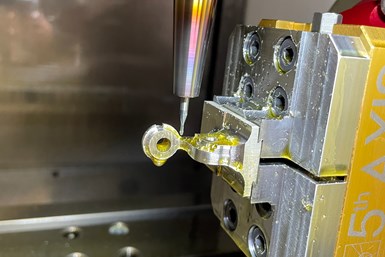

If the performance needs of a specific machining application aren’t matched by the characteristics of your choice of metalworking fluid, problems might occur. (Photo credit: PM)

Do you know what’s in your metalworking fluids?

If that sounds like a strange question, you’re not alone. Many machine shop operators have a lot to think through on a given day, and the contents of a particular metalworking fluid might not be at the top of the priorities list. Supply chain challenges spurred by the pandemic have added a layer of complexity here, too. The availability of certain fluids is not always guaranteed, which may prompt unexpected formulation changes.

But the truth is that selecting the right metalworking fluid for any given application is important, and it can have a big impact on a machine shop’s bottom dollar. Highly demanding machining applications might require a level of performance worthy of premium prices; less demanding ones may only require something more basic.

In either case, optimizing your fluid selection for every application in your shop can reduce maintenance costs associated with premature tool wear, problematic breakdowns, cross-contamination and other operational issues.

Informed metalworking fluid selection begins with a deeper understanding of different types of metalworking fluids and some of their critical performance characteristics. What’s more, close collaboration with your fluids supplier to apply the right formulations for the right applications can yield beneficial results.

Common Metalworking Formulations

First, it’s useful to understand the different types of metalworking fluids that are commonly available, along with the applications for which each is most commonly suited. Metalworking fluid types are defined by their oil and water content, and break down into four categories:

- Straight oils. Also known as neat oils, these fluids contain no water and are typically used as received. They offer reliable performance in applications that see heavy operational severity because of their excellent lubricating properties. However, their cooling properties are limited and should not be used in high-speed applications that generate high heat levels.

- Soluble oils. These fluids also do not contain any water content in their concentrates, but are intended to be mixed with water by the end user. In doing so, these fluids’ cooling properties are enhanced, generally making them well-suited for medium- to heavy-duty metalworking applications.

- Semi-synthetic. Semi-synthetics have water content within the concentrate — typically anywhere between 10-40%. Semi-synthetics will inherently provide attractive cooling and lubricating performance benefits, making them appropriate for a broad range of applications.

- Synthetic fluids. Fully synthetic metalworking fluids contain no mineral oil and usually have 50% or more water content. They are typically found in specialized metalworking applications requiring specific characteristics, including high amounts of cooling.

Common metalworking fluids include (left to right) straight oils, soluble oils, semi synthetics and synthetics. (Photo credit: Gates Engineered Lubricants)

Straight oils and soluble oils, broadly, are legacy technologies within the metalworking fluid space, but semi-synthetics are gaining significant market share. This is because they are able to provide a good balance of performance characteristics that modern machining requires, meaning they’re worth serious evaluation by any machine shop.

Critical Performance Characteristics

Consider the following scenario: You’re replacing the tool in a critical machining application roughly once per year. This is just a part of your regular maintenance schedule. The tool isn’t cheap, but product quality suffers once it reaches a certain threshold of regular wear. It’s the cost of doing business and keeping your customers happy. But there might be another factor at play: your choice of metalworking fluid.

Semi-synthetics will inherently provide attractive cooling and lubricating performance benefits.

When the performance needs of your application aren’t matched by the characteristics of your metalworking fluid, problems might occur. For example, if your selection of metalworking fluid is purely price driven without consideration for certain performance factors, you could be spending far more on tool replacement than you are saving in fluids. Here are some of the performance capabilities you should be considering when making your fluid selection:

Lubricity and cooling. These are the fundamental performance attributes required of any metalworking fluid. Lubricating properties protect your tools from metal-to-metal wear, while cooling properties help ensure the excessive heat buildup does not cause premature damage.

However, different applications have different needs. For instance, certain turning applications can generate significant amounts of heat, making cooling properties highly important. By contrast, broaching applications require higher levels of lubricating performance and more modest demands in terms of cooling, making it a good application for straight oils.

Different materials also have different requirements. Aluminum, for example, tends to generate a gummy buildup during the machining process, necessitating a fluid formulation with the right lubricating properties to mitigate problems such buildup can cause. Titanium, an extremely hard metal, requires different properties.

Considering such a range of requirements, it’s wise to seek out a fluid solution that can handle many of them. It’s here where some of today’s semi-synthetic formulations, with their balanced capabilities for both lubricating and cooling, truly shine. Such formulations might not work or may not be necessary for every application, but selecting one formulation that can deliver on a broad range of performance needs can go a long way toward reducing complexity and protecting your machines.

Longevity and flexibility. Metalworking fluids need to be changed out eventually, but good formulations will offer long-lasting performance that can help you maintain uninterrupted operations. Such formulations will resist biological deterioration and should be able to remain stable when mixed with hard water.

Additionally, a proper formulation will still offer good performance under real-world operations. Best practices might state that the fluid should remain within 2% of its original fill, but that can be a difficult if not impossible condition to meet on a busy shop floor. Ideally, your metalworking fluid will still do its job even if a technician forgets to top it off during a given shift.

Ease of use. Another consideration is how easy it is to dilute your metalworking fluids into water. Certain formulations might require a specialized mixer to enable proper solubility with water, creating an extra step that must be followed. Hopefully, your metalworking fluids will be easy to add to your machine without too much upkeep.

Corrosion performance. Galvanic corrosion, also called bimetallic corrosion, is a newly prevalent problem, as shops increasingly machine dissimilar metals in the same application. A machine handling aluminum, copper and cast iron can see accelerated corrosion in the sump. A metalworking formulation that will mitigate this corrosion will be properly formulated with this in mind. Semi-synthetic formulations provide inherently higher levels of corrosion protection, which can be enhanced with certain additives.

Irritation factors. Machine tool operators come into contact with metalworking fluids constantly, whether it’s when they are mixing them, pouring them into a machine or during some other activity. For these reasons, it’s important to vet your metalworking fluid for potential skin irritants to protect your workers.

Sustainability. An increased focus on operational sustainability is impacting every industry in every application, and metalworking fluids are no exception. As such, it can be important to evaluate what sorts of chemistries go into your choice of metalworking fluids and how they can contribute to your sustainability mission.

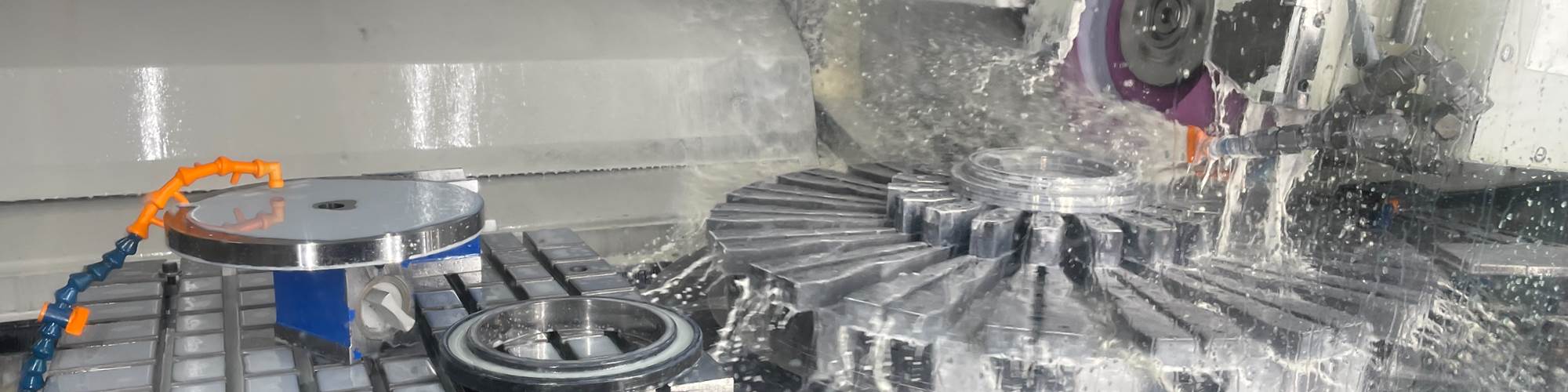

Grinding applications require just the right amount of lubricity. Too much lubricity means the wheel won’t remove any material; too little and the wheel might overload and require frequent dressing. Flushing capabilities are also critical in preventing buildup on the wheels. (Photo credit: PM)

Working with Your Fluids Suppliers

Armed with a greater working knowledge of metalworking fluids, shop owners and operators have the opportunity to collaborate with their fluid suppliers to make the most appropriate choices for any given application. Open the conversation about whether you’re using proper fluids everywhere. A good supplier should be able to tailor its recommendations to the specific needs of your operations.

It’s also important to regularly review your fluid choices — perhaps annually or potentially more frequently — based on your current business conditions. For example, maybe you’ve stopped machining steel with the same frequency and are now machining higher volumes of aluminum parts. For the reasons discussed earlier, different metals behave differently and might influence your optimized choice of metalworking fluids.

Indeed, your choice of metalworking fluids across your machine shop can make a big impact on your operational efficiency, profitability and more. It’s an important decision to get right, and staying educated can have major benefits.

About the Author

Ryan Gates

Ryan Gates is product and production manager for Gates Engineered Lubricants.

Related Content

Vomat Coolant Filters Provide Precise Temperature Control

The company’s filters ensure a continuous supply of clean oil for microtool grinding applications.

Read MoreMarubeni Citizen-Cincom Accessories Provide Faster Cycle Times

IMTS 2024: Marubeni Citizen-Cincom is showcasing a range of machining accessories designed to work intuitively with Citizen machines.

Read MoreZebra Skimmers' Coolant Systems Automate Fluid Management

PMTS 2023: The Zebra Dazzle 2 system can reportedly reduce coolant usage and CNC tooling by as much as 80%.

Read MoreFluidLynx Offers Intelligent Cooling Lubricant Automation

PMTS 2023: Motorex’s FluidLynx automated fluid management system offers controllable and traceable process reliability, while better protecting workpieces and machines, and optimizing tool life.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)