Meet Production Machining’s 2020 Emerging Leaders

This year’s 10 Emerging Leaders have many character traits in common that shine well beyond the buildings in which they are employed. Their leadership skills and willingness to help others grow within their skill sets has proven that the precision machining industry’s future is bright in the hands of these talented individuals.

In the uncertain times we are living in, it is refreshing to hear uplifting stories about young talent in the precision machined parts industry who are striving to make a difference within their organizations. We call them our Emerging Leaders. Their eagerness and fast-learning, think-outside-the-box mentalities have shined through to their managers, co-workers and industry partners. They are selfless individuals, under the age of 40, who face — and even welcome — challenges head-on. Many have transformed the companies at which they are employed, making these businesses more competitive, efficient, organized and overall better places to work.

After learning about each of these Production Machining 2020 Emerging Leaders, it’s easy to see why their nominators (their peers) chose them for this award. Our hope is that these stories inspire other individuals within the industry to do more than what is asked of them, and to be innovative, creative and enthusiastic team members who organizations do not want to function without, just as these Emerging Leaders have become.

Clay Adcock, Manufacturing Manager, Custom Tool

In August 2011, Clay Adcock walked into an interview at Custom Tool (Cookeville, Tennessee) with no experience in manufacturing, much less the machining trade, as his background was in auto mechanics. He made a promise to be the best worker the company would ever hire, if given a chance.

Clay Adcock knew he made the right choice working in manufacturing early on in his career at Custom Tool.

Within two years, he had excelled at learning the company’s two-axis turning centers and began learning its turn-mill machines, which he excelled at a year later. He began leading the company's goal of achieving lights-out production as part of the standard operating procedures. Adcock’s transition into management-related tasks began in 2015 and led to his current manufacturing manager position, which includes production floor management along with new technology implementation.

“While completing my assigned tasks, I gained thorough knowledge of machining and CNC controls through self-directed study and conversations with journeyman machinists,” Adcock says.

He knew he made the right choice working in manufacturing early on in his career at Custom Tool. “I realized that in manufacturing, especially a machine shop, you can never stop learning no matter how long you’ve been in the industry,” he says. “I enjoy being knowledgeable and being able to answer questions or have solutions when needed.”

Although Adcock says his advancement within the company has come from leading efforts in lights-out production, robotic machine tending, robotic welding and many continuous improvement efforts within the company, his nominator believes his success stems from other sources.

“Clay's rapid progression to this point is due to his lead-by-example attitude, his commitment to achieving company goals and objectives, a tremendous work ethic, genuine respect for his co-workers and a tremendous attitude of humility,” says his nominator, Bob Young, company vice president.

When asked about a time when he thought outside the box to complete a task, Adcock says his idea was successful. “One time, we had a job for a part that was rectangular and I thought it would be best to run on a CNC mill,” he

“Clay's rapid progression to this point is due to his lead-by-example attitude, his commitment to achieving company goals and objectives, a tremendous work ethic, genuine respect for his co-workers and a tremendous attitude of humility,” says his nominator, Bob Young, company vice president (left).

explains. “But after thinking about a better way to machine the part, I realized that we could turn certain features faster than we could mill them. So, I presented the idea, we made a special fixture and finished running the job using that approach.”

In 10 years, Adcock would like to advance to a position of overseeing the company operations. However, leading up to that goal, he would teach the next generation of Custom Tool employees to do his current job. He enjoys helping others advance in their skill sets.

“He is respected by his co-workers because he desires success and growth for them as well as himself,” Young says.

As an Emerging Leader, Adcock hopes to have a greater impact on the manufacturing industry by being an ambassador for the trade. “When we have shop tours for students and instructors, sharing the company’s journey and sharing my experiences over time is important,” he says. “Most everything in our lives is touched by manufacturing, so manufacturing is going to continue. Manufacturing is diverse. It offers a range of career paths where you have the opportunity to find a niche doing something you enjoy.”

Jerry Eighmy, Business Team Leader, American Turned Products

For the past five years, Jerry Eighmy has been an integral leader in developing people, processes and plant-level lean initiatives at American Turned Products (ATP). As business team leader, Eighmy holds a supervisory

Jerry Eighmy holds a supervisory role where he oversees all shifts for manufacturing operations, managing about 40 employees at the company’s Erie, Pennsylvania, facility.

role where he oversees all shifts for manufacturing operations, managing about 40 employees at the company’s Erie, Pennsylvania, facility. Eighmy began his career at ATP as its buyer, which gave him ground-level experience to help him understand the business and how to positively impact the organization.

Eighmy is the son of co-owner Scott Eighmy, making him a third-generation family member working at ATP. “Being the son of an owner can be a struggle on many levels, but Jerry has been able to really shake the stigma and become a well-respected and relied-upon member of our team,” says his nominator, Drew Hoffman, company vice president.

Eighmy has had the opportunity to receive training in Kaizen events, 2-Second Lean, as well as Kata, and learn how to effectively implement each. He has also been an active member of Precision Machined Products Association (PMPA), having served previously on a marketing committee and attending various national technical conferences.

“I have been lucky to have had great mentorship and experience working in various roles in the manufacturing industry,” he says. “My long-term aspirations are to continue to grow American Turned Products and lead the company to success in future generations.”

Morgan Miller, Continuous Improvement Coordinator, C&A Tool

As continuous improvement coordinator, Morgan Miller excels at identifying and organizing necessary projects within C&A Tool (Churubusco, Indiana) and encouraging team members to see things from a different perspective.

“I get to work with amazing people to understand processes, identify problems and develop solutions,” Morgan Miller says.

These projects cover all facets of the company’ operations, span across three facilities and impact almost 700 employees. She has garnered support from employees to identify and implement new ways of doing things at a company that has been in business for over 50 years.

“In the short time that she has been with the company, she has made the single largest positive impact that I have seen in 12 years here,” says her nominator, Ryan Miller, an engineer at the company. “I have never seen her falter under the stress of all she has to keep track of, and she is the most organized person I have ever had the pleasure to work with.”

Before Miller came to the company last year, departments were functioning in silos, resulting in multiple groups working unknowingly on similar projects. With the help from her teams and support from leadership, she has developed a communication structure to ensure improvement projects are launched and implemented successfully.

“I get to work with amazing people to understand processes, identify problems and develop solutions,” Miller says. “I aspire to be a leader who empowers individuals and teams to perform at their highest level, so we can continue to be the best at what we do.”

Her nominator adds that her accomplishments so far at the company have been inspiring.

Travis Donaldson, Project Manager, Donmac Precision Machining Inc.

Although Travis Donaldson joined the team at Donmac Precision Machining Inc. (Foxboro, Ontario, Canada) – his parents’ company – only last year as a full-time employee, he knows the business well. He grew up learning the basics of production machining, but decided to go to college to become an

“I came on to design and build the new plant,” Travis Donaldson says. “Two years and many projects later, I can’t imagine working anywhere else.”

electrician instead of working at the family business. But, after using his education to work with emergency power systems, he chose to go back to Donmac.

“The family business was always in the back of my mind and when it outgrew the original property, I found my calling,” Donaldson says. “I came on to design and build the new plant. Two years and many projects later, I can’t imagine working anywhere else.”

Since returning to the family business, Donaldson has initiated the 5S program, spearheaded major changes to inspection (including coordinating measuring machine programing) and has played a significant role in automating three new programs in a short amount of time. He works with the employees to find best solutions for production advancements, including anything from a simple improvement to a major overhaul of the production cell.

“Travis has taken on working with the customers, engineering departments and quality control to streamline production,” says his nominator, Jamie Smith, production manager. “He makes time to ensure employees have the knowledge and tools to proceed with the job at hand.

“I am very excited about the future and culture of Donmac with Travis becoming a stronger team leader every day. As the business moves forward in expanding with new employees and technology, he will be a huge asset with his ability to listen, learn and teach.”

Gary Sweeney, Operations Manager, Everett Industries

As operations manager of Everett Industries (Warren, Ohio), Gary Sweeney is leading the 58-year-old company, modernizing and streamlining processes while developing new products for the next-generation workforce.

At Everett Industries, Sweeney has organically developed engineering and product development systems and transformed them into scalable, reliable and efficient methods.

Sweeney began his manufacturing career as a non-college-educated machine tool builder. He worked as a mechanical developer at a robotics company, prototyping and field testing autonomous vehicles designed for infrastructure inspection. He then worked for Drake Manufacturing, a manufacturer of thread grinders, where he held quality and methods manager roles and eventually became the production manager. He also earned his executive master’s degree from Case Western Reserve University while employed at Drake.

At Everett, a manufacturer of abrasive cut-off machines and wheels where Sweeney has been employed for 2 ½ years, he has organically developed engineering and product development systems and transformed them into scalable, reliable and efficient methods.

“He has learned aluminum casting, molds, tooling and heat treating to secure the company’s supply chain,” says his nominator, President James Vosmik. “He has inventoried, qualified and then improved our fixtures for machining the castings. He has taught himself the Mazatrol CNC control (circa 1992) and is verifying and qualifying all the programs and tooling for machining shafts and wheel flanges. This is in addition to developing economic order quantity models for all our wheel and part inventory after building detailed bill of materials for all our catalog saws.”

Sweeney also served as a trooper with the Ohio State Highway Patrol.

Erica Bonen, Quality Engineer, Galion LLC

Being able to help others develop and learn by sharing her knowledge is what Erica Bonen loves best about her job as quality engineer at Galion LLC (Galion, Ohio). She says the company — a cold forming, screw machining and small CNC machining business — has always encouraged her in her quest to

Erica Bonen develops controlled inspection documents based on internal processes and customer requirements.

grow and develop professionally, so she would like to do the same for others.

She admits that she makes mistakes, but learns from them. “Adaptability is vital for healthy change,” she says. Bonen displays this quality every day with the other members of the Galion team. That ability to adapt is one of her greatest strengths, next to being organized and her uncanny ability to prioritize her tasks.

In her position, she develops controlled inspection documents based on internal processes and customer requirements, ensuring clear and accurate inspection criteria that offers the highest quality product to customers. Bonen also generates first article acceptance test plans in accordance with customer specifications for new and existing products.

In her 12 years at the company, she started as a general laborer, then moved to a final quality inspector and then onto quality technician, where she received Galion’s Employee of the Year Award in 2017. In 2018, Bonen was promoted to quality engineer and is a strong candidate to directly replace Galion’s current senior quality engineer upon his retirement.

Bonen, a mother of two children, says her aspirations include mentoring individuals who have an interest in the automotive, commercial and defense industries and aiding those individuals in reaching their goals.

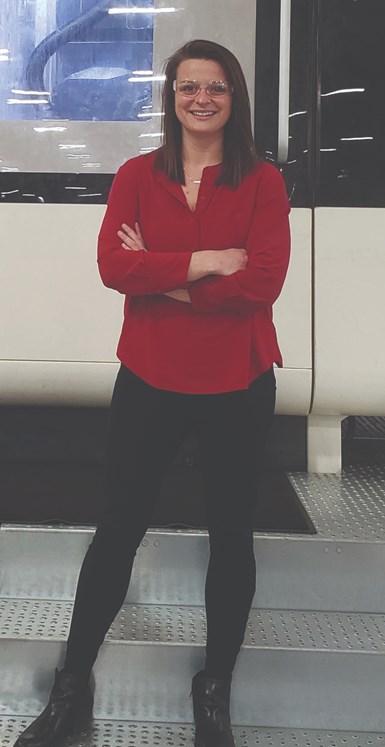

Renee Schroeder, Vice President of Operations, Smith and Richardson Inc.

Often referred to as the heart and soul of Smith and Richardson Inc. (Geneva, Illinois), Renee Schroeder, vice president of operations, has worked to help the company grow its business since she began her career there after graduating from Northern Illinois University.

“I started in an accounting role, which allowed me to learn about the whole company and all aspects of manufacturing,” she says. “I have come to love manufacturing and what it stands for. Manufacturing has become more than just a career, it’s a passion.”

Rich Hoster, president of the company and her nominator, says he relies on Schroeder’s dedication to her job and her ability to make decisions that assist with cultivating the business. “She has become a leader and has the respect of

“I have come to love manufacturing and what it stands for,” Renee Schroeder says. “Manufacturing has become more than just a career, it’s a passion.”

the entire organization as well as the respect of many of our large customers with whom she has significant contact,” he says.

Schroeder, mother of three young girls, says, “I have been very fortunate to have Rich Hoster as my mentor who has taught me what it means to be a leader. My goal is to continue to share manufacturing with the younger generation so they too can find passion from it.”

Hoster adds that Schroeder is an awesome role model for all working mothers and does an amazing job with her work/life balance. He says she is humble, as she hardly takes credit for all the positive contributions she has made to the organization. “She is impressive,” he adds.

Cassandra Haupers, Vice President of Operations, Swiss Precision Machining Inc.

Cassandra Haupers’ daily refrain is, “We hold ourselves to the absolute highest of standards.” This vice president of operations at Swiss Precision Machining Inc. (Wheeling, Illinois) consistently reminds employees of the purpose of their work: “We are machining the parts this world needs to be at its best for tomorrow,” she says.

Haupers knows the ins and outs of the business, especially because she began

Cassandra Haupers with her father. “As the future owner, it’s my responsibility to garner the respect of my peers and to lead a prosperous company. To do so, I must learn from the past and innovate for the future,” Haupers says.

her career on the shop floor and learned how to operate, set up and program lathes and milling centers. After mastering the machines, she moved into engineering, quality control and sales areas of the business.

Although she isn’t stationed in front of a machine anymore, Haupers loves to be on the shop floor to stay in regular communication with the machinists so she can learn about their successes, challenges and ideas for the future. Her connectedness with the shop floor makes her good at investing in the latest technology needed.

“With her exemplary leadership and determination to succeed, Cassie is a positive role model for everyone at SPM, but especially for women in manufacturing,” says her nominator, Georgia Joseph, digital director at Concept Co. “She believes in her people and is quick to let them know that they can achieve anything.”

“Looking to my future in manufacturing, I not only want to meet family expectations, I want to surpass them,” Haupers says. “My father has owned this company since 1979. As the future owner, it’s my responsibility to garner the respect of my peers and to lead a prosperous company. To do so, I must learn from the past and innovate for the future.”

Joshua Tinney, Operations Manager, Tinney Tool and Machine Co. Inc.

Growing up in his family’s machine shop, Tinney Tool and Machine Co. Inc. (Belleville, Illinois), Joshua Tinney didn’t always feel called to a manufacturing career. In fact, Tinney received a bachelor’s degree in religious education and served as a youth pastor in California before he began a full-time position with the family company in 2013. This is when he and his wife moved back home and he stepped up to help the business.

Tinney’s readiness to adapt and develop innovative solutions and goals has increased companywide sales, effectiveness and efficiency. He aspires to take long-term relationships with customers seriously, while striving to help Tinney Tool stay at the forefront of manufacturing.

“Joshua consistently goes above and beyond what is needed, always looking

Joshua Tinney’s readiness to adapt and develop innovative solutions and goals has increased companywide sales, effectiveness and efficiency.

for ways to better our company, even when most of us are complacent and resistant to change,” says Karl Tinney, company president/owner and Joshua Tinney’s father and nominator. “He is effective in guiding others and wears many hats, and does it with integrity and a positive attitude. Joshua is always there to get it done. He is not afraid to experiment, take risks, fail forward and try again.”

When Tinney is not within the walls of Tinney Tool, he can often be found advocating for manufacturing. He works to get the next generation excited about manufacturing at local high schools. He also serves on the board for National Tooling and Machining Association’s St. Louis chapter.

Joshua Hardwick, Operations Leader, W.H. Bagshaw Co. Inc.

In three short years, Joshua “Josh” Hardwick has gone from having only a tech support background to CNC machinist to team leader and then on to operations leader at W.H. Bagshaw Co. Inc. (Nashua, New Hampshire). With his current position as operations leader, he supervises the safety and tech teams, and continues to grow within his role. He has completed a Loss Control Academy program and is highly involved with the internal ISO audits.

“I look forward to continuing to grow my career at W.H Bagshaw by using my leadership and troubleshooting skills to help my team accomplish anything that comes their way,” Josh Hardwick says.

Hardwick is dedicated and lives up to his position as a leader within the company. Not only does he open the shop at 4 a.m. each day and regularly works overtime as needed but he also helps his co-workers enhance their skills. “He’s first to do a ‘dirty job’ himself, but is savvy to delegate for the purpose of elevating and advancing someone else,” says his nominator, Adria Bagshaw, vice president. “He's supremely patient and has been a great resource for the other team leaders, not only answering their questions but taking the time to explain and improve their skills.”

Bagshaw adds that Hardwick has shown a great ability to synthesize information. “He conducts himself with a quiet confidence and is unflappable when an issue comes up,” she says. “Josh lives our core values: family, empowerment, courage/perseverance, ‘make it happen’.”

“I look forward to continuing to grow my career at W.H Bagshaw by using my leadership and troubleshooting skills to help my team accomplish anything that comes their way,” Hardwick says.

To watch videos about our 2020 Emerging Leaders, click on the links below:

Related Content

Emerging Leader's Problem-Solving Skills Cool Down a Hot Project

This 2023 Emerging Leader developed a product in response to a call for help from Yamaha that was a huge hit in the snowmobile industry when it hit the market in 2010. In fact, it is now a common product that most snowmobile OEMs have implemented.

Read MoreApplying a Healthy Approach to Employee Investment

Service Center Metals’ on-site health center offers its employees and their families free same-day health care and, in return, the employer is gaining many benefits including a healthier workforce and attracting potential employees.

Read MoreThe Value of Aligning Efforts to Promote Manufacturing Careers

Successfully building the next generation of manufacturers requires a team effort between employers, educators and parents. Each of these three groups has a tremendous impact on young people’s career decisions. Without the support of all three, we are unlikely to bridge the skilled labor shortage that threatens the future growth of our industry.

Read MoreGift a 3D Printer to an Employee?

Some shops have purchased inexpensive polymer 3D printers for their operations. Does it make sense to take this a step further and give (or loan) a sharp young employee one to experiment with at home? This small investment could pay off for your shop in different ways.

Read MoreRead Next

Meet Production Machining's 2019 Emerging Leaders

Production Machining has discovered a lot of young talent in the industry, and we want to share the stories of 20 of these young leaders with you.

Read MoreHow Champions Can Develop a Thriving Workforce

Having a workforce development champion in your shop is more critical now than ever before. Here are five techniques your champion can apply to attract and retain new talent.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More