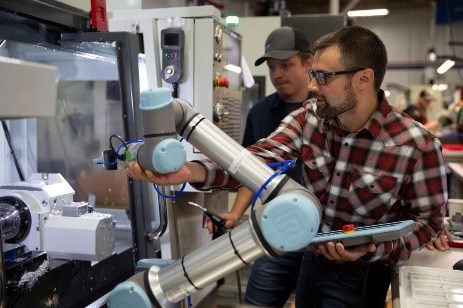

Troy Ojalehto, certified systems integrator at Universal Robots, integrates the UR5 cobot for CNC machine tending at Toolcraft Inc. Some machine shops choose to use an integrator while others do the integrating themselves. Photo credits: Universal Robots Inc.

The integration of collaborative robots or “cobots” has become increasingly popular for machine shops looking for ways to automate machine tending. During the COVID-19 pandemic especially, many companies have realized the significance of automation while they have had to deal with the challenges of social distancing and working around absent machine operators. Others had already begun using cobots to utilize their skilled machinists for more important tasks where the human brain cannot be replaced.

Although cobots vary in design, they all feature some combination of technologies that enable them to function safely alongside humans in a shared area, unlike conventional industrial robots that operate autonomously inside a safeguarded cell. Mostly resembling and functioning like a human arm (having six or seven axes), they are easy to program. Many cobot manufacturers boast that operators need little to no experience with robot programming to successfully set up and program them.

However, companies that have little to no experience with robot integration might have reservations about jumping headfirst into cobot machine tending, as unanswered questions might be lingering. To answer these questions, we talked to Universal Robots (UR), a manufacturer of collaborative robots, to shed light on the basics of installing a cobot.

How do I get the CNC and robot to communicate with each other?

This answer depends on the age of the machine tool and CNC. There are two basic forms of communication possible. For legacy machines, it’s likely through digital I/O (input/output) and relay wiring. This function outputs a signal from the CNC to the cobot, which, in turn, receives it as an input command communicating conditions such as spindle on/off, jaws open/closed, door open/closed and more.

For newer machines, Ethernet communication is most effective for communicating back and forth between the CNC and the cobot, or for sending

For newer machines, Ethernet communication is most effective for communicating back and forth between the CNC and the robot. VersaBuilt offers an Ethernet communication kit that makes connecting the CNC and robot easier.

“handshaking signals.” These handshaking signals are the latest communication form in the industry, and they require a plug-and-play interface that produces an EDS or GSD file to communicate.

VersaBuilt, which is a UR partner, offers Ethernet communication kits called Robot2CNC for select controls (including Haas), which makes installing these connections easier with well-written step-by-step instructions.

Because machine tool technology continues to evolve, the latest machine tools are being built to better support collaborative automation. “Machine tool manufacturers have figured out that this is a key competitive advantage,” says Joe Campbell, senior manager, strategic marketing and application development at UR. “Therefore, they are more accommodating than ever before. They are facilitating the interface rather than blocking it.”

As a result, integration is becoming easier with the latest machine tools, and that ease will continue to grow, adds Karl Sheppard, regional head of customer service at UR.

He believes plug-and-play communication is the most important aspect for many small to medium-sized machine shops to have the capability to quickly integrate these cobots in their facilities. “Bridging the gap for the interface is ultimately the key,” he says.

Do I need an integrator?

Some shops choose to use an integrator (a company that comes on location to integrate the cobot onto a machine shop floor), while others choose to do the integration themselves. It depends on the robot/cobot expertise of the shop and its comfort level with installing a cobot on its own.

Robot integrators have a lot of experience working with different cobot brands, and they are familiar with the different interfaces and installation, Sheppard explains. For first-time cobot users, a shop might feel more confident using an integrator.

However, he believes that machine shops and their engineers can be more critical to the integration process than an integrator because they know their machines and automation needs best.

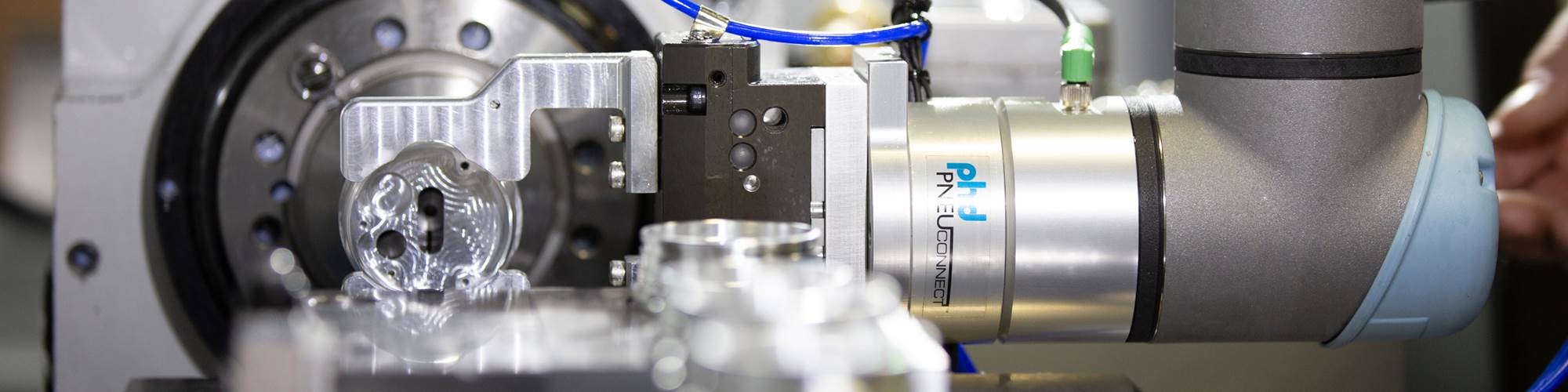

Do I make my own end-of-arm tooling?

Many shops choose to build their own end-of-arm tooling for their cobots because they have that capability in-house. It saves money to make their own, and they find they have control over the quality and design to fit their exact needs.

If a shop chooses not to make its own end-of-arm tooling, there are other options. For instance, OnRobot grippers are UR+ certified, which means they integrate seamlessly with UR cobots, both hardware and software. All control software for the gripper is integrated on the UR cobot's teach pendant.

However, there are other concerns that should be addressed before deciding whether to take on such a project in-house. “You have to consider safety, wiring and communication with the CNC,” Sheppard explains. Knowing how to program or communicate the handshaking commands is critical, he says.

If a shop is not comfortable handling the details that go along with creating its own end-of-arm tooling, purchasing UR+ components is an option. The UR+ Partner Program offers handling grippers developed by different UR partner companies that are customized and certified for UR robots.

Do I need to perform a risk assessment?

Yes. Cobots need a risk assessment just as their traditional robot counterparts do. In fact, the UR cobots have 17 levels of safety protocol, which are adjusted to each individual shop’s unique safety requirements.

Installation adjustments per this risk assessment are much easier with cobots than with robots. “In the past, you’d have a risk assessment, and you’d have to come in and possibly make your fence bigger, move this back two feet, and so on,” Sheppard says about installing traditional robots. “Now, you have a cobot that you can go in and change the force or speed or other different variables within seconds to fit your risk assessment. So, from an ease of integration standpoint, you literally can make changes, software-wise, that turns into hardware, and you're up and ready to go within hours.”

Cobots are known for their ease of programming and use. This cobot teach pendant is not only user-friendly but also dust- and water-resistant.

For an inexperienced shop that has not done a risk assessment for automation, Campbell recommends visiting the Robotics Industry Association (RIA) website, robotics.org, to take the fundamental training on robot safety and risk assessment it offers prior to beginning the risk assessment process.

“The RIA has cost-effective training packages,” Campbell says. “However, if you don't have anybody on your team who has time to do this, then maybe you should go outside the company. The RIA has a collection of skilled consultants who will visit a company to help.” He recommends possibly hiring a consultant for the first cobot integration, and then after the first experience, a shop is likely to understand the process and will not need to hire a consultant the next time.

Technical specification ISO/TS 15066:2016 is another good starting point that helps facilitate cobot integration. The specification offers guidance to conduct more sophisticated preliminary risk assessments of both the cobot system and the environment it will share with humans.

Universal Robots USA Inc. | 844-462-6268 | universal-robots.com

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreTips for Troubleshooting and Repairing Chip Conveyors

A nonfunctioning chip conveyor can cause a high-production machine to be down for an extended period of time. Here is some troubleshooting advice if you’re having issues with your chip conveyors.

Read MoreRead Next

Cobot Fleet Addresses Labor Shortage

An Ohio manufacturer deployed nine collaborative robots to improve and optimize the work environment, automating hard-to-staff tasks such as machine tending, assembly and product inspection.

Read MoreCobots Gain Ability to Sort and Measure

New tooling that includes a precision robotic caliper extends the applicability of collaborative robots to perform sorting and measuring small parts.

Read MoreA Hands-On Approach to Cobot Gripping

As humans and robots begin to work closer together, grippers that have the flexibility of the human hand will be more in demand.

Read More