How Chemistry Determines Machinability: Manganese Sulfides

The manganese and sulfur content shown on the cert determine the volume fraction of manganese sulfides in the steel.

The manganese and sulfur content shown on the cert determine the volume fraction of manganese sulfides in the steel.

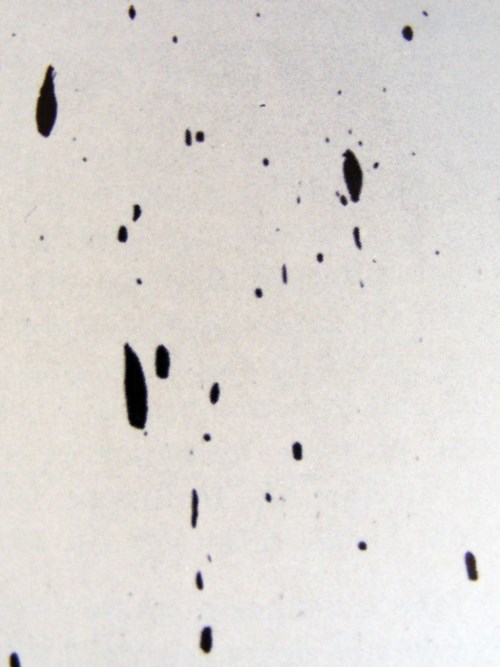

As manganese sulfides rise beyond a 1 percent volume fraction, surface finish improves, chips formed are smaller with less radius of curvature and the friction force between cutting tool and chip decreases due to lower contact area. Manganese sulfides are a separate internal phase, shown as the dark inclusion material in the photo.

How does manganese sulfide improve the machinability?

- The MnS inclusions act as stress raisers in the shear zone to initiate micro cracks that subsequently lead to fracture of the chip.

- MnS inclusions also deposit on the wear surfaces of the cutting tool as “Built Up Edge” or BUE.

- BUE reduces friction between the tool and the material being machined. This contributes to lower cutting temperatures.

- BUE mechanically separates or insulates the tool edge from contact with work material and resulting heat transfer.

This is why resulfurized steels in the 11XX and 12XX series can be cut at much higher surface footage than steels with lower manganese and sulfur contents.

.jpg;maxWidth=300;quality=90)