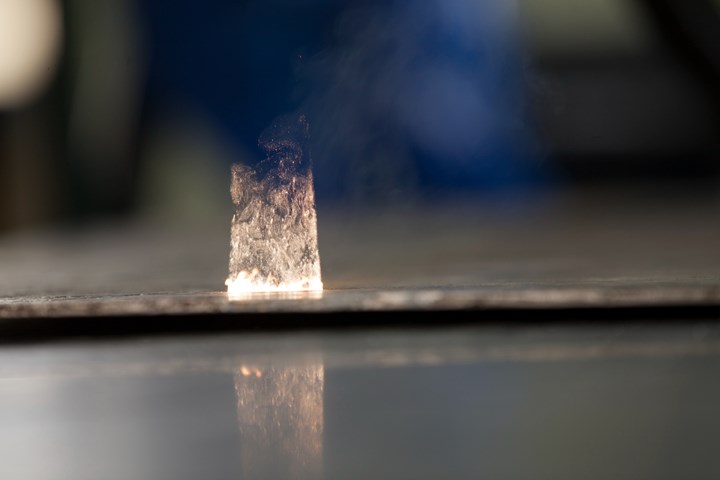

A laser ablation system targets a surface with nanosecond-long pulses of light absorbed by contaminants, which are then transformed into a gas through sublimation. Photo credits: Adapt Laser

Parts cleaning systems traditionally are categorized by either aqueous or solvent systems. But, over the last two decades, progress being made in cleaning technology has offered alternatives to these conventional methods. One of these technologies — laser cleaning — is gaining popularity across many industries in the U.S. because the method is eco-friendly and cost-efficient. Although laser cleaning (more formally called laser ablation) is not the ideal cleaning process for every application, it has advantages for many manufacturers.

The growing use of this technology can be found in industries ranging from automotive, aerospace and defense to power generation and historical preservation applications. Those familiar with laser cleaning may first think of its capability to remove rust and oxidation from workpiece surfaces. However, its applications on new and remanufactured components are beneficial as well. For newly manufactured components, the process is used to prepare surfaces for welding, bonding and coating by removing oils, rust and other surface contaminants without damaging the substrate. In the remanufacturing space, lasers are used for stripping paint, removing coatings and rust/oxidation removal.

Light Duty: The Laser’s Function

Laser ablation can be done manually with a handheld device, in a machine with a dedicated process area, or can be incorporated into a fully flexible robotic cell. Handheld applications are especially useful for low-volume applications that require a large amount of flexibility.

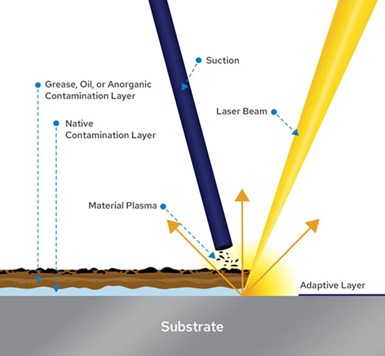

A laser ablation system targets a surface with nanosecond-long pulses of light absorbed by contaminants, which are then transformed into a gas through sublimation. Sublimation is the process of changing directly from a solid to a gas or when contaminants are forced to loosen from the surface due to rapid heating pressure.

The laser itself is shaped using optics that send the beam through a fiber cable that feeds a scanner. The scanner is used to transmit the laser onto the desired surface. After being removed from the surface, contaminants are evacuated through an extraction system where the debris is contained.

The ablation process depends on pulsing, scanning and moving of the beam across the contaminated surface to clean.

The ablation process depends on pulsing, scanning and moving of the beam across the surface to clean. Pulsing, the first step, uses a power source to create a targeted high energy force released in short, controlled pulses to attack the contaminant without damaging the substrate.

Next, the scanning sends pulses through a series of mirrors and optics that guide the pulsing beam across the surface. The scanning process spreads the pulsing laser beam across an area of the part in either a single-dimensional line or a two-dimensional shape. In addition to the shape, the scanning process also controls the speed at which the pulses are transferred onto the surface.

When the area that needs to be processed exceeds that of the pattern produced by scanning, it requires the head to be moved across the part surface using a manual or automated process.

To ensure laser cleaning is successful, the contaminants and the part material that is being cleaned must be considered. The power of the laser, its wavelength, the length of each pulse and the speed at which it moves across the workpiece should also be factors. It is critical to work with the laser system supplier to ensure proper parameters are used to prevent substrate damage during the ablation process.

Seeing the Light or Not? Pros and Cons

Laser ablation is an economical and environmentally friendly alternative to traditional cleaning processes that are often used in similar applications. However, depending on the amount of contamination to be removed and the geometry of the part being cleaned, laser cleaning may not be the ideal cleaning process for an application.

Handheld laser cleaning is often used for low-volume applications that necessitate flexibility.

First, it is critical to understand the benefits of laser ablation prior to making a decision about implementing it. The process’ consumable removal and relatively simple nature make it an attractive option for some manufacturers. Often, traditional cleaning processes are performed with blasting media, dry ice blasting, acid dip tanks, abrasives and other similar processes with high operating costs. These processes generate a large amount of waste that can have adverse environmental effects.

While laser cleaning has many applications where it excels, it is not the proper solution for all applications. For example, if contamination layers are too thick (more than 500 microns) or the goal is to remove solid particles such as metal chips or burrs, it is not an appropriate approach. The parts’ geometry should also be contemplated. Because the ablation process works by targeting a beam of light on the surface, that surface needs to be accessible to the scanner, which is difficult when it is necessary to reach inside small crevices.

More Considerations

When combined with robotics, laser cleaning becomes a highly flexible process that can handle complex parts with repeatable and reliable results. These types of applications may include preparing the surface of gears, doors or other structural components to be welded or removing the excess soot from the surface post-welding process.

Handheld applications are often used for a variety of surfaces and shapes such as the surface of an aircraft. There may also be applications where a traditional aqueous or solvent-based washer may be used to remove chips from a part prior to using laser ablation to prepare the surface for a welding or bonding process.

Ecoclean Inc. | 248-450-2586 | ecoclean-group.us

Content support from Ralf Contzen, CEO, Adapt Laser | adapt-laser.com

About the Author

Tyler Wheeler

Tyler Wheeler is the product line manager at Ecoclean Inc.

Related Content

Kyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreIndustrial Cleaning Shop Zeros In on Precision

This parts cleaning company is elevating its efforts to become a technical cleanliness expert, which presents an exciting, yet sometimes arduous, journey. The ongoing education of the team as well as significant investments in equipment and processes attribute to this shop’s success.

Read MoreOvercoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

Read MoreParts Cleaning Sector Shifts Energy Toward Regulatory Changes

With changes in EPA regulations regarding the use of some popular cleaning fluids, cleaning suppliers and end users are readjusting business strategies and/or cleaning processes to meet new requirements.

Read MoreRead Next

Improve Energy Savings and Efficiency with Vector Kinematics

The rocking, rotational nozzle movement performed by vector kinematics spray cleaning technology combined with temperature and cleaning additives provides an effective, fast and economical parts cleaning process.

Read MoreAutomated Cleaning System Improves Productivity

This rotary basket washer drastically reduced the number of operators tending to the cleaning process as well as removed the bottleneck from that station.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More