5 Steps to Digital Manufacturing

Industry 4.0, what some call the Fourth Industrial Revolution, is a move made toward digitization.

Industry 4.0, what some call the Fourth Industrial Revolution, is a move made toward digitization. Also known as the Industrial Internet of Things (IIoT), this combination of industry and the Internet of Things (IoT), embeds physical devices with network connectivity to facilitate data exchange among the devices.

IIoT incorporates machine learning and big data technology in digital manufacturing, bridging the digital and physical worlds by harnessing sensor data, machine-to-machine (M2M) communication and already existing automation technologies. The driving philosophy is collecting data that’s already in CNC machines, enabling companies to identify inefficiencies and problems sooner, saving time and money and supporting business intelligence efforts.

This ongoing capability has important implications for cybersecurity professionals, networking specialists and the manufacturing industry as a whole. As a result, the industry is abuzz. However, there are also many misconceptions and misunderstandings that can cause shop owners to hesitate implementing IIoT on their shop floors.

Our recent discussion with Ron Pieper, manager of VizProducts at TechSolve Inc. (Cincinnati, Ohio) may help to alleviate many of those concerns. According to Mr. Pieper, “The core of digital manufacturing can be summed up in simple terms, and that is gathering, analysis and application of data.”

Manufacturing Communications Protocols

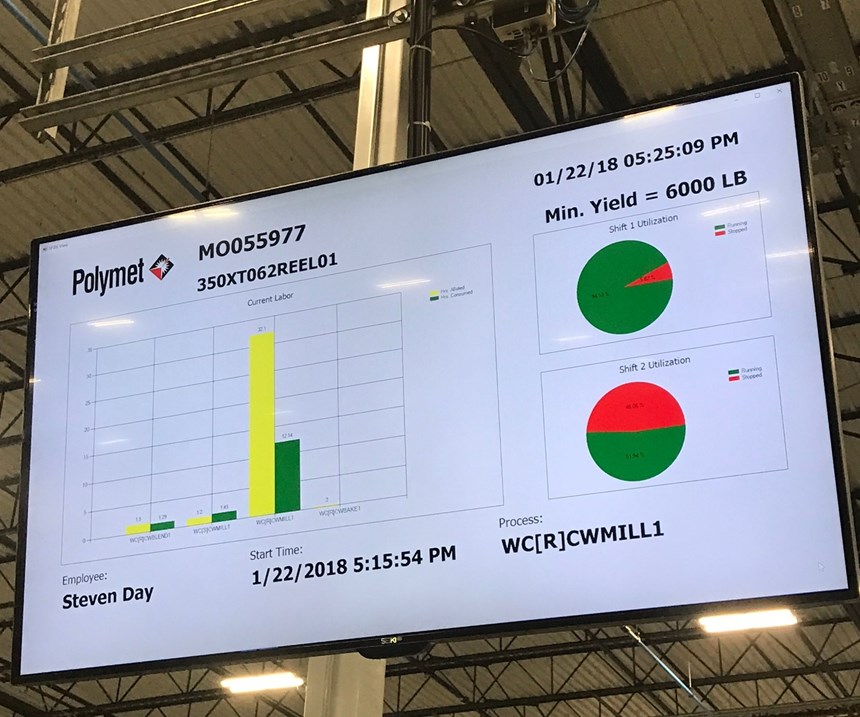

TechSolve’s foundation for digital manufacturing is MTConnect, a protocol designed to promote data exchange by retrieving process information from CNC machine tool controls and sharing it among other shopfloor equipment and software applications, including VizProducts adapter software and machine monitoring services used for data analysis. VizProducts, including the MiniViz, ShopViz and VizAdapters, allows MTConnect compatibility and handles data exchange from a variety of machines, as well as sensors and human interface devices.

Control technology, the brains behind machine tools, is always advancing, but around the turn of the millennium, there were significant changes in the way information contained in the control might be shared. With this evolution, there will be challenges, both with legacy technology and with bending the brains of a hesitant workforce. If a shop is considering what digital manufacturing is, how they can get into it, and why they should get into it, several factors should be considered.

Convince People

One challenge in the data-gathering process is pushback from those who feel they are being scrutinized. In many shops, personnel may say they’ve never done digital manufacturing before and they’re making money, so why change things?

The answer, of course, lies in the advantages digital manufacturing can bring to a shop, whether that be with legacy machines or with the latest technology. If the data is there, why not take advantage of it? But it really depends on what a shop wants out of the system.

Get Your Swing Down

CNC data, sensors and advanced analytics can predict when machines need maintenance, thus reducing unplanned downtime that cuts into production time. Accessing data to improve field service scheduling as well, ensures that the right technicians and tools are dispatched before potential issues become a major problem.

If a shop can gain a significant production advantage from monitoring existing machine technology and facilitating best practices, the need for a machine purchase may be delayed for a while. And it makes sense to find ways to get the most from this existing equipment before moving on to something new when that change may not fix certain underlying issues.

A golf analogy can be used to better illustrate the significance of understanding everything involved in improving the process. A golfer should learn how to swing the clubs he has before running out to buy better ones. No matter what top-of-the-line driver is used, the ball will still end up in the weeds if it isn’t hit straight.

Mastering the process first is the key. In golf, once flaws in the swing have been corrected, new clubs may be the next step to improving a person’s game. In manufacturing, increasing capacity or the need to replace older or failing equipment may justify purchasing new machines. Data can provide solid evidence for when and why to invest in new equipment.

Make Simple Changes

Regardless of automated monitoring systems, employees are still the most important element of a shop’s success. “Those that implement and maintain best practices on a daily basis, at the shop level, are where true improvements are made and maintained,” Mr. Pieper says.

Better managers, for instance, can offer easy solutions, often simply by knowing when a machine is off, when it’s on and what the program overrides are. Fortunately, a significant part of machine monitoring—systems that are easy to train on and generally only take a day or so to be set up—is that it provides data-based insight on these factors.

Insight into when a machine is on or off proved useful in a recent instance when TechSolve provided a monitoring system to robotic weld cells for a shop. Rather than revealing any sort of complex problems, the monitoring showed that employees were taking too long for machine startup and too long for breaks. Simple problem, simple solution.

The same is true with keeping up with overrides. MTConnect and VizProducts can track operator-initiated feed and spindle speed overrides. They also track other items such as optional and programmed stops on machines. Supervisors can receive an alert if an attempt is made to override or circumvent the programmed values and act accordingly.

By communicating with the client application, the control and sensors can help to improve machine usage and reduce material and time wastes.

Choose a Maintenance Style

The implementation of digital technologies can be the difference between planned and predictive maintenance. But predictive data is different than a simple management style.

With the former, more theoretical approaches to digital manufacturing have caught on in recent years. But most problems are simple—broken cables, faulty switches, and human error. Typically, speculative sources of downtime and part quality issues are not as important as better training and machine awareness.

A management style, however, is simply about what machines are running and what machines are not. This approach requires a baseline method to collect data from the range of a shop’s installed equipment that is consistent across legacy machines as well as those that have been brought in recently.

Looking at what affects cycle time is an old-school approach, and that has started to change in the last six or seven years. Taking the subjectivity out of the data, the focus can be on machine performance instead of operator performance.

Consider Cybersecurity

The question of cybersecurity often arises during discussions of digital manufacturing. When moving toward digitalization, risk of vulnerability needs to be considered. Because cybersecurity is such a rapidly developing industry, it’s crucial for professionals in IIoT, specifically, to keep abreast of new security concerns.

To reduce the risk of hacking, networks need to be isolated from external attacks. For example, if anyone were to hack into collaborative robots meant to be integrated with lathes, mills, routers or grinders while they are being operated, that security breach could spell disaster for the machinist currently using the cobots.

Long-Term Ramifications

Incorporating digital manufacturing requires coordination, convincing hesitant employees and a willingness to evolve with the changes the technology brings. Interfacing legacy machines, new machines and sensors will enhance the functionality of both machine and software by bridging the digital and physical worlds while enabling everyone on the shop floor to work together more efficiently as a team.

Mr. Pieper believes the future lies in the use of data for a new angle on plant efficiency and that means TechSolve is going to continue helping shops collect, store, integrate, analyze and share that data.

Related Content

When CNC G-Code Programming Is a Must

In some cases, G-code programming is preferred over conversational programming, although they can be complementary processes.

Read MoreAvoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MorePrecision Machining Technology Review October 2023

Production Machining’s October 2023 technology showcase includes some of the latest technology from Tungaloy-NTK America Inc., Renishaw, Walter USA, Seco Tools and Haimer USA.

Read MoreThe Control’s Role in Machining Complex Parts

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Read MoreRead Next

Preparing Precision Turning for Industry 4.0

Ready or not, Industry 4.0 is moving forward, and it’s critical for manufacturers to be ready for it. Many machine tool builders and accessory builders are equipping their products with Industry 4.0 compatibility in anticipation of its implementation by customer shops.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)