E-Mobility — Opportunity, Not Existential Crisis

“We firmly believe that e-mobility presents a significant opportunity for innovation and growth.” — Markus Horn

I recently had the opportunity to speak one on one with Markus Horn, CEO at Paul Horn GmbH in Tubingen, Germany, at their June 2023 Technology Days event. Knowing the importance of the conventional internal combustion and diesel markets to Horn’s precision tool manufacturing, I asked for his critical thinking on the threat of the move to e-mobility to the company. The critical thinking and outline of different facts raised by Markus is a welcome change that helps us look through the hype of the “inevitability of e-mobility” to see a much different vehicle market in the future than the media would have us believe.

Full disclosure — I have been a proponent and early adopter of e-mobility. My first white paper for PMPA in 2003 was about 42-volt hybrid auto technology. I am a delighted EV owner.

In the United States, the automotive industry is the largest market served by our precision machining shops. The automotive industry plays a crucial role in the global economy, with approximately 100 million vehicles produced worldwide each year. Knowing that just one of Horn’s insert lines (the 312) alone had created more than 1,165,071 miles of piston grooves for internal combustion engine (ICE) for automobiles — the equivalent of cutting your way 147 times around the Earth or flying to the moon and back nearly five times — I expected some fear of e-mobility’s impact on the company and our industry.

I was pleased when Markus Horn stated that, “While some perceive this transition as an existential crisis for traditional automotive manufacturers, we firmly believe that e-mobility presents a significant opportunity for innovation and growth.” So much for the inevitable loss of our legacy internal combustion vehicle market.

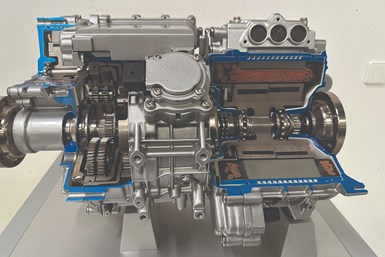

Comparing the number of parts on an ICE vehicle to an electric vehicle (EV) highlights another aspect of the shift toward e-mobility. Traditional ICE vehicles consist of numerous complex parts, whereas EVs have significantly fewer components. This reduction in parts not only simplifies the manufacturing process but also provides an opportunity for streamlining production and reducing costs. But decreased parts counts could mean reduced production in our shops.

Markus refuses to be pessimistic about potential decreased parts. One of the key opportunities for innovation and growth in the transition to electric vehicles is the need for greater precision in sealing and rotating surfaces to reduce vibration and noise. The sounds created by the equipment for controlling battery, motor and cabin thermal management are no longer hidden beneath the din of the engine and gear train noise as in legacy ICE autos. This requirement creates a demand for advanced manufacturing tools, and it is in this application that companies like Horn have a substantial role to play.

While the increasing electrification of vehicles presents numerous benefits, it also poses certain challenges. One of the key concerns is the consumption of copper, a vital component in electrical systems. In 2022, global copper consumption stood at 25.1 million metric tons, with the U.S. accounting for 1.9 million metric tons. Forecasts predict a further increase in global copper consumption to 29.19 million metric tons by 2027, a 16.92% rise. This surge in demand necessitates the development of efficient copper recycling and supply chain management systems to meet the needs of the e-mobility market. But difficulty with the supply of copper and other e-materials could constrain the growth of e-mobility.

Furthermore, the transition to EVs highlights infrastructure limitations and energy supply intermittency issues. Markus points out that in Germany, for example, the housing stock’s electrical service is not currently capable of supporting the load required for widespread EV charging. In multiple domicile buildings, perhaps only a fraction of the residents will be able to have charging equipment installed, due to the limits of the building’s electrical service. Additionally, the grid in Germany, which has replaced baseline nuclear power with coal (needed because of the intermittent nature of solar and wind power) faces challenges in supporting the charging infrastructure effectively. And what is the climate sense of replacing carbon-free nuclear with coal?

Addressing these challenges requires a multifaceted approach. Markus has done the math. While battery storage can help relieve intermittency issues, it also adds challenges and obstacles to investment. These include additional energy losses at the battery and potentially prohibitive payback periods/ROI declines on investments. No one expects technology and innovation to remain at current levels, but we are not seeing any dramatically more efficient energy storage solutions or advancements in renewable energy generation in the immediate future.

It is important to note that the decision to transition away from internal combustion engine vehicles by 2035, as ordered by the European Parliament, does not solely determine market dynamics. Markus is emphatic that market demand is primarily driven by customers rather than officials. While it is essential to consider regulations and policies, they must be aligned with the ever-evolving needs of the customers and the realities of the national infrastructure and technology deployed.

Horn, as a leading player in the automotive tooling industry, embraces the opportunities presented by e-mobility. It understands that standing still is not an option in today’s rapidly evolving automotive landscape. By focusing on science rather than politics, Markus recognizes there is an alternative to the “e-mobility is inevitable, winner-take-all,” paradigm. He points out that a combination of diesel and hybrid technologies currently offers the best and cleanest transport solution. While the current regulations have ordered no further ICE vehicles by 2035, he sees no reason to panic.

“The officials in the Parliament in 2030-2035 will have different facts and different agenda. The logics they have then will certainly differ from our logics today. The regulations of today reflect the desires of today, not the realities of the future. An all-electric transportation system is neither inevitable nor likely when one gives an honest review of the facts.”

Markus sums up, “We are at the most technological point that you can reach today, and we are organized to lead the next needed developments in all mobility, not just e-mobility. Our tools and processes continue to evolve to serve applications in other areas impacted by the waves of demographic change and progress globally. We are optimistic that together we will continue to develop and master the tools needed to embrace the technological advancements and new developments in physics that will shape the future — not just of mobility — but of our world.”

E-mobility is an opportunity, not an inevitable, existential threat. If you think carefully about the facts, and the value that we all can add, our very best will continue to lead to solutions that will improve our quality of life and sustainability.

Read More Articles from PMPA:

- Roles of Women in Manufacturing Series: Manufacturing Shop Owners — Adria Bagshaw and Tanya DiSalvo

- Craftsman Cribsheet No. 118: Put A Little Shine In Your Day

About the Author

Miles Free III

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email – mfree@pmpa.org; website – pmpa.org

Related Content

Onshoring Weather Report: Strong Tailwinds!

Onshoring, reshoring, nearshoring: these terms are showing up with increasing frequency in the news and online. But is there evidence that these are real?

Read MoreCraftsman Cribsheet No. 119: Defeating the Hanging Cross-Hole Burr

Deburring is a tedious task that is better left to machines.

Read MoreDo You Have a Quoting Process?

The only way to have repeatable results is to have a process.

Read MoreCraftsman Cribsheet No. 121: ISO Turning — What Does it All Mean?

How to make sense of all those different letters and numbers in ISO turning inserts.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)