Mill-Turn Saves Time and Meets Market Demands

The Siemens Norwood Large Drives motor factory reduced setup times and met customer demand by purchasing a WFL M80 mill-turn capable of fluting, a process that can remove 60 percent more material with each pass than existing machines’ welding capabilities.

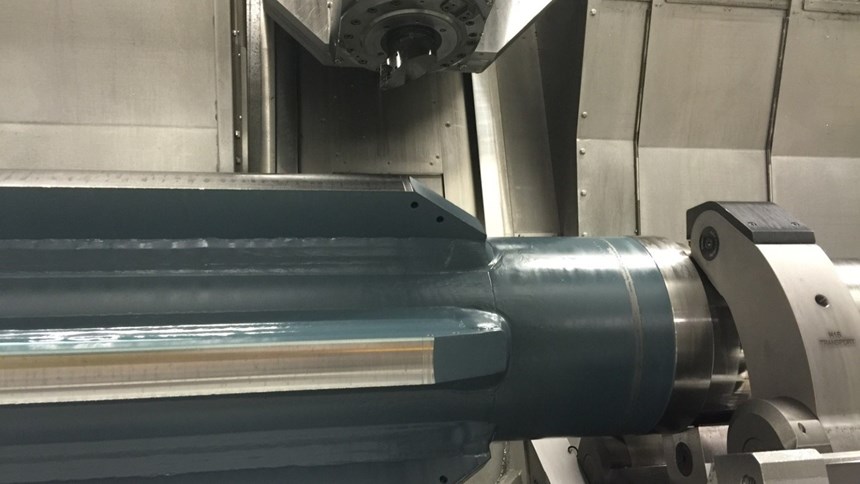

The Siemens Large Drives motor factory in Norwood, Ohio, recently upgraded its manufacturing capabilities at the 117-year-old facility by purchasing a WFL MillTurn Technologies M80 mill-turn. The CNC machine will aid in the manufacturing of steel rotor shafts to be used in Above NEMA electric motors and, in turn, enable Siemens Norwood to fill a major gap in the market and meet customers’ needs.

Compared with many of the company’s existing machines that are more than 30 years old and have required increased maintenance over their lifetime, this new machine saves time and uses less manpower.

When shafts arrive in the facility as raw material, several modifications, including full-penetration welding, must be made before they can withstand the extreme torques inside a motor. The welding procedure for full-penetration welds requires three or four weeks of time-intensive, internal and external labor and quality checking. Almost all shafts require turning, milling, drilling and tapping procedures, which were historically performed on separate machines. The transitioning between those multiple machines adds setup time, creates transportation waste and increases risk of scheduling conflicts.

However, with the M80 mill-turn, all of those procedures can be performed sequentially in a faster time and with less supervision. The CNC machine also eliminates former waste and potential risks in a new process called “fluting.” Fluting is subtractive manufacturing that mills out material from a larger starting radius versus the previous additive manufacturing that welds more material from a smaller radius. This process takes less than one day versus several weeks in the previous process.

The need for this new CNC machine follows the recent market change that has required larger frame sizes, higher speeds and, thus, larger and stiffer rotor shafts. Traditionally, the volume for larger rotor shafts—the size which is best suited to run on the M80 mill-turn—has been low, but increased customer use of variable frequency drives has shifted the industrial motor business to invest in new manufacturing technology.

The WFL M80 mill-turn is 16 feet wide, 13 feet tall and 52 feet long, weighing in at 58 tons. In fact, the machine is so large that it could not fit through the existing door to the facility, so part of the garage frame had to be removed and then replaced once the machine was inside.

Once set up, the Norwood team was faced with learning a WFL coding language to operate the new machine, requiring intensive training to overcome a steep learning curve. Not only is the programming new to Norwood, but the logistics of installation and the release to production demanded constant cross-functional teamwork. There were several weeks of preparation and manual labor to finish the installation, followed by machine calibration and training that had to take place before the first production part was created and released.

Regardless of the obstacles that came with purchasing the machine, the positives far outweigh the negatives. The new CNC machine uses 72 tool heads, each of which is automatically selected and calibrated by the internal tool measuring system and software, with a Siemens Sinumerik 840D CNC controller on the machine, as well. The mill-turn can do more in less time, removing 60 percent more material with each pass compared with the existing machines. In addition, the length of the capable shafts for CNC milling has increased to 220 inches, as compared with the previous machine’s 117-inch maximum limit. All of these aspects make the new mill-turn a highly valued asset to Norwood’s rotor manufacturing process.

The implementation of the WFL M80 has been a success. With it, Siemens Norwood aims to significantly improve its lead time and reduce manufacturing costs, as well as gain valuable experience for other manufacturing equipment coming to the facility in the future.

Related Content

Nomura DS Showcases Turning and Milling Machines Engineered with Excellence

Gosiger offers the comprehensive line of Nomura DS machine tools at competitive prices.

Read MoreGetting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

Read MoreA Mill-Turn’s Value for Machining Micro Gears

This leading manufacturer of non-lubricated robotic gears uses a seven-axis turn-mill to machine components from “amorphous” metals such as bulk metallic glasses.

Read MoreChoosing the Right Machine for Turned and Milled Medical Parts

The medical market is known for exceptionally tight tolerances and difficult materials, which means that selecting the proper machine is necessary to ensure a job is profitable.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)