Craftsman Cribsheet No. 105: Yield Loss Due to Bar End Remnants

Yield loss on raw materials can become a hidden way of losing money in your shop. Using a chart and sample calculations can help you better understand why you might be better off buying longer bars for your process to reduce yield loss dollars.

As material costs continue to rise (Producer Price Index shot up 9.7% January 2021-January 2022), yield loss on our raw materials can become a hidden way of losing money in your shop. Use the chart and sample calculations to better understand why you may be better off buying longer bars for your process when available to reduce yield loss dollars.

- Minimizing the length of the bar end is important, but due to fixed bar length availability from our suppliers, it may be difficult for us to control.

- One way to minimize the loss due to bar ends is to purchase the longest bars that your process can accept. This lowers the percentage loss for a fixed length of bar end.

- Another way to minimize bar end loss could be to reduce cutoff tool width, which may enable additional parts to be produced, reducing the length of the bar end.

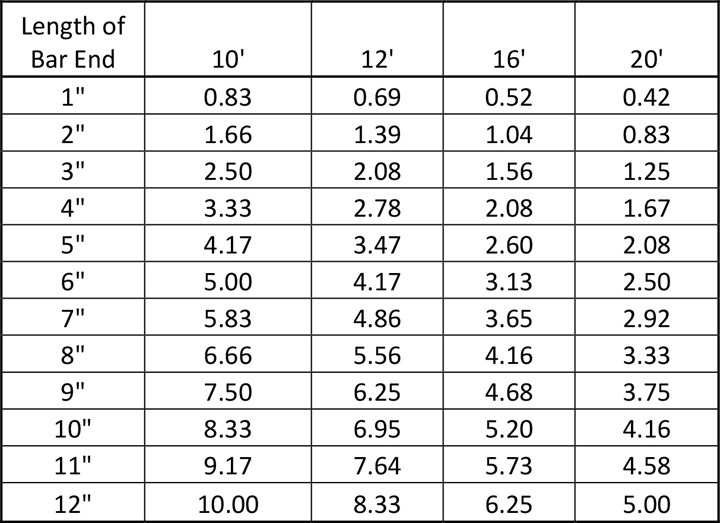

Percentage Loss Due to Bar Ends

Example: Increasing Bar Length

A 5-inch bar end is required by your equipment. The material price is $0.795 per pound. You are ordering 10,000 lbs of bars for the job.

The cost of yield loss for 10-foot material given a 5-inch bar end is 4.17% times 10,000 lbs times $0.795 = $417

To calculate the savings by using longer bars, subtract the new yield loss from that of the 10-foot bars.

Increase bar length from 10 feet to 12 feet

- Yield loss on entire lot if 12-foot bars: 10,000 pounds times .0347 times $0.795 = $347

- Increasing bar lengths from 10 feet to 12 feet saves the company $417 minus $347 = $70 of unneeded yield loss.

Increase bar length from 10 feet to 16 feet

- Yield Loss on entire lot if 16-foot bars: 10,000 lbs times .0260 times $0.795 = $260

- Increasing bar length from 10 feet to 16 feet saves the company $417 minus $260 = $157 of unneeded yield loss.

Increase Bar length from 10 feet to 20 feet

- Yield loss on entire lot if 20-foot bars: 10,000 lbs times .0208 times $0.795 = $208

- Increasing bar lengths from 10 feet to 20 feet saves the company $417 minus $208 = $209 of unneeded yield loss.

Using longest lengths of bar stock available can reduce your yield loss due to bar ends substantially.

Related Content

-

Do You Have a Quoting Process?

The only way to have repeatable results is to have a process.

-

Keeping It In The Family — Succession Tips From Those Who Lived It | Part 1

PMPA members share some tips to avoid getting burned when passing the business torch from one family member to another.

-

Craftsman Cribsheet No. 121: ISO Turning — What Does it All Mean?

How to make sense of all those different letters and numbers in ISO turning inserts.