance and availability. Get it in writing and understand the issues.

Cloud computing should be investigated, whether you are a small manufacturing shop or a large global manufacturer. If you are a software company in manufacturing, then you don’t have a minute to waste before investigating cloud computing because your customers will be demanding it, and it is the logical next step in a product road map. But, as with any technology, it is important to separate the quality cloud providers from the disreputable cloud providers.

— AMT - The Association For Manufacturing Technology

Related Content

ProShop Provides ERP Technology to Purdue Engineering School

The ProShop Digital Ecosystem will be used as the inventory management and ERP system at Purdue University’s Industrial Engineering School.

Read MoreAvoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MorePMTS 2023 Product Preview: Shop Management Software

Learn about some of the latest shop management software solutions that will be on display at PMTS 2023.

Read More10 Ways AI Might Impact Manufacturers

Artificial intelligence offers the promise of assisting decision-making processes and boost overall manufacturing efficiency.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More