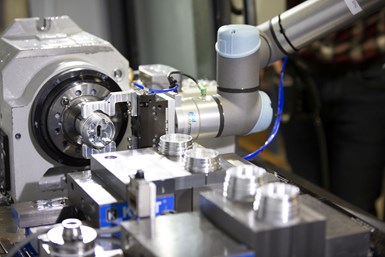

Toolcraft Inc. uses a pneumatic gripper to tend its machine, deliver parts to rinsing and drying stations, then place cleaned parts on a rack for shipping. (Photo Credits: Universal Robots)

Grippers are devices that enable robots to pick up and hold objects. When combined with a collaborative robot (“cobot”) arm, grippers enable manufacturers to automate key processes, such as machine tending, inspection, assembly, and pick and place.

It is useful to think of grippers as similar to the human hand; they are positioned at the end of the cobot arm, thus combining an arm’s strength with a hand’s dexterity. This combination opens up a range of possibilities for material handling with cobots.

There are many different types of grippers available to use with Universal Robots’ cobots. Some gripper designs are just like human hands, complete with five fingers. There are other grippers with two and three fingers, grippers shaped like claws, mechanical gripper types, grippers with large suction cups and even grippers that look like air-filled bags. With so many to choose from, it can be difficult to know which robot gripper types are best suited to which applications.

For general purposes, though, grippers can be divided into four main types, each distinguished by the methods used to power and/or control the gripper itself. These include:

Pneumatic grippers. This gripper uses compressed air and pistons to operate its “jaws” or “fingers.” Most commonly found in two- and three-finger configurations, pneumatic grippers are versatile tools that can be used in a wide range of applications.

For example, Toolcraft Inc., a machine shop in Monroe, Washington, chose the PHD PneuConnect pneumatic gripper to automate a tricky machine-tending task for a part that required three operations. Combined with a UR5e cobot (which provides repeatability down to 30 microns), the system was able to place parts in the machine and, when the machine had finished its work, grip and dip the finished part into a rinsing solution, pass it through an air jet, and then place the washed and dried part on a rack for shipping.

Pros of pneumatic grippers include low cost, large grip force range, the ability to operate in tight spaces and fast response times. However, pneumatic grippers are best suited to handling single part types, so they might not be a great fit for a high-mix/low-volume production environment. This gripper type also provides limited force and position control, and requires compressed air to function.

Hydraulic grippers. Powered by hydraulic fluids, hydraulic grippers provide more gripping power than their pneumatic counterparts, making them well suited for heavy duty applications. However, with that power comes some disadvantages, including the added complexity of a pump, reservoir and oil handling. Consequently, hydraulic grippers tend to require more maintenance than other gripper types.

Electric grippers such as this two-finger unit used at Stamit in the Czech Republic are well suited for applications that require high speed and light to moderate gripping force.

Electric grippers. These grippers are a popular choice for many cobot applications including machine tending. While they don’t offer the same level of gripping power as hydraulic grippers, they are suitable for applications that require high speed and light/moderate gripping force. Electric grippers usually come in two-jaw and three-jaw configurations, with three-jaw grippers often being chosen when cylindrical objects need to be handled.

For example, Stamit, a machine tooling company based in the Czech Republic, uses a two-finger electric gripper from Robotiq and a UR10 cobot to take care of CNC machine tending tasks in its high-mix production environment that creates 4,000 different parts and 12 million total parts each year.

The defining feature of electric grippers for manufacturing automation is control. Most electric grippers come with microprocessors that enable users to vary gripping force and speed. The addition of a force sensor enables electric grippers to easily handle different part types. Conversely, while electric gripper designs continue to get more powerful, they commonly provide less gripping force than pneumatic grippers and tend to be more expensive.

While vacuum grippers typically wouldn’t be used for machine tending, shops could find them useful for packaging.

Vacuum grippers. While a machine shop likely wouldn’t use vacuum grippers for machine tending, they could be used for manipulating cardboard in a packaging cell.

These grippers use the difference between atmospheric pressure and a vacuum to lift, hold and move objects. Typically, the vacuum (or “vacuum flow”) is generated by a miniature electromechanical pump or a compressed air-driven pump. The vacuum flow must be uninterrupted to ensure that the cobot can safely hold the object it has picked up.

Compressed air-type grippers produce between four and 10 times more power than their electromechanical counterparts, which makes them a good fit for lifting heavy weights. However, electromechanical-driven vacuum grippers shine in applications requiring a high degree of mobility.

Advantages of vacuum grippers include the ability to handle many different types of items (even when those items are imperfectly positioned) and a lower price compared to other types of grippers. Disadvantages include added electricity costs to power compressed air or vacuum pumps and sensitivity to dusty conditions.

Choosing a Gripper

There are several factors to keep in mind when choosing a gripper, but the most important is to be led by the specific application in mind. To help with this, Universal Robots offers its UR+ program, which provides a wide range of grippers specifically designed to handle the most common manufacturing tasks. Nevertheless, there are still some important questions to ask when selecting a gripper for a cobot:

- Will the gripper be handling a single item or a mix?

- What types of items will be handled?

- What shape are the items that the gripper must handle? (Flat, curved or irregular?)

- Is it necessary for the gripper to provide data feedback?

- What payload capacity will the gripper need?

- Will the gripper need to operate in tight spaces?

Related Content

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreJob Shop Discovers and Fills a Fishing Need

The promise of a product line for improved mounting of electronic fish finders led this Missouri job shop to an automated turning process.

Read MoreAutomation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

Read MoreReinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Read MoreRead Next

4 Questions About Cobot Integration

Many shops appreciate that cobots are easy to program and enable collaborative operation, but there might still be questions about how to install them.

Read MoreCobot Fleet Addresses Labor Shortage

An Ohio manufacturer deployed nine collaborative robots to improve and optimize the work environment, automating hard-to-staff tasks such as machine tending, assembly and product inspection.

Read MoreRW Screw: Where Automating Processes is a Common Thread

This Northern Ohio contract machine shop increasingly integrates automation, in all its forms, as it adapts to the reality of a continually diminishing talent pool.

Read More