Hard Turning and Grinding on a Single Machine

Combining multiple technologies on a single machine makes the machining process more complex, but the advantages of consistent integration of such functionality can be worth the effort.

Combining multiple technologies on a single machine makes the machining process more complex, but the advantages of consistent integration of such functionality can be worth the effort. The benefits of combining hard turning and grinding can include complete machining, improved component quality and greater flexibility. This technology combination can also be effective in reducing cycle times. Machining a part complete on one machine can drastically reduce throughput times, transport times and interim storage times. Further advantages accrue as time and effort spent in setting up the machine are also reduced.

Depending on the parts to be produced, however, implementation of such operations is not always technologically feasible. Highly complex component geometries pose certain limitations. Such workpieces often call for multiple setups, as not all the required operations can be carried out in a single setup. Furthermore, the integration of a number of machining processes (turning, milling, drilling, grinding, gear cutting) adds complexity to the machines and manufacturing systems. Therefore, it is important that particular attention is paid to the training of installation operators and setters that implement machining process combinations.

Strengths and Weaknesses

Many production environments make use of conventional external cylindrical plunge-cut grinding. Conventional grinding methods have already been optimized to a large extent and are not easily swayed by innovation. Plunge-cut grinding with CBN, however, can provide drastic reduction in cycle times when compared with the times achieved with conventional methods. The greater life expectancy of CBN tools ensures that the reduction in cycle times is accompanied by a noticeable reduction in idle times.

One disadvantage of CBN plunge-cut grinding is the high cost of the tools—the reason why the process is used almost exclusively in large batch and mass production. High-performance external cylindrical profile grinding, or peel-grinding, is a variant of CBN grinding, whereby small grinding wheels generate a workpiece profile by following an NC-controlled contour. This method, characterized by its flexibility, is ideal for the external cylindrical grinding of whole component families. The disadvantage lies in the higher capital outlay brought about by the use of high-speed technology and grinding oil.

A process that competes with grinding is hard turning. Hard turning is also a highly flexible process. According to users of this technology, its positive side is that it can also be carried out dry. However, a downside is its process integrity or the possible lack of it. Unpredictable cutting edge disintegration can lead to constant stoppages, and the component quality achieved on standard machines is limited to the IT6 range.

Combination Machine Solutions

No single method can fulfill all the demands made on hard, fine machining. Combination machines offer the opportunity to approach the question from the perspective of the workpiece and the machining requirement and come up with an optimal solution for a particular task. Optimization can then cover the three main areas of concern: productivity, component quality and production costs. Optimally equipped combination machines offer flexibility as well, as they can also be used as a dedicated grinder or a dedicated turning machine.

The design of the work spindle is influenced, to a large extent, by the demands made by the turning work. The working speed for turning is noticeably higher than that for most grinding operations. If the machine is also to be used for soft turning, the maximum main spindle torque will experience more demand than that of grinding. An important requirement is a good chip clearance. Grinding makes its own demands on the grinding spindles. External and internal machining work and the machining of shoulders make vastly different demands on speeds, drive power and rigidity. To cover the whole spectrum requires a modular spindle design.

A more general requirement for combination machines is low thermal growth. Rough turning processes, for example, can temporarily create a high, localized thermal load. The resulting thermal growth must be kept within limits to ensure that subsequent finish machining processes are not adversely affected. For combination machines to be a viable proposition, the capital outlay must be kept within a justifiable margin when compared with the investment in separate grinding and turning machines.

An example of combination machines for the manufacture of chucked components is the VSC platform from Emag. The pickup principle fulfils the demands for unhindered chip flow. Using the machine axes to load the VSC makes the process quick and simple. With its tool turrets, Y axis, B axis and grinding spindles that are firmly anchored in its base, this machine covers a range of applications.

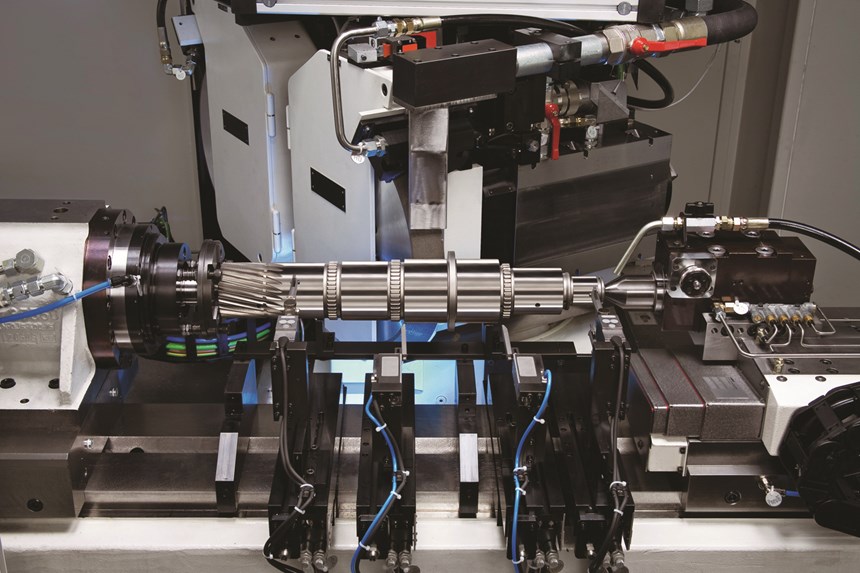

Emag’s VTC DS series is designed for combination shaft machining. Whether the goal is to turn, drill, mill, grind or turn and grind, the VTC covers all process integration variants for shaft-type components. The VTC 315 DS is for medium and large batches of high-quality workpieces such as gear shafts, rotor shafts, pump shafts, motor and engine shafts or cardan shafts. For each of these components, a suitable machining technology is chosen. Stable workpieces can be lead-free turned, whereas thin, delicate components can be ground. The VTC 315 DS can be used as a dedicated turning machine, a dedicated grinding machine or a combination of both.

Demands on Machine Design

The forces generated during hard turning call for a sturdy tool receptor. A turret equipped with live tools considerably increases machine flexibility. Unhindered chip flow is a must as well as a vital criterion of combination machining. To guarantee component quality, the wheel dressing equipment must be good enough to maintain the quality of the grinding tools that are, after all, the decisive factor in achieving quality in the machining process. To ensure that the thermal growth of the machine is kept to a minimum, the thermal growth of all relevant assemblies also must be kept under close control. Of equal importance is that the machine comes complete with effective, competitively priced automation equipment to ensure that it represents an economically viable proposition.

Proven in the Field

In the machining of chucked components, the technology combination of hard turning and grinding has become a state-of-the-art practice. However, there is still potential for further rationalization, as not nearly as many processes that could benefit from it have been converted to combination machining. In the future, turning and grinding will be joined by other technology combinations that will also include hard milling, hard reaming and honing. Shaft machining is also beginning to lend itself to process integration. One example of a suitable machine concept is the VTC 315 DS. But such systems are not yet as widely used for shaft work as they are in the machining of chucked components. Although development in this area is lagging behind by a few years, it is becoming clear that the advantages of technology combinations for the machining of shaft-type components will be explored more in the future.

Combination machining is no longer an exotic process, as both the technology and the machines have been well proven by now. The consistent application of technology combinations and the integration of other machining processes will continue to provide increased value as people realize the potential.

The advantages are obvious. Combination machines give the user the option to choose the most suitable technology for the workpieces. Of most interest now are technology combination machines for the manufacture of medium and large batches of high-quality components, with the technologies being chosen in accordance with customer demands and workpiece quality requirements, whereby stable workpieces are lead-free turned, and thinner, more delicate components are ground.

Related Content

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

Read More5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

Read MoreLaser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreRead Next

Boost Throughput With Multitasking

As a shop’s typical workload moves beyond high-production turned parts, new ways to reduce leadtimes and improve machining accuracy are evolving.

Read MoreCAM For Multitasking Operations

While still running a few different CAM systems in the shop, this manufacturer of aerospace and oil and gas industry components has implemented what it sees as the ideal package for programming its multitasking work.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)