Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Making screw threads on parts that are only 0.012 inch in diameter requires unique skills, but such micro threads are required for a large variety of products, such as watches, eyeglasses, cell phones, cameras, circuit boards, medical devices and miniature aerospace safety and control devices.

The three basic micro thread systems are the unified miniature screw threads (indentified as UNM), small ANSI B18.6.3 inch-based threads and the standard ISO metric threads that include a few micro sizes. As an indication of the size of these micro threads, the height of a 0.5 UNM thread is only 83.8 microns (0.0033 inch). For this article we define micro threads as having a pitch of 80 threads per inch (TPI) or more.

Six different processes can be used to produce micro threads: tapping, conventional turning, thread chasing, thread rolling, grinding and electrochemical grinding (ECG). Thread chasing and thread rolling are performed on lathes, with tools other than a conventional v-groove tool.

Tapping

Micro taps are available in special alloy high carbon tool steel, hardened high speed steel, TiN-coated HSS, and in TiCN-coated HSS. As many as eight different tap geometries are available in some sizes.

Hard to machine materials often require the use of the upper end of the allowable drilled hole tolerance to prevent tap breakage. To be successful, a shop should establish its own minor and major diameter limits, but it could be restricted to working with only about half of the allowable tolerance to prevent breakage, yet still produce an acceptable “complete” thread form.

Cutting taps with ground flutes, but unground threads, though less expensive, break more often than those with ground threads. But these taps can be successful on aluminum parts. Micro-size fluteless cold forming taps, effective in soft materials, typically break in harder materials.

Tabco Optical Inc. (Fallbrook. Calif.) is one of the few companies that supply micro taps as well as finished screws. Company President Steve Boudreau operates a precision micro manufacturing facility that produces special design parts for the medical and commercial industry.

Mr. Boudreau sells several sizes of microtaps, including 0000-160 to 0-80, and 0.5 mm to 1.4 mm. He even has a few left-hand taps in these sizes. The taps are available in hardened high speed steel, and many can be purchased with TiN coating. He is also beginning to offer TiCN. The coated taps get three times the life of uncoated tools. In the 300 series stainless steels, taps can have lives of 500 to 1,000 or more holes, although not in harder materials. The selection of tap styles depends upon size, but in some sizes, he sells a plug tap, a bottoming plug tap, a roll form tap, and a roll form bottoming tap. Cutting taps are provided with three flutes.

Mr. Boudreau explains that fixturing is critical for the micro taps because they break easily if not started straight. Precision locating below the spindle is essential. On screw machines, he uses Rego-Fix axial compensation collets for micro tapping.

J.I. Morris Company (Southbridge, Mass.) is a large manufacturer of miniature screws and a supplier of taps and gages. The company’s gages range from 000-160 to the larger sizes, and its taps include plug, bottoming, taper and gun taps. Some are three-flute tools, while others are two-flute. Taps begin at 0.3 mm and consist of the entire UNM series. Sizes below 1 mm are two-flute. Morris is one of the few suppliers that have gages for these threads. Alouette Tool Co. (Fairport, N.Y.) also provides taps, button dies, threading tools and gages.

Miniature Lead Screw Tappers

Lead screw tappers can easily produce some of the larger micro sizes, but few, if any provide that capability for the small sizes. The most sensitive tappers have adjustable torque limiting controls that automatically reverse the spindle, clear chips and then resume tapping to preset depths.

The smallest lead screw tapper from many suppliers is for the 0-80 TPI range, but the Milman T-700-3 was designed to tap all of the UNM sizes. The T-700-1 was designed for the 80-200 TPI threads. Milman Engineering (Rochester, Wash.) no longer makes these machines because of the lack of demand, but the company supplies repair parts for the 500 machines in use. Today’s Milman LT-250 can produce 0-90 threads.

Turning

Micro screws are commonly produced on automatic screw machines. The threads can be cut with v-groove tools such as with conventional threads, with thread chasers (disc-like holders with three or more mini cutting points), with button thread dies, or with thread rolling tools.

Customers can make their own Swiss automatic cutters for threading or buy from tool makers. Sandvik’s Kevin Wilson (Kansas City, Mo.) notes that the CoroCutXS provides a 0.2-mm pitch (127 threads/inch) threading tool for Swiss machines. These are used daily in steel by some automotive suppliers. WhizCut (Little Rock, Ark.) also produces carbide inserts for 1.0-mm threads (0.25-mm pitches).

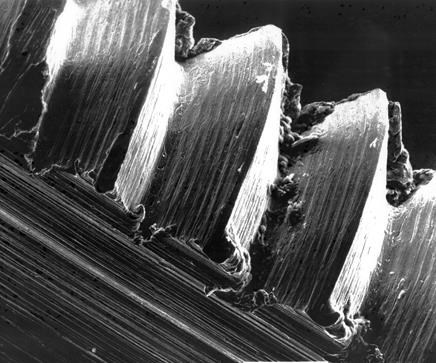

Thread chasers are available for these machines in both full thread and staggered tooth (half thread) configurations. Finding thread chasers in the UNM sizes is a challenge, but J.I. Morris offers 0.8-UNM and larger HSS ground thread tools. In hard materials, chasers may produce only 150 to 200 parts before wearing out.

Button dies could be a better solution than chasers. In hard materials, they can produce 300 parts for each die and are less expensive than chasers. These simple tools, though, produce obvious burrs and leave sharp thread crests. Button dies are available in 1 mm and larger.

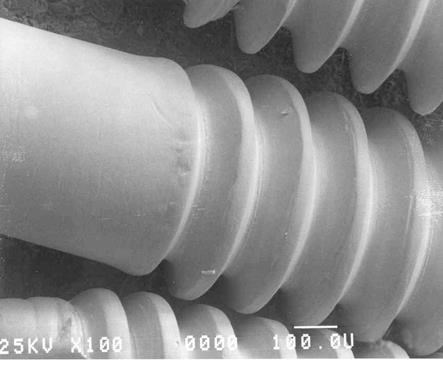

Thread Rolling

Thread rolling, which cold forms the thread, offers better thread surface appearance, tolerance and much longer tool life than cutters. It has a number of advantages over thread cutting:

- Thread crests are round rather than sharp.

- No loose burrs are produced on the threads.

- The surface finish on the threads is very good.

- The resulting thread form is excellent.

- The feed rate can be double that of cutting processes.

- For many applications, tool life will be at least 1,000 parts per tool, and the cost per tool will be less than that of button dies.

- Cold formed threads are stronger than cut threads.

- Forming forces can be significantly lower than in cutting.

Thread blank diameter is very important for correct rolled threads. A 2.4-micron (0.0001 inch) increase in blank diameter increases thread form by 10.1 microns (0.0004 inch). Both thread form and size can be varied by varying part blank size and spindle speed and by adjusting thread rolls. It is important to start with a slightly undersize blank, and then adjust it outward until a full thread form is reached. Slightly oversize thread blanks will crack or chip thread rolls.

Thread rolling will push material out, extending the end of the part, which may require modification to thread specifications or a subsequent end finishing operation. Because rolling stretches material, the end thread on long threads may not meet the required pitch spacing.

Tabco’s Mr. Boudreau uses Habegger thread roll dies from Switzerland in his screw machines for rolling threads. They are available from Alouette Tool Co. in adjustable sizes from 0.6 mm and larger. Nonadjustable thread roll dies are available from 0.35 mm and larger.

Antrin Miniature Specialties (Fallbrook, Calif.) is a screw machine shop specializing in miniature parts. Anne Odermatt, V.P., and Oscar Lomeli, president, use thread rolling to produce threads as small as 0.4 UNM in both 303 stainless and A286. While screws are common aerospace and electronics products for the company, they have also threaded the ends of wires that were 6 inches to 6 feet long for use in medical applications.

Thread Grinding

James Vosmik, president at Drake Manufacturing Services Co. (Warren, Ohio) says his company’s GS TEM-Mini grinder is able to produce M0.5 × 0.125 pitch threads (203 tpi) on hardened high speed steel to make forming taps. These and other taps M3 and smaller are used for consumer electronics, such as the backplate of Apple’s iPad, in multiple materials including stainless steel. He notes that users are requiring him to develop software that accommodates nonstandard relief on the forming taps. So Drake has developed a CNC software program that allows users to draw any thread relief configuration they need and then translates that dxf file into machine controls for producing that shape on the tap. Several of these users have proprietary forms, and each wants a different form that they believe gives the forming tap long life in a certain application.

Electrochemical Thread Grinding

Neil Ashbaugh, senior marketing support specialist for Oberg Industries (Freeport, Pa.), notes that his company electrochemically grinds to get smooth, totally burr-free threads on such products as 1-mm nitinol screws with 101 threads per inch. The company purchased and enhanced an ECG process that it calls MDP (molecular decomposition process). According to Mr. Ashbaugh, commercial machines do not offer the fine detail Oberg needs, so they design and build their own machines, develop their own algorithms for the power supplies, develop and produce their own wheels, and tailor their own biodegradable electrolytes. This customization gives the company the flexibility to tailor solutions and wheels to be as aggressive or mild as necessary for each specific application.

ANCA Inc. (Wixom, Mich.) is a commercial supplier of ECG machines that can produce micro threads. The Anca TapX grinder is used to make industrial taps and special medical taps.

Inspecting Micro Threads

Measuring micro threads has a host of potential issues, and users probably will need to write their own acceptance standards for these micro threads. There are also many reasons users should inspect gages, taps and purchased screws to assure they meet their defined standards:

- Acceptance gage standards do not exist for some sizes.

- Hard (physical contact) gages wear part threads beyond limits.

- Many suppliers do not list the acceptance class of their gages.

- Purchased UNM thread ring masters may be incorrect.

- Purchased thread form comparator charts may have root errors and may have more tolerance than allowed by federal standards.

- Thread wire inspection may not agree with 160× visual inspection.

- Purchased thread gages may arrive with burrs on them.

- Micro thread gages break easily. Having an adequate supply of gages may be an issue.

- Male centers on gages may make them unacceptable for use in blind holes.

- Users need to determine their measurement uncertainties and incorporate them into their acceptance standards.

- Surface texture or finish on micro threads may not be acceptable.

According to the UNM thread standard, “Contact gaging, such as the use of go and no-go ring gages, measuring wires and set plug gages, may be used for sizes 0.70 UNM and above.” No-go cylindrical gages should be used first, and inserted into the hole only once because repeated insertions can wear the minute threads beyond tolerance limits. Then a go cylindrical gage should be used, also inserted only once.

Thread Check Inc. (Ronkonkoma, N.Y.) offers a full range of 0.3- to 1.4-mm unified miniature screw rings and plug gages to measure external threads and internal threads. The line includes go, no-go and set ring gage sets.

Related Content

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreData Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreNew Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

Read MoreRead Next

Tooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)