Oil/Coolant Mist Collector Addresses Efficiency Challenges

These oil/coolant mist collectors can contribute to employee safety and a better work environment all around.

Among the reasons young people give for not choosing a career in manufacturing is the perception that factories are dirty, unhealthy places to work. In truth, the majority of today’s CNC machine shop owners take pride in providing a clean, safe workplace for their employees, and they make significant investments in health and safety-related equipment. One of the most challenging issues is mist and smoke pollution created by the oil-based, synthetic or emulsion-type coolants used by modern CNC machine tools.

If left unabated, oil/coolant mist emitted by machine tools hangs in the air and eventually settles on all surfaces, including machines, floors and people. Breathing these pollutants can cause serious respiratory problems; aggravate existing breathing conditions; irritate the eyes, nose and throat; and cause skin irritation. These issues can lead to employee health problems and related absenteeism while slick, oil-covered floors present the risk of injuries from falls. All of these concerns create potential liabilities for the shop owners and problems with OSHA or other regulatory agencies.

Even high-efficiency factory HVAC systems typically can’t keep the workplace free of these contaminants, which is why many shops invest in oil/coolant mist collection devices. The technologies behind the three most common types of oil mist collectors are electrostatic, centrifugal and multi-stage media. Each type has unique characteristics that impact efficiency and reliability in different ways.

Electrostatic Oil/Coolant Mist Collectors

The electrostatic technology used in some oil/coolant mist collectors was originally designed to eliminate dust and other particulates in air handling systems and to remove dry smoke. The technology is effective for these purposes. Unfortunately, when continually exposed to oil/coolant mist, the system’s cells can become coated by layers of liquid, reducing their efficiency. Therefore, users must regularly clean the cells, usually on a monthly basis. Unfortunately, every time the cells are cleaned they lose some of their ability to remove the oil/coolant mist. The result is reduced efficiency and increasingly shorter time between cleaning cycles. Additionally, the costly tungsten ionizer wires on the bottom of the electrostatic cells must be periodically replaced (usually about every two years).

Another potential drawback of electrostatic cells is that they typically operate at a lower voltage setting for applications involving water-based coolants. This adjustment is made to alleviate annoying popping and crackling noises caused by the difference in the polarity between water coolants and oil. Operating at this lower input voltage further decreases overall efficiency. Electrostatic units also emit ozone that can reach substantial levels in multi-unit installations, thus creating an additional air quality issue.

Centrifugal Oil/Coolant Mist Collectors

More than 35 years old, the centrifugal design is the oldest oil/coolant mist collection technology on the market. As the name implies, this type depends on centrifugal force to thrust impurities outward from the center of the device. When used to collect oil/coolant mist, the unit’s sponge-foam filtering pads quickly become saturated. This condition reduces airflow and the amount of impurities that can be processed, so efficiency drops off and mist escapes into the air from the machine enclosure.

Because the centrifugal cage impeller is not a true fan, the air curve cannot be measured to determine exactly how much air is flowing through the unit, so the efficiency of the system cannot be effectively monitored. Other disadvantages are the high amount of energy required to turn the heavy centrifugal components, and the resultant noise that is a function of the pads becoming unevenly clogged. These clogged pads can create an out of balance condition as the unit rotates, often developing significant vibration that may be transferred to the machine tool, resulting in part quality issues.

Multi-Stage Media, Hybrid Oil/Coolant Mist Collectors

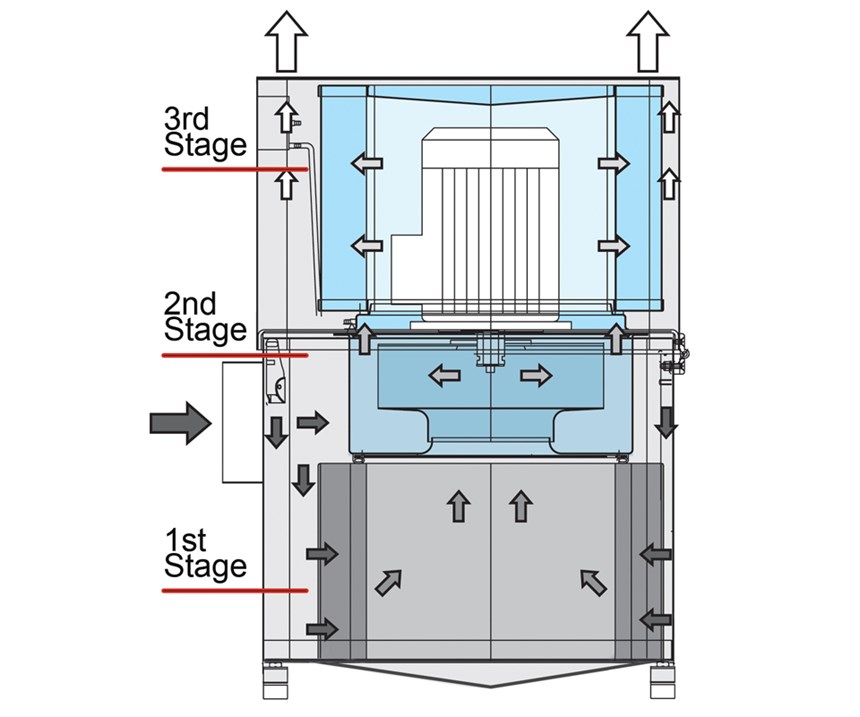

Multi-stage oil mist collectors use a three-stage system that consists of an initial pre-filtration cartridge, a cyclonic separation chamber, and a final stage filter to achieve as high as 99-percent filtration and residual oil mist concentration of only 0.2 mg/m3 (milligrams per cubic meter). LNS oil mist collectors use this multi-stage design to accommodate all machine types and processes that use water-soluble, synthetic or neat oil coolants.

The multi-stage design is engineered to eliminate the maintenance requirements of electrostatic oil mist collectors, as well as the noise and vibration problems associated with centrifugal type units. It can also reduce energy consumption and provide verifiable, continuous filtration efficiency.

How Each Stage Works

As oil mist is drawn into the collector, it passes through a multi-layered pre-filtration cartridge. This cartridge consists of three filtering layers that remove solid particulates and entrain bulk liquids. At the same time, it agglomerates finer mist particles into larger ones. Overall efficiency at this stage is 92 percent.

In the second stage, the oil mist droplets accumulated in stage one are further reduced by means of inertial impaction, whereby small dust particles and liquid droplets impact a deflecting surface—in this case, a special impeller that creates a cyclonic effect. These particles are forced to a cylinder wall where they coalesce and are then captured.

The third stage uses a high-surface-area cartridge media filter to remove any remaining oil mist. This filter removes 99 percent of oil mist, exceeding OSHA and NIOSH standards. Users can also add an optional fourth-stage HEPA filter that removes 99.97 percent of cutting oil smoke particles.

An integrated pressure gage monitors the condition of the stage-three filter by measuring airflow. Routine maintenance consists of replacing the long-life filters, which typically maintain efficiency for 3,000 to 4,000 hours. Average time required to replace a filter is five minutes.

Using a laser particle counter, users can instantly read the overall efficiency of LNS multi-stage oil mist collectors as expressed in milligrams per cubic meter (mg/m3). Shops fully equipped with these oil mist collectors typically achieve readings of 0.2 mg/m3.

Meeting the Shop’s Needs

CNC shops can have a variety of machine tools, so it’s important to match the machine with the appropriate oil mist collector. The WS Series has five models with airflow rates ranging from 170 to 1,250 cfm. They can be mounted directly on the machine tool or secured to a stand.

Tony Staub, owner of Staub Machine Company in Hamburg, New York, learned the differences in oil mist collector technologies through personal experience. “We consider ourselves an environmentally conscious company. But beyond that, we spend a lot of time in the shop, and I want to protect the health of my 34 employees. Through the years, we’ve tried a variety of approaches, starting with a unit that had a spinning filter. Unfortunately, it produced an annoying, droning noise that was hard to listen to all day. We tried other technologies that solved the noise problem, but each had other drawbacks. Complications included some serious maintenance issues such as repeated bearing and shaft failures, and the need to frequently change filters. Next, we tried electrostatic, collection cell and ionizer wire-based units, but they did not keep the air quality consistently good unless we constantly performed cleaning and maintenance on the units, which became a drain on our time. Our data suggests that the LNS oil mist collectors more consistently maintain our air quality standard than the other units.”

Along with the important benefits of safeguarding the health and wellness of the workforce while reducing employee absenteeism, installing multi-stage oil mist collectors can bring other advantages. Because the units release filtered air back into the shop, there is no direct venting to the outside. This design saves energy by reducing the load on the shop’s HVAC system. Mean time between planned maintenance and associated labor costs is also reduced because of the minimal time required to change filters.

Related Content

The Case for Higher-Performing Metalworking Fluids

Machine shops have the opportunity to enhance their profitability by choosing the proper metalworking fluids for each machining application.

Read MoreFluidLynx Offers Intelligent Cooling Lubricant Automation

PMTS 2023: Motorex’s FluidLynx automated fluid management system offers controllable and traceable process reliability, while better protecting workpieces and machines, and optimizing tool life.

Read MoreAutomate Coolant Management, Collect Data to Optimize Machining Operations

The future of coolant management lies in better control through automation and applying real-time data analysis and insights.

Read MoreCustom Formulations for Proper Equipment Lubrication

PMTS 2023: Engineered Lubricants manufactures custom formulations of lubricants, metalworking fluids, rust preventives and cleaners to fit customers’ specific production requirements.

Read MoreRead Next

Technologies for Chip and Coolant Management

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)