How Should Tools Fail?

Two incidents early in my career started me on the path to learning all that I could about how tools fail. The first, at a Tier One subsidiary plant of a major domestic automaker near Rochester, was a call for immediate assistance because the cold-drawn bars that my company had supplied were causing their form tools to burn up.

Two incidents early in my career started me on the path to learning

all that I could about how tools fail. The first, at a Tier One subsidiary plant of a major domestic automaker near Rochester, was a call for immediate assistance because the cold-drawn bars that my company had supplied were causing their

form tools to burn up.

The second, at an independent company making precision parts for the heavy truck market, involved a circular form tool that had clearly been almost melted into submission. Needing to understand how these tools failed was crucial to my company’s continued success as a supplier of choice to these customers.

Tools fail. We know that they will fail. The question is, “How should they fail?” When a tool fails by an unexpected means, it is a signal that we need to adjust our process. When tools are used to machine steel, our process employs them at combinations of feed, speed and depth of cut. Tool failure modes can be a clue to which of these parameters is out of line. “Burnt up,” and “melted into submission,” however descriptive, do not give us much insight into the failure mode.

How should tools fail? In my experience, the “proper” mode for tools to fail when cutting steel is by flank wear. This is a natural response to the many inches of material being cut. It is also a steady and linear type of response, up to a point. When the flank wear starts to accelerate, it is time to change the tool. Flank wear is predictable and is the basis of almost all of the machinability tests dating back to F.W. Taylor in 1907.

Any other failure mode indicates that the cutting process is out of control. Is the speed too high? That results in too much heat. Thermal cracking, thermal deformation and rake face chipping are the likely results of too much heat. You can make adjustments to decrease speed and increase feed-to-speed ratio; in the case of rake face chipping, make adjustments to clearances. These are all steps to investigate in order to return you to the land of predictable flank wear.

Built-up edge is another failure mode that calls for adjustments to the machining process. Depending on where it occurs, the build-up could be a result of a feed that’s too heavy, clearance angles that are too shallow or material chemistry issues.

Increasing the speed-to-feed ratio, and/or increasing clearance angles are two parameters you can control to minimize this condition.

Cratering is a failure mode that is related to speed (high heat) in combination with pressure from the chip. Besides decreasing speed, upgrading tool base material is the way that this failure mode is typically solved.

Other specialists will be able to tell you many different methods you can use to eliminate these failure modes, from different coolant or cutting oils to different coatings on the tools to different tool materials and geometries. All of these solutions might be available to give you an ideal means for making your part. First, you need to know what is normal in the way of tools failing.

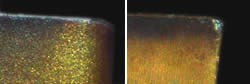

How did I solve my first two tooling failure incidents? The first—at more than $1,000 for same-day airfare and car rental expense—was a no-brainer. The form tool was cratering on its side, not the flank or rake surfaces.

In fact, the cratering—that looked like a stepped valley surrounded by hot lava—was caused by the tools’ angular approach into the collets of the multi-spindle automatic.

Some “professional” had obviously had a wreck on a midnight turn and nobody recorded it. The day shift was unable to interpret the tools’ own visible testimony. Their observation was, “You’re right, the tool is worn into the same shape as the nose of our collets.” So, they did the easy thing and blamed the steel supplier.

The second incident involved similarly abused tools that showed wear, cratering and evidence of very high heat, as well as documented evidence of rapid wear. Production records showed the tools were failing in a fraction of the usual time.

No process issues could be discovered, but a check of the steel’s chemistry showed it to have substantially lower sulfur than prior heats supplied. A return to a steel with a higher sulfur level made the tools’ premature mixed mode failure issue go away.

Knowing how tools fail, and how they are supposed to fail, is a critical competency for each of us in the precision machined products industry. After all, our business is the application of tools to material to create products. It is when we can recognize the difference between how our tools are failing and how they should be failing that will help us get our processes back into a more predictable and stable condition.

How should tools fail? How are my tools failing? Our goal is to work to better understand our processes. This task lies in the gap between these two simple questions.

Read Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More