Heads Up on Lead

The latest information on lead in precision machining workpieces and options as the supply chain becomes an issue.

It’s 2021 and now we are concerned about our ability to source the necessary leaded materials to make the critical parts our customers need. Here is the latest information on lead in our workpieces and options to keep you under control as we manage the volatility and uncertainty of the constrained supply of leaded workpiece materials in 2021.

How Lead Helps You be a Better Supplier

Lead is an ingredient in many workpiece materials in our shops. Because of its low melting point, lubricity and some other factors, lead helps us increase surface feet per minute (speeds), which reduces the cycle times to make each part. Lead additions reduce friction and, thus, tool wear, increasing uptime for our equipment as well as reducing tooling cost and reducing energy (and power) needed to make each part. The addition of lead to many of our workpiece materials results in power and cost savings on the order of 25-30% over similar but non-leaded materials.

Current Situation for Leaded Materials

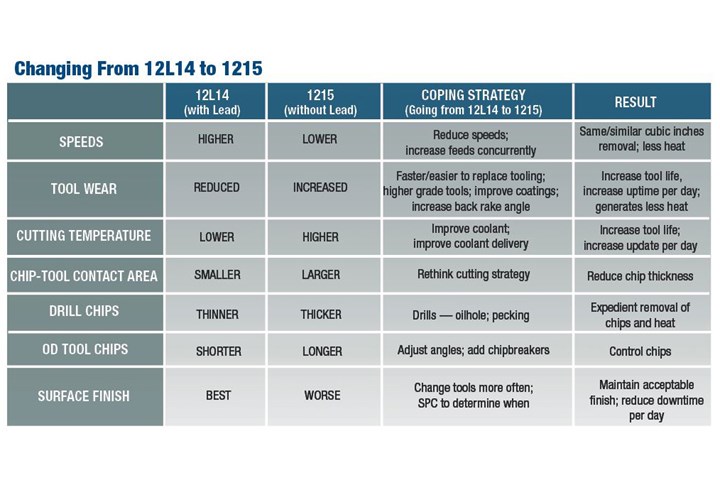

Currently, leaded materials are reported to be in short supply and, with many of these materials sourced from overseas mills, tariffs are adding to the price. Now that the economy has started to reopen, high demand for manufactured goods has resulted in very difficult times for shops trying to get the leaded materials needed to get their customers’ parts out on time. In some cases, that means a grade change to an unleaded equivalent, say, replacing 12L14 with 1215, or 360 brass with one of the new unleaded substitutes.

RoHS Annex III Exceptions Expire July 21, 2021

The existing RoHS Annex III exceptions 6(a) for steel and 6(c) for copper-based alloys expire on July 21, 2021. Link: bit.ly/PMPA-PM0521. For 6(b) 2 aluminum, the date is May 18, 2021. The expiry for 6 b and 6B -1 is also July 21, 2021. There is an ongoing consultation and review of applications to renew the existing exceptions, and remain valid until the EU commission has published its decision on the renewal applications.

- If an application for renewal is rejected by the commission or an exception is revoked, the existing exception remains in effect for at least 12 months and no later than 18 months after the date of the decision.

- If an application is approved, then, of course, the exception will continue in force as per the approval.

Despite the stated expiration date of July 21, 2021, for lead in materials for machining in Annex III of RoHS 6(a) steel, and 6(c) copper-based metals, the use of lead in these materials will continue until a final decision on their exemption has been published by the EU commission in the official journal. Even if they were to decide on July 21, 2021, to eliminate these exemptions, you and your customers would have an additional 12 months — until July 21, 2022, at the earliest, before the change in status would be enforceable.

What’s a Shop to Do?

Continuing to provide parts made from the designated leaded material on the print should be your top priority. Regardless of what is going on in the EU regulatory space, you will have a year to utilize the material. However, if you are unable to find leaded material in sufficient time to produce the products, you could try an unleaded equivalent.

Consult the reference chart on the previous page as you consider your options for moving to 1215 from 12L14 or to an unleaded brass as you move away from traditional leaded 360 grade.

Moving from Leaded to Unleaded Brass

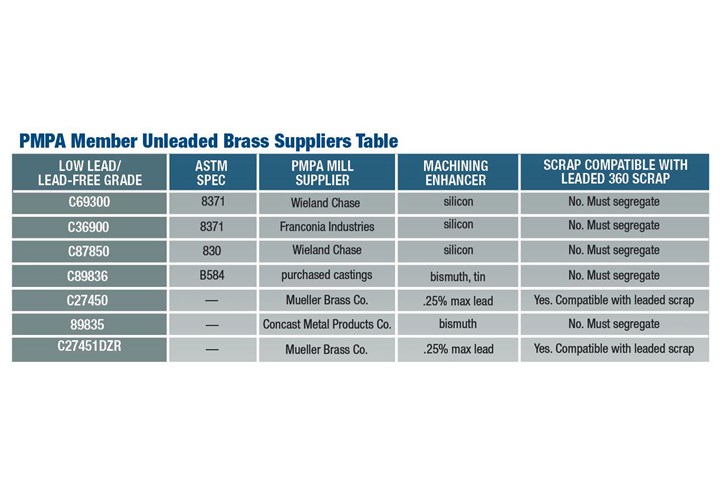

Free machining brass materials rely on the presence and absence of certain chemical ingredients to facilitate machining. The ingredients that make unleaded free machining brasses free machining are also detrimental to the production of lead-free machining brasses. Therefore, maintaining material identity and tight controls on segregating the different grades of scrap in your shop are key to assuring that the scrap materials your shop generates will be returned for highest dollar.

There is a high value of material “not used” to produce the parts: the chips, swarf and bar end remnants. Assuring that you recover the full value of your scrap materials will require you to segregate materials to avoid cross contamination and rejection, and assure materials are free of excess moisture and oil.

Failure to tend to these simple steps of material control can cost your company money needlessly, so be sure to keep scrap streams separate. Consult the chart below to find unleaded brass suppliers, the ASTM spec, the machining enhancer needed and scrap compatibility with leaded 360 scrap.

Read More Articles from PMPA:

About the Author

Miles Free III

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email – mfree@pmpa.org; website – pmpa.org

Related Content

Craftsman Cribsheet No. 128: Why Do Machinists Say Tenths Instead of Ten Thousandths?

In machinist parlance, a tenth is a tenth of a thousandth, not a tenth of an inch.

Read MorePrecision Ground Barstock: How It Is Manufactured, Benefits to Your Shop

Understanding the benefits provided by precision centerless ground barstock can help you avoid false economy and optimize the work you quote by maximizing benefits to your manufacturing process and customer.

Read MoreCraftsman Cribsheet No. 119: Defeating the Hanging Cross-Hole Burr

Deburring is a tedious task that is better left to machines.

Read MoreDo You Have a Quoting Process?

The only way to have repeatable results is to have a process.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)