Machining In Paradise

One medical parts job shop is taking its business to the next level in Puerto Rico with the right CAM system.

Among the first thoughts that come to mind when hearing Puerto Rico mentioned are cruise ships, baseball, Piña Colada or any other number of other visages of relaxation or vacation. For many of us, high-tech multi-axis lathes and cutting edge CAD/CAM technology fall pretty low on the list of images that come to mind when thinking of this Caribbean paradise. As it turns out, Puerto Rico is a world leader for medical device manufacturing, shipping well over $2 billion worth of medical devices per year, placing the tiny island U.S. commonwealth 8th on the world list of medical device shipments.

Jeff Haley, the Founder and CEO of C-Axis Inc., a Minnesota-based job shop, recognized the unique opportunity for contract manufacturing of medical devices in Puerto Rico and took the plunge by opening a plant there in 2003, just six years after starting his company in Hamel, Minnesota. Since then, C-Axis’s Puerto Rican operation has flourished; growing to upwards of 50 employees to serve a number of the leading medical device companies with major operations there. Many of the world’s largest medical device companies boast extensive operations on this island including such bellwether names as Medtronic, Stryker, Johnson & Johnson, U.S. Surgical among others. Puerto Rico has been an attractive spot for medical manufacturers for a number of reasons including the island’s accommodating tax code and relatively low labor costs.

The key to C-Axis’s growth in Puerto Rico has been its ability to manufacture complex, hi-quality medical parts very efficiently. To do so, it relies on a bank of six multi-axis CNC mills and Swiss type lathes, the most complex of which is a twelve-axis Star ECAS-20T. Of course, when programming such sophisticated parts on such complex machines, being able to quote, program and set jobs up efficiently is paramount. To achieve this efficiency, C-axis relies on PartMaker CAM software to help automate these processes.

“We focus primarily on the medical device industry. We manufacture parts for the orthopedic, neurological, cardiovascular, arthroscopy, endoscopy, oncology and dental,” says Haley. “Some of our biggest challenges include designing the machining process that meets our quality standards, proving out the processes before breaking into the machines productivity and reducing our set-up times. We need a CAM system that allows us to design and troubleshoot our processes off line. This can all be done on an inexpensive computer versus on a very expensive machine tool. Additionally we can examine and optimize the process prior to even starting the set-up. This way, when we load the programs and setup the machine, we are almost done.”

Breaking In to the Business

Haley, a machining and medical manufacturing industry veteran, started C-Axis in 1997 to fill a need in the market he saw for doing short run, prototype medical machining work that larger shops did not seem to be interested in handling. Of course, just seeing a need and having the expertise and equipment to do the work is not enough to succeed in medical machining.

“The medical machining business is a very difficult business to get into. You need to have a proven track record to be accepted by the major medical companies as they rarely take risks with a new or unproven supplier,” explains Haley. “It can take years to get qualified on a project before the real production begins. In the beginning, our prior relationships with some key customers opened the door. These customers took some chance with our company based on their confidence in our people.”

Having been around medical device manufacturing for years, Haley saw the growth in demand from medical manufacturers with plants in Puerto Rico as his opportunity to leap-frog a number of larger, more established competitors. Though already shipping some product to a customer in Puerto Rico but without any commitment to more work, Haley decided he would take the plunge and set-up a Puerto Rican manufacturing operation to serve the island’s exploding medical device manufacturing sector.

Overcoming Challenges

Of course, just setting up shop in Puerto Rico, did not mean overnight success for C-Axis.

“Doing business in Puerto Rico has been a significant challenge,” explains Haley. “We always hear in business that cultural differences are very important and can have a big impact on the success of a business. That is an understatement. We have had a very steep learning curve in all areas of doing business in Puerto Rico. Don’t get me wrong here. The culture and people of Puerto Rico are wonderful. It is just different and you need to work it differently as well.”

One way C-Axis has overcome the challenges of doing business in a very different culture such as Puerto Rico has been to bring experienced staff from the U.S. to play important roles in the company. Dan Heule serves as C-Axis Puerto Rico’s plant manager. Heule got to know C-Axis as a vendor while in management for a major medical device company with operations in Puerto Rico. After spending three weeks in Puerto Rico one December in his previous job, Huele didn’t mind trading winter in St. Paul for 80 degree days all year. Another Minnesotan who works at C-Axis in Puerto Rico is Jeff Geronsin, the plant’s CNC programmer. Geronsin joined C-Axis in Minnesota as a programmer in late 2003, and relocated to Puerto Rico full time by the beginning of 2005. In addition to Haley, both Heule and Geronsin have served to import some of the techniques that have made C-Axis successful in medical manufacturing in the U.S. while incorporating aspects of Latin culture to help the company thrive in Puerto Rico. With a nod to “near-sourcing,” most of the work C-Axis Puerto Rico does serves customers with plants on the island.

“The model in Puerto Rico is that the skill level is very limited because operators only run one machine. We expect more diversity,” says Heule. “There is a four year tool and die school in Puerto Rico. We find that Puerto Rican natives have a good work ethic. I’ve been happy with that aspect. As long as they know the basics, we can teach them the rest.”

“The real difference between the United States and here is relationships. The culture is such here that if you just start talking business with your customers it is a real turnoff. You need to begin discussions by talking about personal things like family and what you did on the weekend. I noticed this when I first began visiting here. The interpersonal relationships are very different in a Latin culture versus a mainstream American culture,” explains Heule.

Automating the Complexity

Highly automated CAM software has been an important factor in C-Axis’s success because it allows the company to program more geometrically complex parts than their previous programming approach allowed, better utilize the advanced, simultaneous machining functionality of their multi-axis Swiss machines and reduce machine set-up time.

The PartMaker software they use is a computer aided manufacturing (CAM) system that allows the user to automatically generate an NC program for a machine tool from an engineering design. The design can be input into the software via a two dimensional drawing or from a three-dimensional solid model.

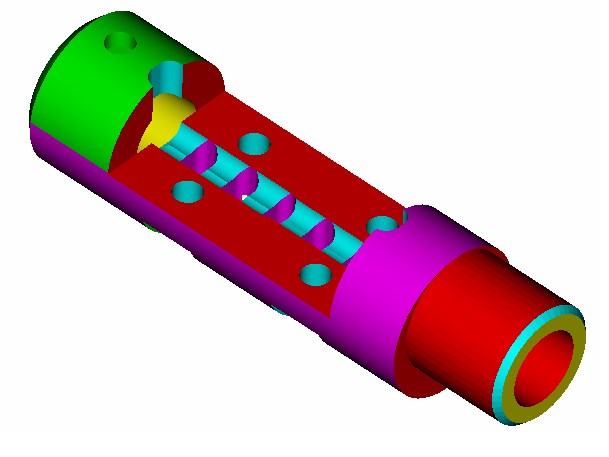

Once geometry has been imported into the software, machining operations are assigned to the geometry in order to calculate tool paths. For programming the multi-axis Swiss-type lathes at C-Axis, their system employs a patented “Divide and Conquer” programming approach which breaks a complex part into individual face windows, where each face window contains the features being machined in a particular plane. For example in one window, all turning operations on the machine’s main spindle are programmed graphically. In another window, milling using the machine’s c-axis capability with a horizontally oriented tool may be programmed, while in another a group of features using the machine’s y-axis with a vertically oriented tool may be programmed.

“CAM is essential to what we do. Without capable software, we just would not be able to do as much complex milling as we do. Even basic programming can be done in half the time that it used to take writing it manually versus doing it with PartMaker,” says Geronsin. “For example, if we are milling out pockets and decide to change an endmill size, this software can do the math in seconds which could take hours when programming manually.”

The ability to program more complex parts efficiently has been critical to C-Axis for meeting the demands of the medical device industry. “Medical parts require a level of perfection generally not seen on other types of devices. They are like little pieces of jewelry, because doctors want to see them looking beautiful. The medical field is unique because the cosmetic look of the part is very important to customers. As a result, we’ve had to get into doing surface machining our Swiss machines. Without this sophisticated software package, we’d have had to ‘no quote’ those components,” says Geronsin.

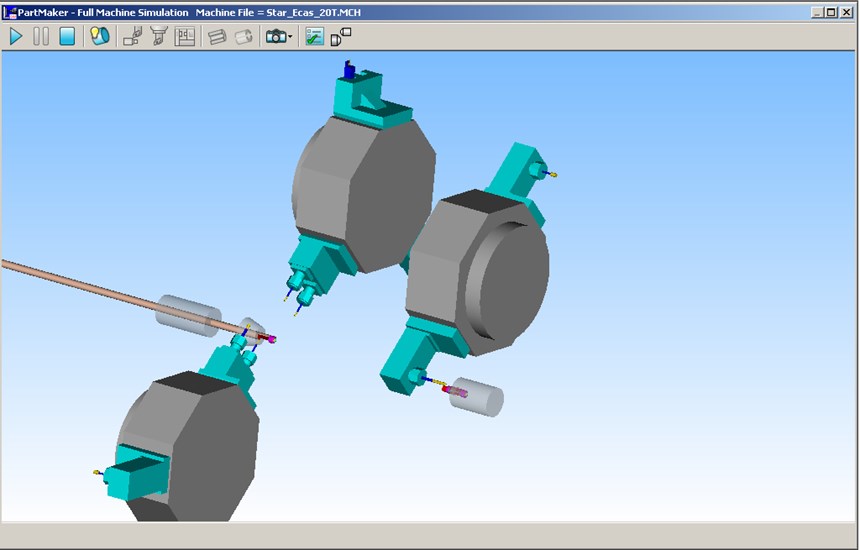

The geometric complexity of the medical parts C-Axis is making is compounded by the complexity of their multi-axis Swiss type lathes. Two of their Swiss machines, a Star ECAS 20 and ECAS-20T require three simultaneous CNC programs to be written to support the machines’ numerous axes. A CAM system for these machines must allow the user to quickly synchronize the machine’s numerous programmable axes to achieve the most optimal cycle time. The software does so by deploying a unique, Visual Synchronization technology that allows the programmer to choose a diagram of the synchronous strategy he wants to use, such as cutting with one tool on the main spindle while another tool is cutting on the sub-spindle, or cutting on the main spindle while the part is being supported on one end by the sub-spindle.

Once the synchronization strategy has been set, the software displays a visual time study, showing the amount of time being spent on the main spindle, the amount cycle time on the sub spindle, and the overall cycle time incorporating overlapping machining time. The results are shown in the form of histogram that clearly indicates where additional opportunities for time savings exist. If the programmer has tried to synchronize operations in a manner his machine cannot handle, the software will point out the error before allowing him to proceed. The software then automatically inserts wait codes in an NC program saving a measurable amount of programming time.

“One of the most beneficial aspects for C-axis is the software's ability to do complex tasks like place all the wait codes on a three channel system without the machine alarming out,” states Geronsin.

Once the process of developing tool paths and performing process synchronization is complete, the part can be simulated on screen in a vivid 3D simulation. This allows the programmer to see what the part will look like before committing machine resources. It will also detect any tool collisions or machine crashes. With parts getting smaller and more complex, this visualization capability is critical. “Through simulation, you have the ability to visualize your part and make adjustments without shutting down a machine,” explains Geronsin.

More Accurate Quoting

“In our business it is very easy to underestimate a project. Unfortunately, when you do that you usually get the job. Every machine shop will tell you that they have a few losing jobs. How much does that cost? Or how comfortable are we to approach a customer to advise them that we underestimated the job and will have to increase prices?” asks Haley.

PartMaker employs a knowledge based machining approach which stores a shop’s specific knowledge of tooling, materials and feeds and speeds allowing it to automatically apply the machining expertise of its people from one job to the next. This technology lets the software learn from the user and as a result generate more accurate time studies for a part as a byproduct of the programming process.

“After we have optimized the software settings to match our machine tools, materials and tooling we are able to get accurate cycle times for use in quotations. This has been a huge advantage for our company. If you have not or are not making a similar part and use conventional methods for developing cycle times you are only guessing,” explains Haley.

Related Content

PMTS 2023 Product Preview: Swiss-Types

Learn about some of the latest Swiss-type solutions that will be on display at PMTS 2023.

Read MoreShop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

Read MoreStories of Swiss First Additions

A handful of shops share their stories about the how’s and why’s of adding their first Swiss-type CNC turning centers.

Read MoreMoldmaker Finds Value in Swiss-Type Machining

This multifaceted manufacturer has added CNC sliding-headstock turning technology to complement its established mold tooling production and new injection molding capabilities as it continues to pursue complex medical work along a vertically integrated path.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More