Implementing Wiper Inserts to Maximize Productivity

This article looks at how wiper technology improves surface finish in turning operations.

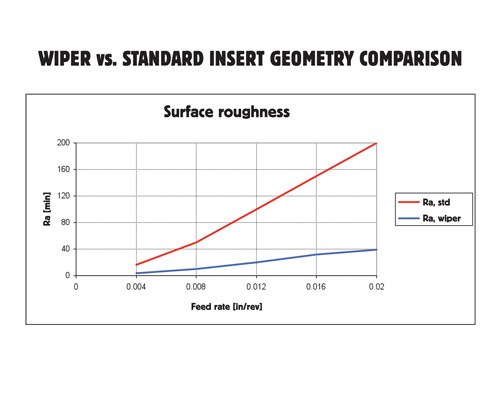

Surface finish in turning operations depends on a variety of factors. Feed rate and the size of an insert’s nose radius are considered to be the most influential of these. The traditional understanding has been that Ra increases with increased feed rate and decreases with a larger nose radius.

This has become less absolute in recent years, with the introduction of wiper inserts designed for high feed finishing. The unique geometries of these inserts reduce the trade off between surface quality and feed rates, allowing for highly productive machining of fine surface finishes.

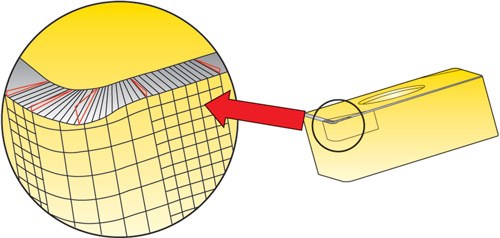

In essence, wiper inserts can be thought of as combining elements of round and rhomboid geometries to provide high performance at specific cutting edge angles. A special grind is performed on the nose radius, creating a geometry that wipes away the miniscule peaks and valleys found on a material’s surface.

Typically, implementation of wiper geometries allows for feed rates of 300 percent of what could be attained with standard inserts, while achieving the same level of surface finish. Alternatively, integrating wiper geometry and maintaining the same feed rate will result in much higher quality of surface finish.

These unique inserts have evolved substantially as cutting tool providers have invested heavily in research and development to improve their performance and broaden their applicability. Some manufacturers who tried the technology several years ago and were disappointed would be well served to reevaluate the potential benefit it can now provide.

A major consideration to take into account when looking at wiper inserts should be the geometry of the part being machined. If there is any sort of contouring, no benefit is likely to be gained. For straight turning operations involving facing or ID or OD turning, the potential for significant process improvement exists.

Additionally, the rigidity of the overall setup should be evaluated. A new turning center equipped with high quality toolholding and workholding should have no problems enabling the benefits of wiper inserts. On the other hand, older machines with less rigid setups may struggle to provide the level of performance required by these geometries.

Manufacturers should also remain mindful of the nature of the benefits provided by wiper inserts. Depending on implementation, the results can range from greatly increased productivity to a much higher quality of surface finish.

For many companies, the greatest benefit will come from increasing feed rates to minimize process time. Some, though, may actually find it preferential to decrease feed rates and raise the level of surface finish well beyond what could be achieved with a standard insert.

With the ability to achieve a surface finish of 5 Ra at a 0.004 ipr feed rate, wiper inserts can eliminate the need for grinding with some components. Those able to do away with this secondary operation will usually find it well worth slowing feed rates and increase the process time of their turning operations.

While standard wiper geometries have been on the market for several years, the industry is now starting to see positive and negative angle variations of the technology. A positive wiper allows for the same benefits, but with less tool pressure. This proves extremely beneficial to processes that could have benefited substantially from the higher performance of wiper inserts, but were taking place on setups that lacked the rigidity to handle the extra pressure generated by a flat wiper radius.

Alternatively, negative wipers actually increase the tool pressure generated during cutting. While this could be unacceptable for some applications, those manufacturers with highly rigid machines, workholding and toolholders can experience a tremendous benefit. The negative angle ground onto this style of wiper causes crater wear to occur further from the cutting edge, resulting in all of the benefits of a standard wiper, but with much longer insert life.

While the new positive and negative wiper inserts have only been on the market for a relatively short time, they have already provided substantial results for some manufacturers. A precision manufacturer of small components for the aerospace industry located in Michigan had attempted to integrate wiper inserts in the past.

Unfortunately, traditional flat geometry wipers could not be used on this application because of the high tool pressure generated. As a result, the company was using a standard insert running at a very low feed rate.

However, upon the release of positive angle geometries, another attempt was made to implement the technology. With the lower tool pressure, the new insert was able to be used, allowing the company to increase feed rates by a factor of four. This resulted in documented annual cost savings of more than $800,000.

While wiper inserts still tend to do best with a specific type of application, recent breakthroughs in edge geometries have substantially broadened the technology’s range of applicability. Manufacturers performing finishing operations with straight turning would be well served to contact their cutting tool provider to learn more about the potential benefits to their operations.

— Seco Tools LLC

Related Content

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read More4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)