How To Automate Your Shop

A fully integrated shop management system will help attract new customers, deal with constant change and manufacture more cost effectively.

Today's screw machine shops face overwhelming challenges—endlessly changing requirements within the shop, the business and the economy make it difficult to attract sufficient business, provide top-notch service and fully utilize the shop's assets. One of the key ways to meet these challenges is through the use of technology. Implementing a fully integrated shop management system can provide the solutions needed.

Automating the information process and connecting the office with the shop floor via a robust, fully integrated Windows-based enterprise resource planning (ERP) system will help you gain control and streamline your business. Current ERP systems run on Microsoft NT networks and connect your shop and customers like never before. They also provide efficiencies necessary to create a lean manufacturing environment. The key is to find a fully integrated system that fits your shop flow and will carry you into the coming decade and beyond.

Evaluating Your Shop

Why do you need to automate? Why do you want to automate? Why haven't you done it until now? What do you want out of an ERP system? Before you evaluate software, reevaluate your internal processes. Is the "we've always done it this way" thinking getting in the way of strategies for the future? Also, be sure to analyze your shop's current information process before you try to automate. Consider the following:

1. What happens during the information system process? Chart a flow of your current information system from the time you quote a part until your customer receives the part.

2. What information are you duplicating in this process?

3. What information are you not gathering and analyzing now that you would like to have when you automate?

4. What information are you gathering and analyzing through various methods that must be in an automated system?

Make a prioritized list of the capabilities and features you would like your new system to have. Stay focused on the "meat and potatoes"—your everyday activities. Then create your wish list.

Types Of Manufacturing Systems

When you automate your shop, you gain a central database that can be accessed by all employees. This eliminates duplication of information, allows employees to make decisions based on facts, and streamlines information procedures. Security levels can be set up within different aspects of the software, as needed.

Before looking at specific ERP systems, make sure you know what type of system you should be considering. The two basic types of manufacturing software are item-based and job-based.

Item-Based. This type of system was introduced several years ago as material requirements planning (MRP/MRPII). It is designed for a manufacturer making standard products. The inventory item or part item is the main master file. A sales order reduces inventory and, as a separate step, a work order is generated to replenish inventory. These systems help with forecasting, and the product is shipped from finished goods.

Job-Based. Job-based software is designed for manufacturers making parts to customer specifications—such as most screw machine shops. These systems concentrate on actual labor, material and outside service costs. They typically are designed around shops that deal with a lot of change. They also have the ability to track inventory.

The remainder of this article focuses on the functionality within job-based ERP systems—the software most made-to-order screw machine shops will need. A truly flexible, fully integrated system will emphasize quoting, material management, scheduling and costing.

Quoting

Automating the estimating process can help you save time and improve accuracy. Make sure the system you're considering can handle the following:

- Develop your quote by entering into the software the quantities; manufacturing steps with estimated setup and run times; material requirements with estimated costs or inventory requirements; outside processing; and tooling.

- Using this information and hourly rates, markups and inventory costs, the system automatically calculates the pricing for each quantity.

- For repeat quotes, you should have the ability to use part history to generate a new quote for the same or similar parts. An estimate can be retrieved by part number or by part description. With a quote history, you can also analyze hit rate and produce reports for quote management and follow up.

- E-mail or fax the quote from the system. Employees will have visibility into the system and can easily respond to customer inquiries.

Automating your quoting process is like throwing a long pass for a touchdown—it yields a quick return. How efficiently you quote and how well you follow up has a direct effect on the amount of business you bring in annually.

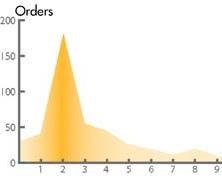

Quick turnaround and follow up on quoting can generate a major increase in business within the first year. Let's say it enables you to do five more quotes a day or 25 more a week. If those additional quotes result in just one more order per week—with the average size order being $3,000—that's $150,000 of incremental business annually.

With a job-based system, you can copy the quote information from an estimating file over to the order file without re-entering the information. For repeat jobs, you can retrieve the file from the last time the part was made and copy that information to a new job.

Automated order entry systems provide automatic updating of shop floor reports such as scheduling and costing. They also allow you to automatically generate your shop traveler. Most systems allow unlimited notes and comments. The system must be able to handle unlimited text on the shop traveler for quality control information as well as work instructions for the shop.

Material Management: Integration Is Key

Material requirements tie right into an automated order entry system. Make sure inventory requirements are automatically allocated to jobs and direct purchase items are flagged in purchasing as order requirements for a specific job.

Raw material stocking levels should be online, as should be the status of purchase order requirements. On most systems, purchase orders can be automatically created, directly emailed and/or printed for materials required by jobs, for inventory subcontract services, and for miscellaneous shop needs.

Constant order changes (order quantity, material, delivery schedules) make scheduling extremely difficult in a screw machine shop. That's why total integration of the job's requirements is crucial for streamlining the process of scheduling. This means all material requirements purchased for jobs or pulled from inventory and subcontracted services and subassemblies are integrated or automatically linked with the job's routing.

When the job's schedule changes, the requirement dates for all dependent activities automatically change. If any of the dependencies are not going to occur when needed to ship on time, an exception red flag or similar device lights up within the system's Exception Report.

Scheduling

Depending on the way your shop prefers to schedule jobs, one or more of the following will be the option you choose. All should be available within your new ERP system.

Infinite scheduling allows you to maximize work center usage and manually distribute workload among them. It adds an individual's job schedule to the current workload, regardless of the current shop load, and it shows when areas in the shop are overloaded and by how many hours. You can then move various jobs around in the system or schedule overtime to accommodate the workload.

Finite scheduling allows scheduling only to the point defined as 100 percent capacity. Since it will not over-schedule, it might push some jobs out beyond their due dates. To prevent this, you can use job priority codes, requested ship dates, priority start dates, and remaining hours as the criteria, in any order you choose, when running a finite schedule. The system "shuffles" your jobs to use your work centers efficiently.

Global infinite scheduling is a combination of infinite and finite with a focus on making delivery dates. In made-to-order manufacturing, routings for each job or part tend to be unique and often unpredictable. Global infinite scheduling gives you the option of globally rescheduling your shop with primary emphasis on delivery dates and capacity planning.

A graphical scheduling board is a popular option for many shops. An example is a visual white board, such as ShopBoss from Kewill ERP (Minneapolis, Minnesota). This portion of the system is a graphical scheduling board that lets you visualize the related material and outside services as you manipulate schedules, do what-if scenarios, and change jobs around on the fly.

Most systems offer exception reporting to show you which jobs were pushed out, so you can decide what to do with jobs that will not be completed on time. In general, though, automated scheduling systems will help you coordinate the shop schedule with delivery dates to help you ship on time.

Job Status And Costing

If a customer calls about job status or job changes, you need to supply the answer immediately with online, real-time job status reporting. Many systems now offer reports and status information directly to your customers via the Internet. One example is the Kewill View for JobBoss package, a web-based customer service tool that provides your customers with accurate, timely job status and production information 24 hours a day. It reduces customer calls to check on jobs and also improves customer relationships.

Cost reporting will give you the information to analyze shop performance. With automation, cost data is available while a job is still in progress, allowing you to compare estimates and actuals. If a job is costing more than anticipated, an exception report will show cost overruns. In addition, rework and scrap can be tracked by employee and by job.

Make sure you can also check work-in-process (WIP) costs, track your projected revenue, and analyze part histories. Because in many cases you deal with repetitive parts, your system should definitely provide part history reporting.

Data Collection To Drive The System

Good shopfloor reporting depends on employee job time entries to drive the system. When employee time is entered, the system automatically updates job status, scheduling/shop loading, job costing and efficiency reporting.

Employee time can be collected using PCs, data collection terminals or hand-held devices. Employees simply scan bar codes on shop travelers as they work on jobs. These bar codes include employee number, job number and operation number.

This recommended method offers real time status and automatically handles material and time transactions for an up-to-the-minute picture of your shop. Real time data collection systems offer a variety of transactions such as inventory, purchase order receiving and so on.

Completing The Cycle Of Integration

Delivery and backlog reporting are automatic in a fully integrated ERP system. Most systems should allow you to ship from stock and from jobs—auto-matically reducing your inventories. Packing lists are generated, and shipment history is tracked. In addition, reporting tracks your delivery performance by customer.

Make sure your new ERP system offers tightly integrated accounting, which automatically generates an invoice upon shipment of a job, integrates accounts payable and accounts receivable, and then updates information to the general ledger.

A totally integrated system should also allow you to tie in with Microsoft products and communicate, analyze, graph or e-mail your data just about any way you want using Microsoft Office. Make sure you can import and manipulate data within Word or Excel and e-mail reports internally and to customers, eliminating the need to print them out.

Custom reporting should also be available, allowing you to define and create reports to look and work the way you want. You'll also need the option of customizing your forms such as travelers, quotes, order acknowledgments, purchase orders and shipping labels.

The Benefits—Working Lean

Once you select software, plan on a 3- to 6-month implementation. From the start, your system will begin to create major efficiencies. As it applies to a screw machine shop, lean means operating with tighter shop management: marketing your business by quoting a larger number of jobs within a tight time frame; the ability to shorten lead times from quote to order; and tighter throughput from quote to invoice.

Lean also implies constantly working to reduce WIP. The longer jobs take, the more jobs you have in house and the more work in process you're carrying, which ties up cash flow. Robust job control for balancing the workflow will lead to a reduction in WIP and better utilization of assets.

Lean manufacturers produce only what's needed at the time, improving cash flow dramatically.

Manufacturing lean has become a matter of survival in today's business climate. If the current recession is affecting your shop, plan to automate now while your workload is lighter. Begin turning your business into the new breed of screw machine shop— tightly managed, lean and highly profitable.

Related Content

MachineMetrics Automates Robot Performance Monitoring, Intelligence

Precision manufacturers can now monitor collaborative robots from Universal Robots in real-time to drive automation that improves performance and reliability.

Read MoreProShop Provides ERP Technology to Purdue Engineering School

The ProShop Digital Ecosystem will be used as the inventory management and ERP system at Purdue University’s Industrial Engineering School.

Read More10 Ways AI Might Impact Manufacturers

Artificial intelligence offers the promise of assisting decision-making processes and boost overall manufacturing efficiency.

Read MorePrecision Machining Technology Review: November 2024

Production Machining’s November 2024 technology showcase includes some of the latest technology from Vericut, Hurco, the L.S. Starrett Co., LNS North America, Fryer Machine Systems and MachineMetrics.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)