Metal turning shredders, bundle breakers, rolling-ring crushers and hammer mills and horizontal- and vertical-axis crushers seem to achieve the same basic output. That is, they modify metal scrap to create smaller, flowable chips and reduce overall scrap volume. So, what are the unique benefits and limitations of these individual components?

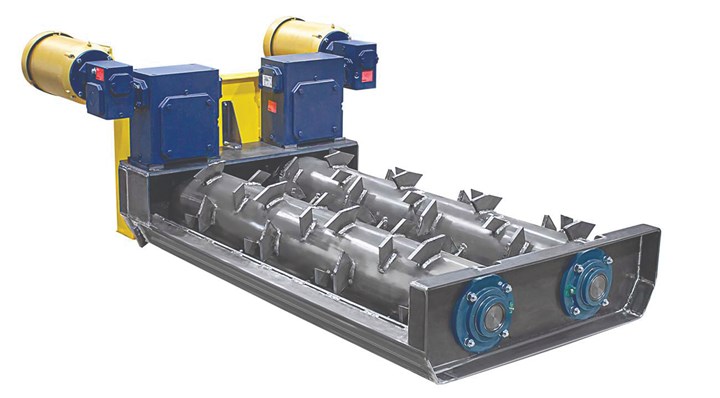

Let’s first consider the grouping of shredders, horizontal-axis crushers and bundle breakers, which have one thing in common: they modify low-volume quantities of metal turnings to create flowable chips that are ready for additional downstream processing.

Machine shops have many options when it comes to handling chips. (Photo credit: PM)

And while all those systems achieve the same outcome, they each do it differently. Shredders shear the material. Bundle breakers tear the material apart. Horizontal axis crushers rip and grind the material until flowable chips are produced. This reduction is necessary not only to protect the downstream equipment during further processing, but also to promote consistent and efficient results.

Bundle breakers modify bushy wads of metal scrap so that augers and steel belt conveyors can successfully transfer material that would otherwise bounce around an in-feed hopper. Shredders and horizontal-axis crushers, on the other hand, need the metal scrap to be semi-flowable for augers and conveyors to consistently feed the material into the system for modification. The trade-off is that shredders and horizontal-axis crushers can provide continuous volume reduction right at the source (though they can also be utilized as free-standing units).

Bundle breakers can also free solid parts and bar ends that might be trapped in the bundle. Shredders and horizontal-axis crushers alone are not recommended for processing material containing solids such as bar ends and parts pieces.

Shredders, horizontal-axis crushers and bundle breakers typically operate at low speeds with high torque — their drives usually only need to be 2 to 10 horsepower (hp). This can help keep energy costs down.

Now let’s consider a second group of metal scrap modification systems, which includes vertical-axis crushers, rolling-ring crushers and hammer mills. These systems provide more heavy-duty processing compared to the aforementioned devices. Each of these units offers continuous positive-feed operation, enabling them to process high volumes of metal scrap that are too large for conveyors. The end result of these units are flowable, thumbnail-sized metal chips or, in some instances, fine powders. In contrast, shredders, horizontal-axis crushers and bundle breakers produce chips more in the range of 2 to 6 inches in size.

A bundle breaker installs in a conveyor’s in-feed hopper, where dual rotating cylinders agitate the material, shredding stringy wads of chips, turnings and bundles apart to enable processing in downstream equipment. (Photo credit: Prab Inc.)

This group of high-volume systems operate at a lower torque but higher speeds. Vertical-axis crusher motors are usually rated at approximately 20 hp, while motors for rolling-ring crushers need to be upwards of 50 hp. Of these heavy-duty units, vertical-axis crushers are on the lower end of the throughput spectrum — although if floor space allows, multiple units can usually be installed to process higher volumes. Rolling-ring crushers and hammer mills are capable of processing high volumes of material.

Regardless of whether you need a light-duty or heavy-duty metal scrap processing solution, both levels of volume reduction will help decrease storage needs, lower costs for transporting metal scrap and maximize value from a recycler.

But it’s also important to consider updating equipment that isused to recover cutting fluids from metal scrap. There are two advanced options used in the downstream recovery of metalworking fluids: chip centrifuges (also known as chip wringers) and briquetters.

Chip centrifuges dry chips by using centrifugal force to spin cutting fluids off the metal scrap. They can be used as stand-alone units or incorporated into a chip processing system and typically reclaim the highest percentage of fluid.

Briquetters compress the metal scrap into pucks and squeeze the cutting fluid out of it, producing the densest form of metal scrap that recyclers value. However, just because pucks sometimes command higher prices from recyclers doesn’t automatically mean a briquetter is the right option for your operation. Other factors to consider include:

- What is the distance for haul-away transportation?

- What is the volume and type of scrap?

- How much floor space is available?

- Will re-melting be done in-house?

- Is the goal to save coolant costs?

If an operation’s primary goal is to reclaim cutting fluids and lower fluid replacement expenses, a wringer is usually the answer. But if the volume of scrap is high and transportation cost is an issue due to hauling longer distances, then minimizing the size of the material through briquetting would likely maximize value. Aluminum pucks on average weigh about 125 lb./cu. ft. depending on the briquetter manufacturer, unit model, the size of the briquette produced and the density of material before briquetting. Nevertheless, pucks are nearly 10 times denser than loose chips and they enable shops to optimize container fill and save on storage.

A diagonal shaft chip wringer uses more than 600 Gs of centrifugal force to separate oil from crushed chips before pneumatically discharging them into a covered roll-off container. (Photo credit: Prab Inc.)

When it comes to chip centrifuges/wringers, there are three main styles to consider: those that are designed similar to top-loading washing machines, those in which the bowl is oriented more like a front-loading washing machine and those with a diagonal-shaft orientation (think of a top-loading washing machine tilted downward about 45 degrees). In models with a top-loading orientation, it can be difficult to evacuate all the material from the system after operation. This can lead to spent fluid and small metal fines wearing seals out prematurely.

But what’s the trick to getting the most value from chip processing equipment and optimize ROI? Securing the capital for waste stream processing equipment can be a real hurdle, especially for a complete chip processing system. Naturally, stand-alone components (such as a shredder, crusher or centrifuge) are less expensive than systems that integrate those components into an end-to-end chip processing solution. That said, integrated systems offer several benefits.

For example, they maximize efficiency through automated, continuous processing with higher throughput, which usually translates to a faster return on investment. And even though an individual component takes up less space than a complete system, when you add up the combined floor space that individual components require (including space sacrificed to create safe areas/pathways around the equipment), an integrated system will likely take up less space comparatively. Plus, compact turnkey skidded systems that can be moved from one location to another provide flexibility when plant space needs to be reconfigured to meet new production goals.

Finally, knowing exactly what material the equipment will be running is the key to a durable installation. Simulating processing goals by having your material test-run through the equipment being considered is the best way to validate its capabilities. Whether the test is conducted in person or remotely, it will provide valuable insight into the equipment’s effectiveness in your specific application.

About the author: Mike Hook is the director of sales and marketing at Prab Inc.

Read Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)