For manufacturers with high precision cleaning requirements, is your parts cleaning process ready for potential changes and disruptions soon? Because the U.S. Environmental Protection Agency is currently reviewing the use of classic halogenated solvents in industrial parts cleaning, it is possible that their use could be further limited, resulting in the need to find alternative cleaning solutions.

Non-halogenated solvents such as modified alcohols can be reliable replacements for the solvents under scrutiny. Modified alcohols, which have been around for more than two decades, have good drying qualities, are very stable and have a low surface tension, making them especially useful for cleaning tiny or complex parts with small crevices.

Contrary to halogenated solvents, modified alcohols do have a flashpoint. Therefore, they must be applied in vacuum-closed cleaning machines (airtight/airless degreasers). The initial capital expenditure might be seen as a hurdle. However, the much higher cost efficiency these machines can enable is a worthwhile investment that pays for itself in a relatively short amount of time.

High Standard of Cleanliness

Effective in meeting the most discerning cleaning requirements, modified alcohols are deployed in industries with the most critical safety and quality requirements, including aerospace, automotive, medical and electronics.

Produced synthetically, modified alcohols are remarkably stable in temperature and pH. Because of their polar and non-polar properties, modified alcohols can remove non-polar contaminants such as oils and greases just as effectively as certain polar contaminations such as cooling emulsions or solids such as particles and abrasives.

Effective for the most critical cleaning requirements, modified alcohols have very good drying properties. Their low surface tension makes them especially useful for cleaning blind holes and crevices easily.

Photo Credits: Safechem

Modified alcohols have universal compatibility with metals and very good drying properties. Due to their low surface tension, they can wet into and evaporate out of blind holes or crevices easily, making them a highly effective cleaning agent for tiny or complex component parts. Compared to traditional non-polar solvents, modified alcohols offer a distinct advantage in removing a wider range of contaminants and therefore have a much broader application range.

Particularly in the aerospace sector, there are no risks associated with hydrogen embrittlement of titanium or aluminum. This is a critical advantage considering that the only option in the past to avoid this was to adopt water-based systems.

Environmental Protection in an Airtight Degreaser

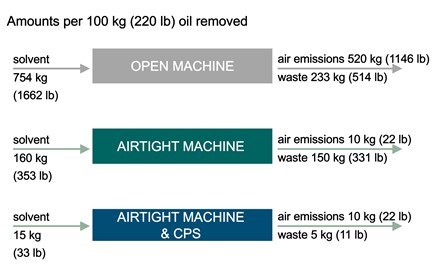

Consider a scenario where 100 kg of oil needs to be removed – the deployment of an airtight degreaser can dramatically reduce the solvent consumption of perchloroethylene by almost 5 times, from 1,662 lb to 353 lb compared to an open machine (see Fig. 1). With the support of Chemical Product Services (CPS), such as consistent solvent monitoring and stabilization, the amount of solvent required can drop even further from 353 Ibs to a mere 33 lb.

Fig. 1. Source: Chemical product services in the European Union, European Commission, January 2006

Safety standards and environmental protection are heightened at the same time. Operators have virtually no contact with the chemical, air emissions are kept to a minimum and waste volumes are being optimized.

Through the distillation unit equipped in a closed cleaning machine in which modified alcohols are suited, the used solvent can be continuously distilled and purified. Because of their narrow boiling range, these solvents can be more easily distilled and separated from contaminants and hence more effectively recovered during the distillation process.

The reuse of the solvent over multiple cleaning cycles significantly reduces solvent consumption and waste while lowering overall cleaning costs. Through continuous monitoring of the solvent condition and the addition of stabilizers, solvent lifespan can be extended still further. When comparing this to an aqueous-based system, the environmental impact can be significantly reduced due to no additional energy required for drying components and no water needed for cleaning, making solvent cleaning much more resource friendly.

The Right Solvent for the Right Application

Besides modified alcohols being particularly suitable for use where high standards of cleanliness are demanded, they are also useful where a high material throughput is important. Particularly for subsequent processes that demand high surface tension of the metal surface, such as hardening, coating, machining or non-destructive testing (NDT), the recycling of used solvent in built-in distillation enables a constant supply of reliably clean solvent to achieve the required technical cleanliness.

Choosing the right cleaning solution always depends on the specific context. When assessing the suitability of modified alcohols for an application, consider the following:

- What contaminations are you trying to remove (polar or non-polar)? What are their quantities?

- Are you cleaning different metal types?

- Do parts have complex geometries (such as blind holes)?

- What are the cleaning requirements? Do you have to achieve precision cleaning where exacting technical cleanliness must be fulfilled?

Apart from such technical considerations, economic factors must be carefully considered. In addition to the acquisition cost of the machine, the cost of the cleaning process should take into account, including cleaning chemistry, waste disposal costs, energy consumption, space requirements, cycle times and throughout, the potential for recycling cleaning agents, and labor costs for ensuring process stability.

Safechem | safechem.com/en/

About the Author

Richard Starkey

Richard Starkey is the Industry Manager Aviation at Safechem Europe GmbH.

Related Content

Environmentally Friendly Model 550 Versatile Parts Washer

PMTS 2023: This washer is useful in a variety of applications, including tool rooms, maintenance operations, low production and precision cleaning.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MorePMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Read MoreIndustrial Cleaning Shop Zeros In on Precision

This parts cleaning company is elevating its efforts to become a technical cleanliness expert, which presents an exciting, yet sometimes arduous, journey. The ongoing education of the team as well as significant investments in equipment and processes attribute to this shop’s success.

Read MoreRead Next

How EPA Decisions Might Affect Surface Preparation

Last year, the EPA determined that four degreasing solvents used in parts cleaning pose “unreasonable risks” to workers. By the end of 2022, there should be new rules outlining restrictions on how the solvents can be used. Solvent bans are possible. What should surface finishing companies do?

Read MoreHydrocarbon Cleaning Impresses Exhaust System Company

This Mexican company uses a hydrocarbon vapor degreasing system to clean parts it produces for exhaust aftertreatment systems for diesel engines.

Read More5 Things to Know About Replacing nPB in an Industrial Cleaning Process

Many of the nPB replacement cleaning fluids provide consistent cleaning quality, cost savings and better throughput. Plus, they have better toxicity profiles, making them safer for people and the environment.

Read More