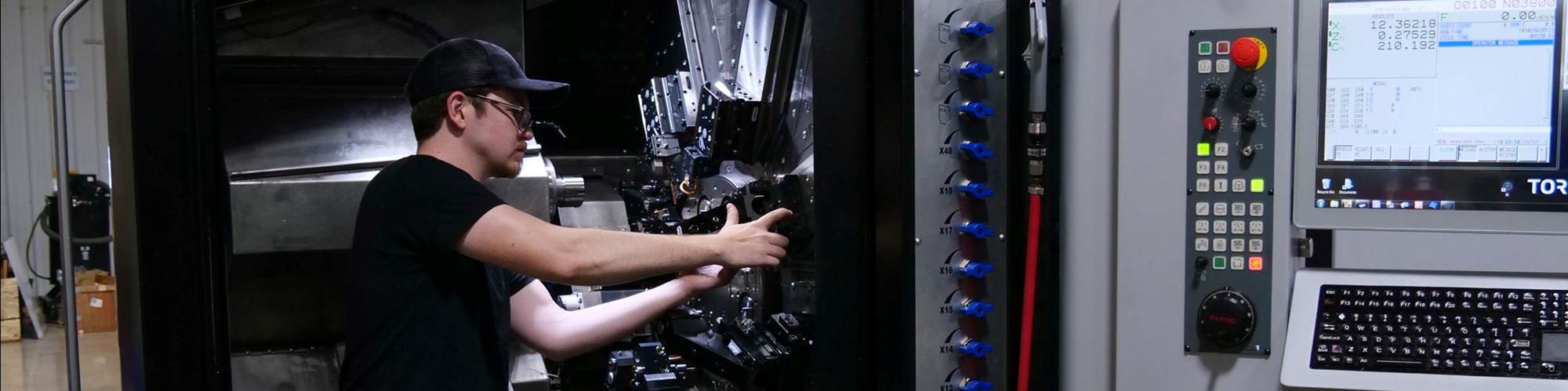

Seen at last year’s IMTS, this Artery B-axis multitasking machine from Weisser (acquired by Hardinge in 2021) has a particularly striking look. Note the subtle design elements such as the wooden door handle and trim around the CNC. These pay tribute to the machine tool builder’s location near Germany’s Black Forest. I’m not playing favorites here; I just thought it looked sleek and modern. (Photo Credit: PM)

When I started writing about machining and manufacturing some 26 years ago, CNC machining centers and lathes tended to be boxy or rectangular with enclosures having fairly sharp corners. They were certainly functional, but a bit “meh” looking. That is, at least compared to many new machine models available today.

In simplest terms, new machines often look sleek, modern and, in some cases, futuristic, with some builders hiring designers from outside our industry to assist with new designs and paint schemes.

They now more closely resemble the advanced equipment they are.

In many cases, the machine’s performance isn’t impacted one way or another. That said, I have seen designs in which new enclosures and doors offer ergonomic and safety advantages for operators. Some bar feeder brands include LED lights down their length, which not only make them more appealing to look at but also serve a practical purpose in signaling remaining bar length.

Many CNC interfaces now look much more modern, too, some resembling the same type of smart devices with which we’ve all become familiar, especially young people. Even ancillary equipment such as tool presetters and collaborative robots don’t resemble models of the past.

You’re likely not going to choose a machine simply based on its looks. The real goal is to find a reliable, well-supported machine that offers faster production, improved surface finishes and so on. However, there’s an extent to which that new equipment could be more enticing to a potential young, new hire. And, if you offer open houses, they might catch the eye of parents, teachers and even customers who might visit.

The B-axis multitasking machine above I saw at last September’s International Manufacturing Technology Show (IMTS) is a striking example. Others you might see at the Precision Machining Technology Show (PMTS) which runs April 18-20 in Cleveland, Ohio.

But, in thinking of open houses, appearances matter in all areas of your shop. For example, I’ve visited a number of shops in which the building’s façade looks nothing like a “machine shop” of years ago and the same goes for their foyers resembling that which you’d see in a nice hotel. And, while machine shops can only be so pristine, maintaining a clean, safe manufacturing environment (including machining equipment) should be part of your shop’s culture.

All this you could, and should, show off to visitors to your facility. But, also consider video in terms of a tour of your shop you could add to your YouTube channel and embed in your website/blog while pushing to it via social media channels. It’s also possible to take it a step further to enable people to take their own self-guided walk through your shop via Google street view-type tours.

In short, appearances matter. It’s important to win that first impression by a prospective new employee or customer, but also for keeping your existing personnel that’s so valuable for keeping your business engaged, positive and prideful.

Read Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)