Diamond Lapping and Lapping Plate Control

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.

Diamond lapping might be appropriate for machining/finishing operations that face challenges such as greater planar, spherical or conical surface requirements; improved sealing; improved cosmetic surfaces; planarizing joined dissimilar materials (for example, laminates, composites); surface deburring, removal of “gummy” materials; super-hard materials that are only economically processed with the use of diamond; and thinning/finishing poor aspect ratio parts.

Common industrial applications for diamond lapping include mechanical seals, seal rings, valves, stamping dies, pump bodies, slitter blades, gage blocks (“Jo-blocks”), micrometer spindles, fuel injection valves, dies/gaskets, CD molds, mirrors and micro electro-mechanical devices (MEMs). Almost any material can be lapped, including steel, stainless steel, chromium carbide, tungsten carbide, aluminum, copper, bronze, Alinco (aluminum-nickel-cobalt), ceramics, glass, sapphire and plastic.

What is Lapping?

Lapping involves a medium (superabrasive and associated paste or liquid carrier) that is applied between the workpiece surface and a lapping plate.

While some of the diamond particles become embedded in the lapping plate to perform a fine grinding action, abrasive particles in lapping may also be continuously loose and rolling “free particles” see Figure 1. Lapped surfaces do not have directional marks. The lapping process works by pushing the points of the diamond grains into the work surface to abrade microchips of material. Imagine this kneading or abrading action on the work surface being repeated millions of times over to produce effective material removal, as well as provide a simultaneous polishing action (especially when using abrasive particles as fine as 50 nm).

To gain the full benefit of the inherent strengths of diamond as an abrasive, the ideal lapping machine design features high down-pressure/down-force

(5 psi and higher), has a robust drive system to tolerate the high down-pressure used and a variable speed drive with high top-end RPM capability.

Compared with lapping with conventional abrasives such as aluminum oxide, lapping with superabrasives offers the following benefits:

• Aggressive material removal for equal or better productivity

• Uniform edge-to-edge flatness; sub-light band (11 millionths inch) results are routine; as high as 1/20 wavelength is achievable under specific conditions

• Better than sub-micron surface finish (< 0.5 Ra) is routine; sub-nanometer surface finishes are achievable

• High potential to develop a one-step lapping and polishing solution for reduced cycle times

• Reduced waste to support green initiatives

System Approach

With the need to meet objectives relating to statistical process control, six sigma, lean and green initiatives—coupled with ever-increasing cost pressure—companies need to continuously re-examine all of their machining and finishing processes. When it comes to fine grinding and lapping, best results occur by taking a systems approach that examines machine tools, abrasive powders and slurries, plates/pads and accessory options and matching them against specifications for consistent part quality, processing time, environmental requirements and overall costs.

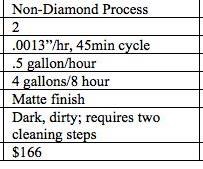

As shown in the ceramic parts case study (see Figure 2), diamond superabrasives provided a more effective solution. It eliminated the hand-polishing step, reduced cycle time by 30 minutes, saved $14.87 per hour in slurry costs, reduced slurry waste and associated disposal costs, reduced cleaning time and reduced use of cleaning solutions. Lower-volume requirements for diamond slurry also reduced shipping and inventory costs.

Maintenance Considerations

Lapping plate maintenance with superabrasives differs from conventional lapping, which usually uses a cast iron plate. Superabrasives typically use a composite metal lapping plate made from tin (TX-10A), copper (HY Cu) or iron (X-08). After a certain period of use, the lapping plate becomes worn and requires reconditioning to re-establish plate flatness to meet end-part tolerance, as well as meet surface finish requirements. Plates also become “glazed” and no longer remove material at a consistent rate, which in turn, introduces undesired production variables.

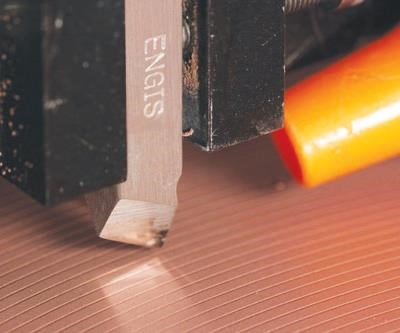

Reconditioning a diamond lapping plate requires cutting away the top surface to restore flatness and retexturing the plate so that it can be “charged.” Charging is the process of embedding diamond abrasive into the plate (embedded or “fixed” diamonds).

Until Engis developed its FastLap Facing Device, reconditioning involved using diamond-plated conditioning rings and the experience of a highly skilled operator. While results are satisfactory, it is a demanding task, resulting in excessive machine downtime and unpredictable production losses. Optical micro-graphs and image analysis software reveal that this process imparts a random texture and an uneven “bearing ratio” (the percentage of surface area with which the workpiece will ultimately come in contact).

A facing device uses a diamond tool bit to remove the top (worn) layer of the lapping plate, machining it flat to within microns. To produce a controlled surface geometry and texture, the device then makes a second pass, which machines a groove pattern (see Figure 3) that serves as the basis for structured embedding of abrasive particles.

Controlling the groove pattern (macro texture) and lands (micro texture) of the plate surface allows for more consistency in removal rates and surface finishes. A consistent bearing ratio means consistent unit load, repeatable removal rates and excellent batch-to-batch consistency. The reduced contact area provided by a grooved plate increases the load per unit area, therefore increasing removal rates. The groove also aids in clearing away swarf.

The development of facing devices was driven by the need to increase first-pass quality and reduce scrap costs in the electronics industry (imagine the cost of scraping sapphire optical components and semiconductors), but the precision machining industry can benefit, too. If a company determines that superabrasives would add benefit to its operations, a facing device eliminates concerns about finding an operator with the skills to maintain a plate using traditional techniques, thus simplifying the integration of a diamond lapping system.

With lapping, it is important to remember that consistency is the key to success, and successful companies make every effort to control the bearing area, pressure, platen speed, charging process and dispensing of slurry. Controlling these variables leads to more uniform surface finish, stock removal rate, flatness or desired contour, part size/thickness and planarity—and customer satisfaction.

Related Content

The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreJunker Grinding Machines Feature Modular Design

The Platform 3 series of modular grinding machines is designed to provide increased flexibility and cost-effectiveness.

Read MoreTooth Flank Grinding Technology Minimizes EV Drive Noise

Drives for electric vehicles require gear components with tight tolerances and excellent surface finishes. Even minimal ripples in the surface of tooth flanks on shafts and gears can cause interference noise in drive performance.

Read MoreGrindstar Replaces Turning With Efficient Grinding

PMTS 2023: The Grindstar machine uses a method that enables the entire workpiece contour to be ground in a single processing operation.

Read MoreRead Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)