Workholding can affect many aspects of the machining process, but it often is not given enough attention. Many shops are content to use whichever workholding system comes with the machine. If it gets the job done, they don’t give it another thought—unless they have to. But once a shop does take a closer look at its workholding, it can lead to improvements in several different areas of the part production process.

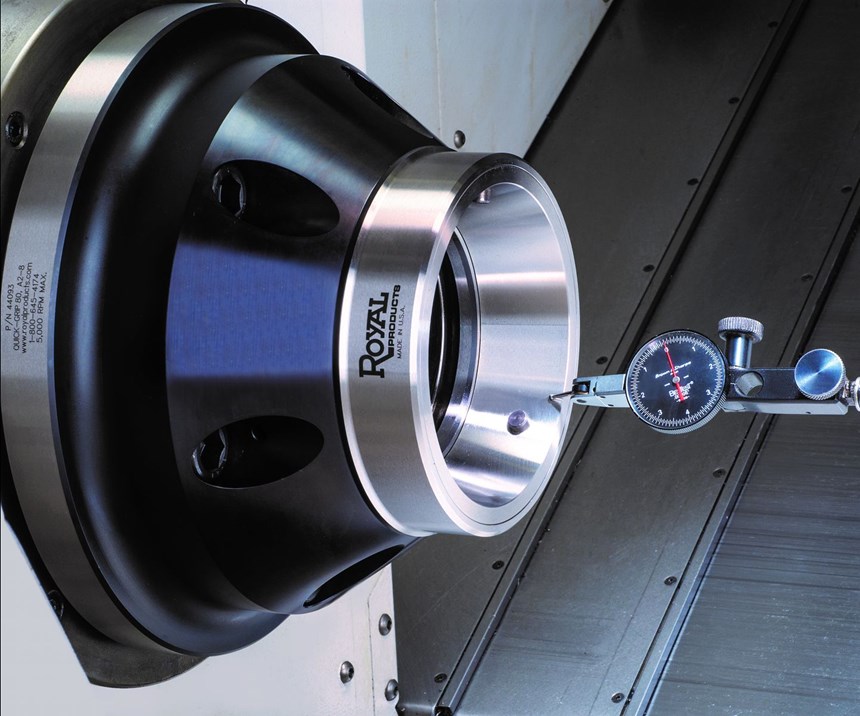

One such workholding option is a collet chuck. To get more information, we spoke with Matt Block, a regional business manager with Royal Products. Royal provides a range of workholding options, including several lines of collet chucks.

Collet chucks are traditionally thought of as an effective workholding solution for applications involving bar feeders, small diameters and thin-walled, delicate or irregularly shaped parts. But collet chucks can also provide a range of benefits that apply to shops that produce other types of parts.

Fast Change-over

Almost every shop running more than one job on a machine could benefit from reduced change-over time. According to Mr. Block, reducing setup time for workholding is often overlooked, but possible to accomplish. “One of the reasons many shops have not pressed into this area is related to part accuracy,” he says. “Increasingly, part tolerances have become tighter and more difficult to achieve, and the common school of thought dictates that one must freshly cut the jaws on a three-jaw chuck to have any hope of holding 0.001 inch total indicated runout. This is a process that can take 25 to 45 minutes or more, depending on the job and skill level of the person involved. Reducing that time to 10 seconds with a TIR of 0.0004 inch puts the machine in the position of making more parts.”

Royal has a line of collet chucks that is specially designed to provide fast change-over. The Quick-Grip (QG) system includes a special tool that enables users to quickly switch collets. The tool has a series of steel pins that pick up and compress the collet. The user can then position the collet in the machine and release the collet to install it.

Compared with a conventional collet chuck, which requires users to thread in a collet and then find a groove to lock into with a set screw, the Quick-Grip’s collet changing tool is not only faster, it helps improve repeatability between operators. “You don’t have the inconsistency of one operator’s feel and how well it’s set up versus another, so any operator can achieve the same results when it comes to setup time,” Mr. Block says.

Increased Gripping Range

According to Mr. Block, the Quick-Grip collets also have a wider gripping range than traditional collets. This is because the Quick-Grip collets use vulcanized rubber between the metal segments to open and close instead of the spring-type action used by conventional collets. “That allows for more freedom of movement,” he says.

The wider gripping range of the Royal Quick-Grip collets enables customers to run materials with higher variances and still achieve the benefits of using collet chucks. Mr. Block gives hot-rolled steel barstock as an example. While it is often a less expensive material, the diameter varies more than conventional collet chucks can handle (typically ± 0.010 inch) and the inherent scale on the outside can cause conventional collet chucks to jam up. The ± 0.031-inch gripping range of Quick-Grip can help customers run this material profitably.

Another way shops can take advantage of the wide gripping range is by performing two machining operations using the same collet. If a part’s roughed and finished diameters are close enough to be held in the same collet, users can flip the part and clamp the second diameter without having to change the collet. “This is how some shops move into single-piece flow versus batch and work-in-progress operations,” Mr. Block says.

Accuracy/Rigidity

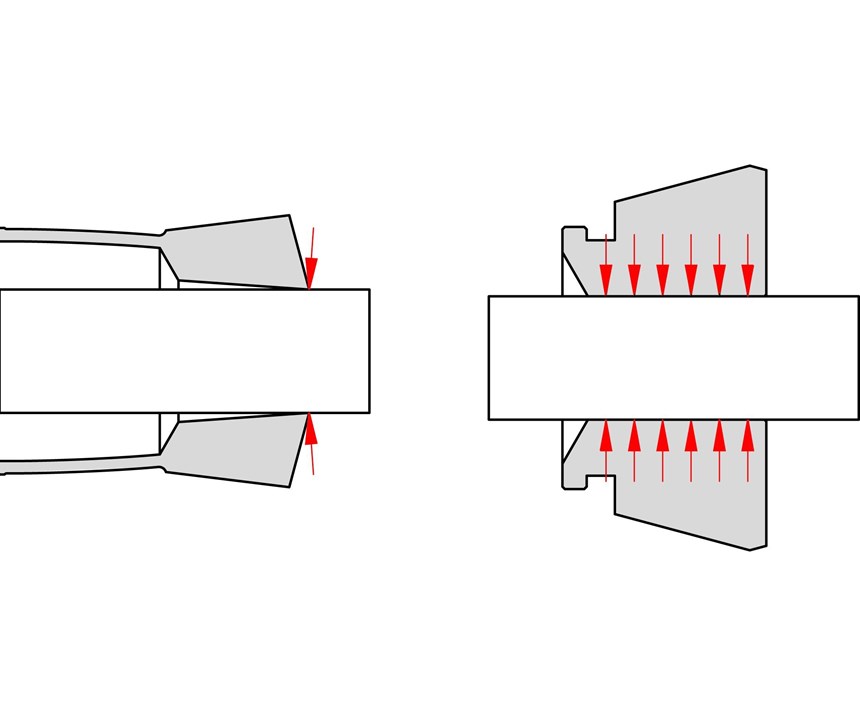

Collet chucks can also improve the quality of parts being produced. These systems have full contact with the workpiece, as opposed to a three-jaw chuck, which only has three points of contact with the workpiece. The vulcanized rubber in the Royal QG collets provides parallel clamping along the entire portion of the workpiece inside the collet, compared with conventional spring-action collets, which only pinch the part at the end of the collet. “That’s where we get our accuracy and additional rigidity,” Mr. Block explains.

Accurate and rigid workholding is essential to most machining processes. Increasing the accuracy of the workholding system not only enables the production of highly accurate parts, it can also increase tool life. “If the part is more accurately and consistently placed in the exact same position, the cutting tools have a predictable chip load and can be optimized for longer cutting life,” Mr. Block explains. The increase in cutting tool life can reduce tooling cost per job. An increase in rigidity without sacrificing accuracy also enables users to increase speeds, feeds and depth of cut. Increasing the material removal rates reduces cycle times, which in turn increases throughput.

Reduced Maintenance

Finally, the Quick-Grip collet system requires less maintenance than a three-jaw chuck, according to Mr. Block. “Three-jaw chucks typically require lubrication at least once per day, and, depending on use, as often as every six to eight hours of operation,” he says. “Failure to grease a three-jaw chuck can result in a significant reduction in applied clamping force. Most collet chucks do not require the same level of attention, and the Quick-Grip chucks are greased and sealed from the factory.”

The other cause of chuck maintenance is chip contamination. “Chips are probably the most clever items in any given shop—they always seem to get into exactly where you don’t want them,” Mr. Block jokes. Cleaning the chips out of most three-jaw chucks can cause significant downtime on the machine. And this problem is not unique to three-jaw chucks—conventional collet chucks are also prone to having chips packed between the collet segments. When chips build up in the workholding system, the chuck’s clamping ability is reduced until the chips are removed. The vulcanized rubber between the segments of the Quick-Grip collets helps prevent chip contamination. “While nothing is 100-percent impervious to chips in a machine, this system is a significant step above the alternatives when it comes to reducing maintenance,” Mr. Block adds.

Putting It All Together

The benefits of collet chucks are illustrated by one of Royal Products’ customers, an Illinois-based equipment manufacturer.

The company has set up cells in different parts of its machine shop to produce different components. Within these cells, one employee is responsible for running several machines, which include CNC and manual lathes, robotic and plasma welding, fabrication, horizontal machining centers, vertical machining centers, and five-axis machines, along with an assembly department. About 40 employees work in the 70,000-square-foot machine shop across two shifts.

Some of the parts produced by the company have bearing journals with tight tolerances. These parts need to fit together with other parts, and in some applications the clearances can be as little as 0.003 to 0.004 inch. Runout is another issue, as it can ruin the functionality of the final product.

All of the shop’s lathes had the same three-jaw, soft-jaw, quick-change chucks. Eventually, the chucks on the two lathes used for finishing operations began to wear out and rebuilding them was not an option. Once the company realized that it was going to have to spend money on a new workholding system, it reached out to its distributor, who recommended the Quick-Grip collet chuck system from Royal Products.

Initially, some of the company’s employees were skeptical about switching to a collet system. There was some concern about how collet chucks would affect change-over time. But once the employees saw a video of the Quick-Change collet chucks, they became convinced that the system could work for their needs.

The shop started off by installing the new workholding system on one of its machines for a three-month study. The company was able to see that the collet system was a success, so it implemented it on the second lathe. In the year or so since the company has been using the system, it has seen improvements in several areas.

The biggest benefit the company has seen since switching to the collet system is reduced change-over time. Changing a part on the old system required the operator to adjust the jaws, move the tailstock and occasionally turn the soft jaws so they would stay true. With the collet chucks, the operator only has to unplug the old collet, plug in the new one and adjust the tailstock.

Unlike the jaw chucks, the new system also requires less maintenance, which has contributed to increased efficiency. The shop’s employees no longer need to turn the lathes’ soft jaws to ensure they remained true, which they described as a “constant battle.” The soft jaws also required greasing every day, which the collets do not, saving additional time.

In addition to time savings, the company has reported an improvement in part quality. It has also seen less rework and scrapped parts since implementing the new system.

Related Content

Bar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

Read MoreWorkholding Facilitates Fast Changeovers for Robotic Surface Finishing Systems Manufacturer

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

Read MorePrecision Machining Technology Review: December 2024

Production Machining’s December 2024 technology showcase includes some of the latest technology from Hexagon, Kennametal, SmartCAM, Horn and SMW Autoblok.

Read MoreWhat’s the Right Bar Feeder for Your Machine Shop?

Machine shops likely have questions about what type of bar feeder makes most sense for their operational needs. One or more of these four might be floating around in your head.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)