Manufacturing in the US Economy — and Our Place in It

Manufacturing is essential to our economy and Precision Machining is just as essential to manufacturing.

Manufacturing is the fourth largest segment of the U.S. economy. Counted by itself, manufacturing in the U.S. would be the eighth largest economy in the world. Manufacturing created 11% of value added to the U.S. GDP in 2021. In 2020, U.S. manufacturing output was $2,345 billion. Manufacturing directly accounts for 8.6% of the U.S. workforce (about 12.2 million people), 60% of U.S. exports, 55% of patents and 70% of research and development (R&D) spending, according to the National Association of Manufacturers (NAM) and a McKinsey & Company analysis of U.S. Bureau of Economic Analysis (BEA) and U.S. Bureau of Labor Statistics.

However, manufacturing relies on inputs from other sectors in the U.S. and global economies — energy from fuels and utilities; materials from mines and mills; machines, tools and equipment for production; packaging and freight services for our raw materials and final products; accounting; and other services. All of these are important inputs to manufacturing success. Purchases of these inputs by manufacturers lead to an enhanced final demand in the broad economy. This is called the economic multiplier and the U.S. B.E.A. calculates that one dollar’s worth of final demand in manufacturing results in an additional $2.68 of total impact to the overall economy. Manufacturing investment leads growth.

In the U.S. Midwest, we tend to think that manufacturing is just another word for metalworking. In fact, chemicals, computer and electronic products, and food, beverage and tobacco products are the top three manufacturing sectors by dollar output. Aerospace and other transportation equipment, motor vehicles and parts, and machinery are segments that we serve — and these all have greater sales than our sector.

Fabricated metals, classified as NAICS 332000, is the name of the industry in which our precision machining/contract manufacturing shops are classified. It is the seventh largest sector in manufacturing — in 2019, fabricated metals products output was $161.2 billion.

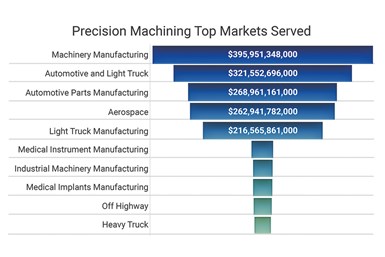

Precision machined products (our industry segment) is classified as NAICS 332721. In 2018, which is the latest data available from the U.S. Census, our industry sales were $20.8 billion, or almost one-eighth of the output

of the fabricated metals industry. Our top 10 largest markets served, according to 2018 U.S. Census data, are shown above.

Manufacturing is important. It is the fourth largest segment of the U.S. economy. Arguably, nothing in our economy would function without the critical technologies that our precision machined components enable — machinery, mobility, aerospace and medical. I am fond of quoting Lothar Horn, CEO at PMPA technical member company Horn USA, who stated, “No car runs, no aircraft flies and no hip replacement is fitted by a doctor without precision tools having previously been in use.”

Precision tools are skillfully employed by precision machinists at precision machining contract manufacturing shops like yours. What you make matters. Your decisions on part quality and acceptance make a difference. A difference that matters. We make parts for “can’t fail” applications. Applications where critical human safety is the expected outcome — and one that we take for granted every day.

Our production may be just one-eighth of the seventh largest manufacturing industry, which is itself the fourth largest sector of the U.S. economy. But, every day, people live well because we are the hands of the physician, the enablers of mobility and transportation, and the suppliers of essential and critical infrastructure to keep our economy thriving. Economics may be a dismal science, but this peek into the economy of manufacturing makes me proud of our performers, their talent and their accomplishments. Precision machinists — we make the things that make a difference. About $20 billion worth each year!

Links

- NAM

bit.ly/PMPA-PM1222a

bit.ly/PMPA-PM1222b - McKinsey & Company

mck.co/3DeVk1X - Statista

bit.ly/PMPA-PM1222c - U.S. Census

bit.ly/PMPA-PM1222d

Read More Articles from PMPA:

About the Author

Miles Free III

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email – mfree@pmpa.org; website – pmpa.org

Related Content

Craftsman Cribsheet No. 128: Why Do Machinists Say Tenths Instead of Ten Thousandths?

In machinist parlance, a tenth is a tenth of a thousandth, not a tenth of an inch.

Read MorePrecision Ground Barstock: How It Is Manufactured, Benefits to Your Shop

Understanding the benefits provided by precision centerless ground barstock can help you avoid false economy and optimize the work you quote by maximizing benefits to your manufacturing process and customer.

Read MoreKeeping It In The Family — Succession Tips From Those Who Lived It | Part 1

PMPA members share some tips to avoid getting burned when passing the business torch from one family member to another.

Read MoreTurned and Polished Steel Barstock: How It Is Manufactured, How It Impacts Your Shop

Understanding the benefits provided by turned and polished steel barstock and its differences from cold-drawn steel barstock can help you and your team avoid unexpected performance issues.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)