New CAM Software Helps Shop Take on More Challenges

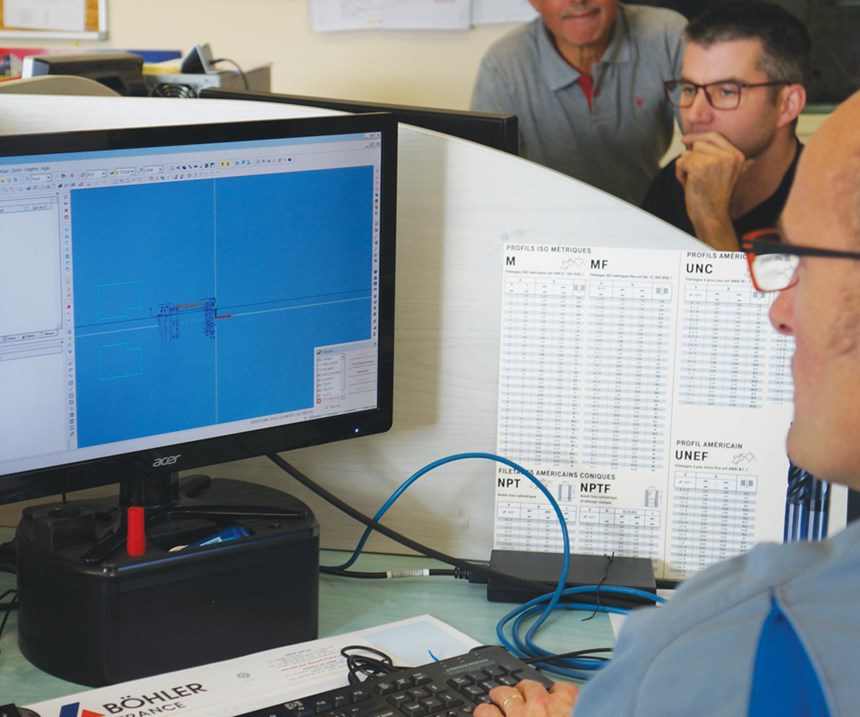

Robin Technologies selected Esprit by DP Technology to meet the high demands necessary to take on more complex projects.

When your customers are in multiple industries and demand many types of machining processes to complete their orders, you need to be as flexible as possible, and this means your machines as well as your attitude. The staff at Robin Technologies (Chantonay, France) understood this was their situation not long ago. The company sits in the Pays de Loire region, which is the third largest industrial region of France and home to major manufacturing companies such as Airbus, Total and the Saint Nazaire shipyards. Robin Technologies became a contractor to these and other manufacturers, providing precision machining services to manufacture aeronautical maintenance tools, dies for the agriculture/food industry, gearbox parts for the automotive industry and various parts for the robotics and cosmetics industries.

Such customer diversity demanded higher multitasking skills than what the company originally had to offer. Therefore, management selected Esprit by DP Technology to meet these demands necessary to take on more complex projects. It’s important to them that the company continuously invests in the latest CNC machines and new technologies.

Tony Jourdain, production manager, says, “My priority is to give our teams everything they need to be as productive as possible, including the latest production technologies and training in equipment and programming. The right CAM solution is a key part of achieving these goals.”

Founded in 1980 by Damien Robin, Robin Technologies focused for several decades on manufacturing molds. After the mold market became less profitable because of global competition, the company began turned to wire EDM and two- to five-axis milling to subcontract machining of complex parts. The company currently uses 15 numerically controlled machine tools, mainly ONA and Mazak brands.

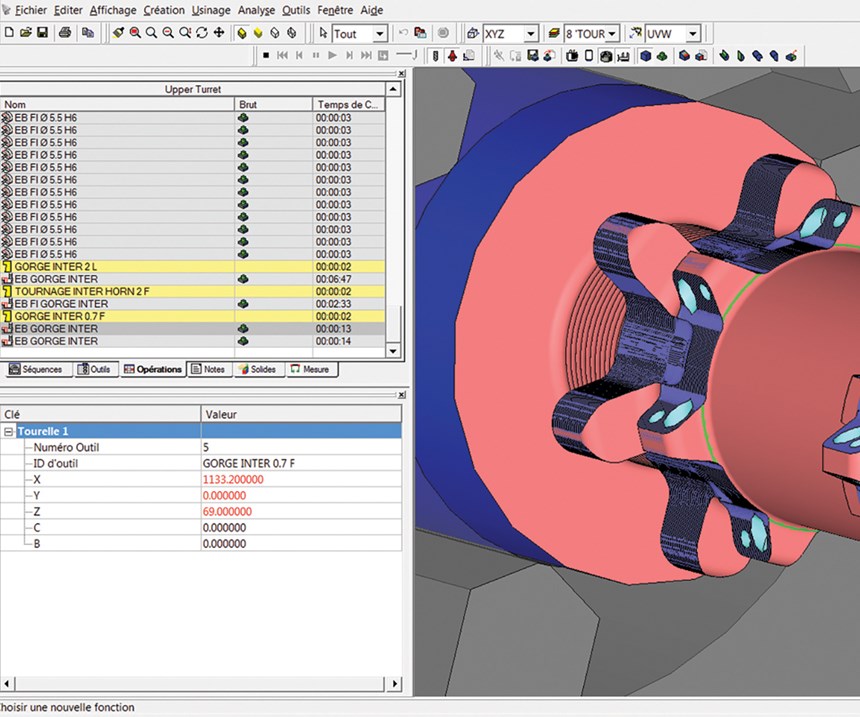

Robin Technologies selected Esprit as its CAM provider because it offers functionality in milling, turning, multitasking, wire EDM, Swiss-type and B-axis machines, which enable the company to run its entire machine shop using only one CAM software package. After purchasing it, the company successfully took the leap to five-axis and 3D machining, a strategic choice that enables Robin Technologies to meet the demands of servicing the multiple industries.

“Esprit helped us improve our multitasking skills on our Mazak Integrex machines, making it possible to take on more complex projects and expand our manufacturing capabilities,” says Frédéric Allard, turning-milling programmer for Robin Technologies.

Soon after Robin Technologies implemented its new CAM software, Airbus consulted with the company about producing a complex gage that could only be machined using five-axis milling. With the help of their sophisticated machine tools and Esprit CAM, the Robin Technologies team delivered the part on time and met the quality and cost requirements of the customer.

The software allowed the company to minimize configurations, tools, maintenance and time not devoted to cutting on its machine tools, each of which includes two turning spindles for all-in-one machining and a lower turret.

The CAM software’s postprocessors, according to Robin Technologies, are another strength. The postprocessors are tested and certified by the machine tool manufacturer and are open source so they can easily be modified by the user. “It gives us great flexibility,” says Sébastien Giraud, head of EDM. “Currently, we have three EDM machines of different brands. The postprocessor provided lets me move programs from one machine to another without difficulty.”

Esprit also enables the company to maximize the capabilities of its ONA wire EDM machines. It has helped the company to produce sophisticated parts on its ONA four-axis wire EDM machines.

Not only is the software reliable with impressive functionality, the customer support is as well, according to Damien Roure, head of ONA France. He says the Esprit support teams are attentive and react quickly to problems and those of their customers. Having a good relationship with a software provider is critical, and Robin Technologies has found that in Esprit/DP Technology.

This strong relationship has also prompted new learning opportunities for Robin Technologies. Advanced training courses from Esprit, for example, have enabled the company’s programmers to accept even more difficult challenges. Robin Technologies was recently contracted to program a competitive mountain bike wheel hub that required milling and turning many complex faces with the most complicated operations being the Z-level roughing and composite spiral finishing. The software support team helped programmers to further develop their skills and program the part in one day.

By adapting its company strategy to changing market conditions and choosing reliable partners such as Esprit CAM, Robin Technologies provides its customers with quality parts at attractive prices. Implementing this flexible approach has enabled the company to succeed in the highly competitive contract machining marketplace.

For more information from Robin Technologies, visit robin-technologies.com.

Related Content

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAD/CAM system. Here’s how the company succeeded despite the newness of it all.

Read MoreTech College Alum Returns to Teach CAD/CAM at Alma Mater

New part programming developments continue to be added to the Tri-County Technical College curriculum and solutions for Swiss-type lathes might soon be included.

Read MoreMastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

Read MorePrecision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

Read MoreRead Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)