Improved Indexable Insert Stability

Sandvik Coromant will introduce its iLock at the September EMO exposition in Germany as a way of improving indexable insert stablility when cutting metal.

To achieve increasingly tight tolerance demands, shops are looking for better ways to consistently cut metal. Reaching a level of stable machining is often a process of elimination, taking one factor at a time to meet tougher dimensional and surface finish specifications.

Progressively, measures to reduce or eliminate instability have focused on larger issues, such as the machine tool, fixturing, toolholding, tool design, insert geometry, tool path and cutter overhang. As these variables are brought under control, the search then continues for other sources of instability.

One such variable is the insert toolholder interface. The traditional three-point interface used by most cutting tools has been the main solution in supporting insert sides from being moved by cutting forces. For many operations, this system is still a viable means of securing an indexable insert.

However, some operations make greater demands on insert stability than others including bi-directional profiling, high-speed milling and threading, to name a few. These operations create higher cutting forces that act radially on the insert cutting edge, which in effect, try to wrest it from the three-point interface.

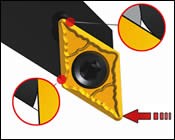

This tendency for micro-movement is especially acute in long, narrow inserts such as “V” and “D” styles. Profiling operations using these long, pointed inserts usually involve varying depths of cuts and feed directions.

Variable cutting forces act a relatively long distance from the insert seat and hold-down screw. This creates a long-lever effect, which can force the cutting edge slightly out of position. Moreover, wear and minute insert variances accentuate these micro-

movements, resulting in over-cutting or undercutting of a finish dimension and/or more frequent tool-comp adjustments.

On a recent visit to Sandvik headquarters in Sandviken, Sweden, we were shown a new system for securing these problematic indexable inserts in the toolholder. The company gave us a sneak preview of this new system, which is scheduled to be unveiled at the September EMO exposition in Germany.

Only recently have inspection systems become fine enough to detect these small movements of seated inserts. Until now, this effect has been largely unrecognized and accepted as part of the process.

Armed with data identifying insert instability issues, Sandvik’s researchers developed a new system that eliminates micro-movement in stressful cutting operations. The result is a new system called iLock.

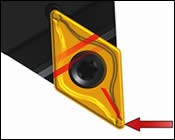

Unlike traditional three-point seats that secure the insert on its sides and bottom, Sandvik’s new system uses a T-rail design to support the insert axially and radially. It works much the way a V-block does in that the mating surfaces are self-centering. Also, because of the axial and radial location of the rails, the insert is secure for high cutting-load turning. The rails are machined in the toolholder, and a mating set of grooves is pressed in the insert.

With this system, the insert rests on the rail slightly above the toolholder land area. The screw is only used for securing the insert; it does not contribute to the positioning of the insert as in a conventional, three-point system. The screw is not affected by cutting forces, which are channeled into the T-bar and through the toolholder to the machine tool.

As shops continue to eliminate process variability to achieve consistent dimensional and surface finish requirements, improvements in previously unrecognized inconsistencies will help move the manufacturing of precision parts forward. The metalcutting process is a system dependent on variables that must be in harmony to create optimum results. Each potentially negative variable that can be identified and remedied moves the industry closer to perfection.

Related Content

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreTungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreCoolant-Through System, Toolholders for Improved Efficiencies

Eastec 2023: The reCool retrofittable reCool coolant-through system converts existing flood-cooled driven tools on turning machines to through-tool, coolant-capable in as little as two minutes, while the powRgrip high-precision toolholding system is said to generate extremely high clamping forces equal to or higher than shrink-fit holders.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.png;maxWidth=300;quality=90)