How to Get More Efficient Production from Swiss-Type and Multitasking Machines

Sponsored ContentSolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

Share

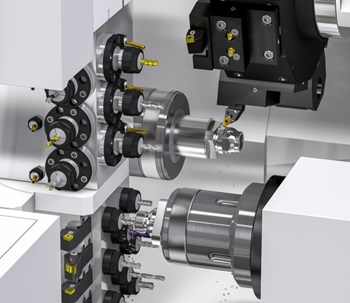

A big trend in recent years has been the rapid adoption of Mill-Turn equipment such as multi-axis Swiss type turning centers larger multitasking turning centers. With the “done-in-one” approach, very complex parts can be produced in a single setup. But many shops are underutilizing their turn-mill centers because they can be difficult to program, and CAM systems have been slow to support advanced milling techniques on this type of equipment. This forces shops to run higher lot-quantity jobs on their expensive Swiss and multitasking turning centers inefficiently, with longer than necessary cycle times.

WATCH: SolidCAM high performance turn-mill for Swiss and multitasking turning centers in action.

CAM developer SolidCAM has an answer for this with its intelligent iMachining toolpath generator, driving and protecting even the smallest cutting tools effectively, on these advanced Mill-Turn and Swiss-type CNC machines. The CAM system combines advanced multitasking programing functionality, integrated channel-synchronized simulation, and state-of-art milling capabilities, all integrated into a 3D CAD modeling platform. This enables shops to generate production-ready CNC part programs with reduced cycle times much faster and more easily via better management of simultaneous turning and milling operations and more efficient milling routines.

Dr. Emil Somekh, the Founder and CEO of SolidCAM, emphasizes that one of the important benefits that SolidCAM provides its users is the ability to run inside the popular CAD systems SOLIDWORKS and Autodesk Inventor. This gives shops no-compromise 3D modeling capabilities while eliminating all CAD-to CAM file transfer issues which are present when working with standalone CAD and CAM systems. You can work back and forth between design iterations and creating toolpaths, with full associativity of the toolpath to the updated design model.

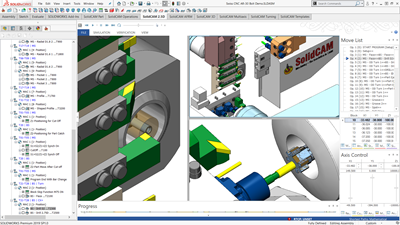

SolidCAM Simulation brings your Mill-Turn to life.

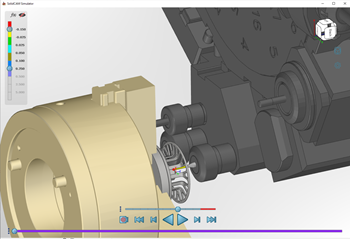

This no-compromise philosophy becomes even more apparent in the CAM part programming process. With many CAM systems, programmers must build a multitasking program operation by operation, and then wait to see a full simulation on another application. With SolidCAM, simulation is completely integrated within the part programming process. The ability to fully visualize a turn-mill machine preview at each step of the part programming process is a faster, safer, and more effective way to generate validated CNC code. SolidCAM also takes the simulation to the next level by simulating synchronized channels throughout the turn-mill process. This enables programmers to balance simultaneous operations more easily, generating efficient part programs, avoiding collisions, and ultimately generating a ‘first-part’ perfect output. The net result of all this is to generate safe and efficient CNC programs, for even the most complex parts, in the shortest possible time.

WATCH: SolidCAM user machines medical device on Star CNC Swiss turning center.

State-of-the Art Milling Comes to Multitasking Turn-Mill Machines

As progressively more complex milling is being done on what were once thought of as turning centers, the ability to execute those milling operations efficiently grows more important by the day. Multitasking turn-mill centers machines are expensive, and they typically don’t have a large cutting tool capacity. To get the most out of their investment, shops need the ability to compress machining time, yet extend cutting tool life as much as possible, and that’s what iMachining does. Dr. Emil Somekh attests to the fact it can reduce machining time by 70% or more AND increase tool life by as much as 5 times or more. That’s a big claim, so let’s examine how it works.

Multiple Channels of Advanced Mill-Turn on a QuickTECH CNC.

iMachining employs advanced high efficiency milling to reduce cycle times, using solid end mills, small stepovers, faster feed rates and deeper axial depths of cut. The key to achieving the highest possible metal removal rates is to generate optimized morphed spiral tool paths, with variable cutting angles (radial tool engagement) and feed rates at every point of the toolpath, so that there is a constant spindle load. This avoids the shocks that occur when material engagement changes abruptly, for example, when a cutting tool hits the corner of a pocket. Without this capability, you must manage feed rates for the worst-case cutter load scenarios, making cycle times much longer than necessary. Moreover, maintaining a constant spindle load substantially reduces vibration, thus yielding dramatic increases in tool life as well as better surface finishes.

This capability is particularly useful on CNC Swiss turn-mill centers when milling with small diameter tools. SolidCAM has customers who routinely use 0.015” diameter endmills at the full depth of cut and even smaller tools can be accommodated based on the way that iMachining controls the engagement angle (radial DOC).

SolidCAM is used on and has post processors for all popular Swiss-type turning centers including Citizen, Star, Tsugami, Miyano, Ganesh, Quicktech and Nexturn.

Equally important for Swiss and many other multitasking machines, SolidCAM includes Virtual Machine ID (VMID) which enables part programs to be tailored to a specific machine. This allows users to define electromechanical elements of the machine such as maximum spindle horsepower, speed and feed rates. This enables the generation optimum milling routines regardless of how fast or powerful a milling spindle may be.

How to Achieve Maximum Tool Life

iMachining has been shown to not only generate better Material Removal Rates (MRR) than any other toolpath technology, but also amazing increases in tool life. Many people might assume that since iMachining is more aggressive with metal cutting speeds and feeds, that it should wear out the cutting tool sooner. So how is it that iMachining provides much better tool life?

WATCH: SolidCAM's patented iMachining for Mill-Turn centers provides maximum material removal rate and longer tool life.

To understand this, we must first understand solid carbide cutters. Carbide is an extremely hard material; it can stand up to compressive forces beyond most other materials and it is also highly resistant to abrasives. These factors make it a great material to use for cutting tools used for machining steel, super alloys, and most other metals. But along with being extremely hard, carbide is also very "brittle" – it will not stand up to tensile force (bending force) very well at all.

iMachining ensures that the carbide substrate at the sharp edge of the solid carbide tool flute never sees tensile force - it only sees compressive force. Therefore, the sharp edge resists micro chipping, even at elevated performance levels as seen with iMachining, resulting in dramatic improvements to tool life.

One other large factor in increasing tool life is the ability to run cutting tools at their full depth of cut. In the past, in order to avoid putting too much stress on brittle tools, CNC programming systems would only generate shallow cuts to compensate for over engagement. With iMachining, making use of the full cutting depth of the tool it never over stresses it and actually spreads the forces out over a greater area, further maximizing tool life by using the full length of the flute instead of just the bottom 10%.

WATCH: SolidCAM's powerful Advanced Mill-Turn and Swiss-Type solution.

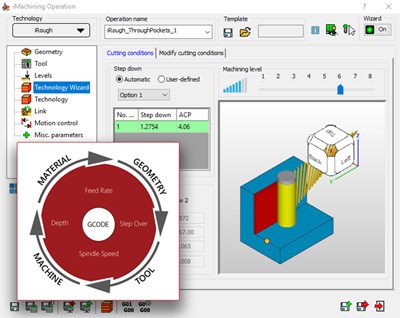

iMachining Technology Wizard

With SolidCAM's iMachining Technology Wizard you choose your level of aggressiveness and the Wizard does the rest.

Since SolidCAM’s iMachining Wizard uniquely and automatically calculates optimal feeds and speeds, taking into account the cutting tool, stock material and machine characteristics, this assures ‘first-part’ success, without time consuming, extensive trial and error to determine optimal cutting parameters. The iMachining Technology Wizard removes practically all of the guesswork involved with setting the machining parameters.

iMachining has the intelligence built in to ensure the most efficient milling toolpath for every part geometry feature in both 2D and 3D iMachining. iMachining 2D handles the roughing, semi-finish, and finish of prismatic parts. iMachining 3D replaces multiple standard roughing and semi-finish operations of complex 3D shapes with a single-click, high-efficiency process. The programming time savings are stunning.

For twin-spindle turning machines, the Machine Control Operation (MCO) function takes the worry out of synchronizing part transfers between spindles and pick offs. Programmers just enter the necessary parameters and SolidCAM does the rest.

With all the automation in iMachining, the only adjustment most users make is with the iMachining level slider that controls how aggressive the operator wants the machine to remove the material. “Imagine putting the knowledge and experience of hundreds of CAM and CNC masters in the palm of your hand. Experience the iMachining Wizard and Tool Path!” says Dr. Somekh.

Advanced Tool Table for Multitasking and Swiss Turning Centers

SolidCAM’s new advanced tool table enables intelligent managing of the tool posts, with predefined tool assemblies. Multi-body tool components provide precise collision detection and flexible tool assembly changes. Special functionality for Swiss type turning centers enables direct entering of tool setup values to SolidCAM. Angle head attachments with rotary axes can be directly managed from the tool table.

The support of any kind of 3D cutters, including the micro turning tools, enables the user to have precise collision control.

Multi-Channel Synchronization

The SolidCAM Mill Turn and Swiss advanced Multi-Channel Synchronization specializes in factoring in the CNC machine kinematic limitations, and the controller limitations, when doing the synchronization of parallel multiple tasks. All the extensive info about the CNC machine, including the above-mentioned limitations, are defined in the Virtual Machine ID, which is the Digital Twin of the actual CNC machine. The intermediate simulations perfectly reflect the results of the Multi-Channel Synchronization.

WATCH: SolidCAM's entire process from CAM to cutting on a CNC Citizen Swiss turn-mill center.

The user interface of the SolidCAM channel synchronization has dual modes: the first is a time-based Gant-like picture that gives the overall timing of the piece. The second is operation-based, giving the user the complete picture of the operations after synchronization. Seeing both output modes gives the user a very clear understanding of the synchronization execution.

SolidCAM's simulation lets you visualize your CAM programming through every step of the process.

The Swiss solution automatically activates machine kinematics superimposition and master-slave axes modes, eliminating the need for the user to manually activate these modes. Smart logical crash detection, clearly showing the problem to the user, assists in executing necessary synchronization changes to solve a problem, long before any machine is compromised.

According to Shaun Mymudes, SolidCAM, Inc’s COO: “A major factor in the successful implementation of SolidCAM’s solution is the advanced technical and postprocessor support of our experienced team.” Summing up, SolidCAM for multi-axis Swiss type and Mill-Turn multitasking machines brings together multiple technology advancements, to optimize the whole process of CAM programming of these complex machines.

For more information, please visit at SolidCAM.com and forum.SolidCAM.com.