Improved Waste Stream Processing is a Pathway to Savings and Compliance

In metalworking, addressing two specific aspects of waste stream management — wastewater and spent cutting fluids — can help companies not only meet environmental compliance, but also reduce expenses.

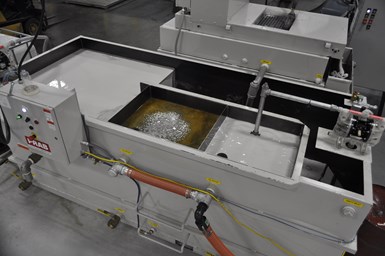

Coolant recycling lowers hazardous waste storage, haul-away liabilities and disposal costs. (Photo credit: Prab)

Higher civil penalties for environmental compliance lapses are here. Fortunately, there are ways for companies to reduce their compliance-related financial risk and lower their operating costs in the process.

Under the provisions of the Federal Civil Penalties Inflation Adjustment Act Improvements Act of 2015, various government agencies, including the U.S. Environmental Protection Agency (EPA) and those within the Department of Labor, are required to adjust their civil penalties annually based on the previous year’s rate of inflation. As a result, civil penalties for violations saw a sharp rise of 7.7% in January 2023 compared to the previous year.

Even before this year’s increase, however, manufacturing companies found themselves facing significant fines for EPA violations.

In 2022, an Indiana oil processing facility faced a hefty $310,000 settlement for violating the Clean Air Act. Similarly, an Iowa hydraulics manufacturer incurred a $26,534 fine for hazardous waste violations under the Resource Conservation and Recovery Act (RCRA). Furthermore, a Massachusetts manufacturer of power systems and controls was fined more than $120,000 for failing to meet the requirements necessary to operate as a “large quantity generator” of hazardous waste. In 2021, an Iowa-based manufacturer of truck equipment was also penalized $50,208 due to “large quantity generator” RCRA violations.

In metalworking, addressing two specific aspects of waste stream management — wastewater and spent cutting fluids — can help companies not only meet environmental compliance, but also reduce expenses.

To mitigate wastewater liabilities, several processes can be used — often in combination — to lower financial risk and achieve zero liquid discharge goals. Ultrafiltration, for example, produces a consistent and quality effluent by separating organics, emulsified oils and suspended solids from wastewater. This enables the treated water to be reused or disposed of.

Another key process, tramp oil separation, removes free-floating and mechanically dispersed tramp oils, bacteria, slime and inverted emulsions. These contaminants are often found in machining and grinding fluids, wash waters, cooling water and wastewater.

Reverse osmosis is often used as a secondary treatment after ultrafiltration to remove dissolved salts, as well as colloidal and suspended matter. The concentrate can be either sent to the Publicly Owned Treatment Works or processed more on-site to further reduce the wastewater volume.

Vacuum filtration and vacuum evaporation are also used in certain wastewater applications. Vacuum filtration eliminates high levels of contamination by removing fine particulate and collecting solids and sludge. Vacuum evaporation significantly reduces process water and wastewater volumes. The distillate produced from vacuum evaporation can be reused in the process, while the concentrated waste can be hauled away.

Two popular methods for lowering hazardous waste liabilities associated with cutting fluids are wringing chips and recycling the coolant. During wringing, centrifugal force spins metal chips and drains cutting fluids for reclamation.

A centralized coolant recycling system takes that one step further by removing tramp oils and suspended solids from contaminated fluids. This process controls bacteria to significantly extend coolant life so that it may be reused. For example, Prab Guardian systems can also adjust fluid concentration. Because the cutting fluid is being recycled and reused, hazardous waste storage, haul-away liabilities and disposal costs will all be lower.

Stricter environmental regulations are inevitable, but that doesn’t automatically mean that environmental compliance has to be a drain on the operation. With the assistance of a total solutions provider of process water, wastewater and fluid management equipment, metalworking companies can not only reduce their liability risk, but they can also lower their operating expenses. In this way, environmental compliance is a pathway to cost optimization as much as it is a regulatory responsibility.

About the Author

Tom Tripepi

Tom Tripepi is the fluid filtration technical director at Prab, a designer and manufacturer of process and wastewater systems, as well as engineered conveyors and equipment for processing turnings, chips and metalworking fluids. Tripepi has decades of experience in cutting fluid and wastewater filtration.

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)