During its search for a Swiss-type lathe with a Y2 axis, Paramount Machine realized the potential advantages of a machine with both a Y2 axis as well as a programmable B axis that could create contours and features at various angles.

Salt Lake City’s Paramount Machine serves a diverse customer base, producing parts and assemblies for aerospace, defense, medical, mining and many other industries. Led by owner, Steve Van Orden, the 65-person manufacturing company similarly has a range of machining equipment in its climate-controlled facility, including VMCs, HMCs, CNC lathes, turn-mills, wire electrical discharge machines (EDMs) and, prior to 2017 anyway, one Swiss-type lathe.

Today, though, the shop has six Swiss-types.

Steve’s son Eric, the company’s screw machine lead and turning technical advisor, says that while Paramount Machine’s first six-axis Swiss-type offered live tooling to potentially machine parts complete, it lacked a Y2 axis, limiting the types of operations that could be performed on its subspindle.

This spurred the shop to seek another Swiss-type that offered a Y2 axis. But, during this search, it realized the potential advantages of a machine with both a Y2 axis as well as a programmable B axis which could create contours and features at various angles, in addition to offering more tooling capacity. In fact, such features seemed particularly enabling for more efficient machining of a family of X-ray components which the shop had traditionally run across multiple machines.

The shop produces a variety of parts on its six Swiss-types. It now aims to run any part 1.5 inches in diameter or smaller across those multifunction machines.

“Our original process for one part in that family featured two operations on a chucking lathe, a milling operation, a wire EDM operation and another milling operation,” Eric Van Orden says. “We felt a Swiss-type with a B axis would be capable of manufacturing this part whereby it’d simply go from the Swiss-type to the wire EDM before shipping it to the customer.”

In addition, there were other jobs Paramount Machine ran that required angled milling, drilling and tapping which the company felt would benefit by having a Swiss-type with a B axis.

After considering multiple solutions, the shop purchased a 32-mm Tsugami SS327-5AX from REM Sales. This was five years ago. Van Orden says besides the Y2 and B axes, this machine was chosen for a few other reasons. One, he admits, is perhaps old school. He says this machine is heavier than other Swiss-types, which contributes to its rigidity, and has high-power motors for both the main and subspindles. The shop also appreciated the advice and timely assistance REM Sales associates such as John Traver and Steve Tragarz provided, as well as prompt maintenance support.

Per the latter, Van Orden cites one instance in which the shop had damaged the way cover on the machine’s subspindle side while in the middle of a hot job. “We called Tsugami/Rem Sales right at closing to see how quickly it could have a replacement delivered so we could safely continue running the machine. Not only did it have a replacement in stock but a member of the team drove the part to UPS on his way home so it would arrive to us the next day. We received the part first thing the following morning and the machine was back up and running pretty quickly.”

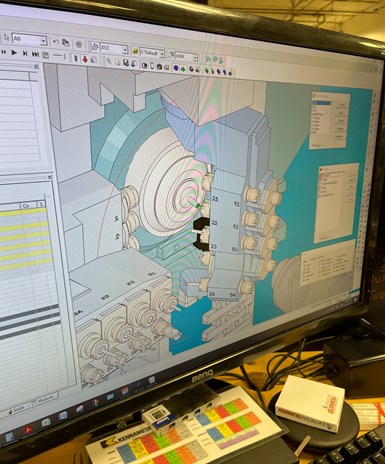

Van Orden also feels Paramount Machine has benefited by programming this B-axis machine using the Esprit CAM software it had used for other machines in the shop and using the software provider’s postprocessor developed specifically for the Tsugami SS327-5AX.

Eric Van Orden points to the value of simulation within Esprit CAM software as well as its ability to easily create multiple work planes to eliminate the need to set up tools with different angle offsets.

“Our goal is to create a full solution that doesn’t end at making tool path in the CAM system, but rather ends with machine-optimized G-code that will run error-free on your machine,” says Nick Zentil, director of North American sales for Esprit Cam. “When you get into a complex machine tool such as an SS327-5AX, you need a postprocessor that enables you to access the machine’s full capabilities. We work very closely with the Tsugami/Rem Sales applications team to develop posts for Tsugami machines that do exactly what they are supposed to do. That is, create edit-free code.”

“I have complete confidence that as long as I set the tools correctly in Esprit CAM, I can take that code, post it, put it in the machine and run it without any issues,” Van Orden says.

He also points to the ability to easily create multiple work planes within Esprit CAM. This enables programmers to select features off of a solid model and create work planes from that model. The software automatically determines the proper workplace direction based on the tool to machine the feature. This eliminates the need to set up tools with different angle offsets.

But, how much production time was reduced by consolidating operations for the X-ray component on the Swiss-type? “We were able to replace three separate machine cycles with one Swiss process, and the overall part cycle time was reduced by 92%,” Van Orden says. “Not only was this a dramatic time savings for us but it also eliminated work-in-process parts that were previously staged throughout the shop.”

Of course, this was a big win for this particular family of parts. But, ultimately, the benefits of this second Swiss-type led to a more wholesale change in terms of what work it would run across its now multiple Swiss-types as well as a deeper dive in terms of how to maximize the potential of this type of multifunction machining platform.

Boosting Swiss-type Flexibility

Recently, Paramount Machine has seen increased demand for small parts largely for aerospace applications. While it was possible to run such parts on larger chucker lathes, the shop felt it made more sense to keep feeding bigger jobs to those machines. That’s one reason for purchasing a Tsugami SS207-5AX 20-mm Swiss-type with B axis soon after the first B-axis Tsugami. In addition, Paramount Machine has added another SS327-5AX as well as two Tsugami B0386-III 38-mm machines over the last couple of years.

These additions have led to a change in strategy for the shop. “Over the years, we’ve become so effective with the Swiss-type platform that now, virtually every job less than 1.5 inches in diameter runs on those machines instead of conventional chuckers,” Van Orden explains. “And, while typical production runs range from 500 to 1,000 pieces, we’re not afraid to set up those machines to run only five parts.” In addition, live-tool capability on the Swiss-types often eliminates any second-op work on a mill that might otherwise be needed for parts that initiated on the chuckers.

“We're not afraid to run five pieces on a Swiss-type.”

All of the Tsugamis are “convertible” models, and one part of the shop’s strategy with its Swiss-types is keeping them in chucker mode most of the time and scheduling accordingly, unless a job requires a guide bushing. Van Orden says these machines run in chucker mode 80% of the time. This helps by reducing changeover time to new jobs. That said, he notes that the time to change from chucker and guide bushing modes is only 30 to 45 minutes.

Paramount Machine has found that a step-magazine-style barfeeder is particularly helpful with small-diameter bars to prevent double-loading.

Other efforts Paramount Machine applies to maximize the benefits of the Swiss-types include:

Deburring parts on the machine. The value of multitasking machines such as Swiss-types is the potential to machine parts complete. However, if a part still requires deburring, it’s not complete. Therefore, Paramount Machine uses deburring cycles on its Swiss-types that Van Orden says has eliminated approximately 60% of manual deburring that would otherwise be required. For machines with a B axis, it can use a chamfer mill and contouring tool path to reach the entirety of the part to deburr it using only that tool. This often wouldn’t be possible on machines without a B axis that have perpendicular and parallel constraints.

Performing oscillation cutting. Tsugami’s oscillation cutting technology oscillates a servo axis (either X or Z) to help break chips in tough-to-cut materials and reduce heat in the cut because the tool goes in and out of the cut. Van Orden says the shop has used this function for aluminum parts that have had notorious chip issues, as well as for roughing 17-4 stainless parts. In addition, it is commonly used during parting-off operations to help break chips and eliminate long “stringers” that tend to wrap around a part.

With this technique, cutting is performed by synchronizing the oscillation of the specified axis with the rotation of the main spindle. Interruption in the cut breaks material into small chips. This function is software driven, so no extra equipment is needed as the machines are designed to support oscillation cutting. Oscillation cutting is performed by specifying the initiating G code (G8.5P2), and the function remains valid until cancelled by a subsequent G code (G8.5P0). Oscillation data is automatically calculated based on the main spindle speed and the feed rate of the specified axis.

For outer diameter turning, tool shanks/clamping units remain installed in the gang plate and individual heads with quick-change inserts such as those shown here can be easily swapped.

Using quick-change tooling. Paramount Machine uses quick-change tooling to speed and simplify setups on its Swiss-types. One example is the KM micro system from Kennametal for outer diameter turning. For this, tool shanks/clamping units remain installed in the gang plate, and individual heads with inserts can be easily swapped. Similarly, the shop uses modular drilling units from Iscar for larger applications in which the drill body remains installed in the machine and drill heads screw in and out of.

Eric Van Orden demonstrates the software Paramount Machine developed in house to track tooling availability and consumption from the three different vending systems the shop uses.

Being open to new cutters. Van Orden says the shop remains open to testing new tooling that it feels might be beneficial. He notes that tooling representatives visit the shop every other week, if not every week. It also is not locked in to one particular tooling vendor. While there might be pricing advantages in doing that, there might not be performance advantages taking this approach, he notes. In fact, Paramount machine uses vending systems from three different companies that are connected via software it created in house which tracks tooling availability and consumption.

Lights-out Considerations

Paramount Machine strives for lights-out production and there are various process elements it has considered which give it the confidence to enable machines to safely run unattended for long stretches of time on its Swiss-types.

Automated carousels collect parts in bins on a rotary table that indexes at specific time intervals. If parts measured in the first and last bins are within specification, it can be assumed that those in the bins in between are, too.

For example, the shop has a few different brands of bar feeders. The 20-mm Swiss-type uses an Iemca Elite 220 step-magazine style in which stepped guides rise and lift bars which will then fall into the guide channel. Van Orden explains that the step-magazine style is particularly helpful with small bars such as the 1/8-inch-diameter material it commonly runs on that machine. He says the shop has experienced bar feeders that feed bars into the guide channel via gravity sometimes double-fed bars of this size, if adjustments were not set perfectly. In some cases, this led the shop to manually load new bars one at a time. That’s no longer an issue with the Elite 220.

On the other side of the Swiss-types, Paramount Machine uses iSwiss Smart Tables to not only catch and collect parts but also sorts them into pie-shaped bins attached to a rotating table. (The Smart Table automated parts carousel is manufactured by Pressure Tech, a New England Tool Corp. company, and distributed by iSwiss.) These units can be programmed with an M code to index to a new, empty bin after a certain part count or specified amount of time. Paramount Machine takes the latter approach. By batching parts in this way in multiple bins, the shop can measure parts in the first and final bins, and if they are within specification, it can be assumed that those in the middle bins are as well.

The shop is applying lessons it has learned from using its B-axis Swiss-types to its new DMG MORI NTX 1000 machine, such as using that machine’s B axis to perform operations such as continuous contour turning.

Monitoring tool life during lights-out machining is important, too. Van Orden points to a high-volume job that it ran 700 pieces overnight. Originally, it used macros to change a tool when it was approaching end of life during that run. But, that meant for one of the part’s critical features, the process had to be set at the top of the feature’s tolerance and would then degrade to the bottom of the tolerance by the end of the run. So, the shop ran 100 pieces and measured to see where that tolerance ended up due to tool wear. After determining that, it added macros to adjust the tool offset when necessary during the run (after X number of parts) so that feature always remained close to its nominal value. The shop has also found that purchasing higher quality tooling that lasts longer is helpful in minimizing the number of tool changes or offset adjustments in a lights-out environment.

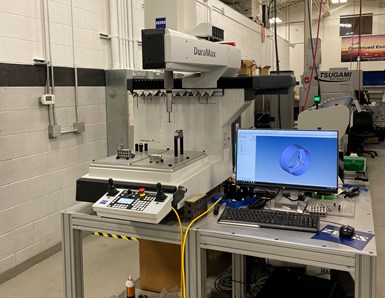

Deploying shopfloor CMMs in different areas of the facility has increased in-process inspection capabilities.

Moving Forward

Paramount Machine has recently added a few Zeiss DuraMax shopfloor coordinate measuring machines (CMMs) in different areas of the shop, which has increased its in-process inspection capabilities as well as improved overall quality as it continuously strives for. The shop is also considering software to track machine utilization. It has done a bit of that using the Messenger monitoring and history analysis platform available on its DMG MORI machines. This, Van Orden feels, will help the shop refine its lights-out machining efforts. But, while it’s really easy to collect data, he notes it sometimes isn’t as easy to interpret and analyze information in an effort to help make more informed decisions on the shop floor.

Related Content

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreRead Next

Video Tech Brief: Dual Thread Whirling on a Swiss-Type CNC Lathe

The dual thread whirling units on Tsugami Swiss-type lathes can produce medical bone screws with two different thread leads in one setup, eliminating the need for single-point threading.

Read MoreDigital Twin Makes CNC Programming Easier

A digital twin helps to reduce or eliminate any surprises that may occur during the machining process.

Read MoreVertical Integration Enables Rapid Manufacturing Response

For this contract manufacturer, having myriad machining and manufacturing capabilities in-house enables it to deliver assemblies to customers faster and with higher quality.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)