Technologies for Chip and Coolant Management

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket.

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket. Similarly, keeping clean machine coolant circulating appears to be a no-brainer. However, any manufacturer who has lost production time because of a clogged chip removal system or replaced a coolant pump that was damaged by metal debris knows better.

One reason that both of these processes have become more challenging in recent years is the proliferation of multitasking machine tools. Manufacturers are doing all they can to produce quality parts more efficiently so they can successfully compete in a crowded global marketplace. This means reducing the amount of operator time invested in setting up each machine’s dedicated process and moving workpieces from one machine to another. By using multitasking machining centers that perform a number of operations, manufacturers significantly reduce time, labor and fixture costs.

Lights-out manufacturing and unattended operation, despite the boost they can lend to productivity, present yet another significant issue. With no one in the plant to deal with chip-related bottlenecks or coolant problems, the chip removal and coolant management systems must perform flawlessly and efficiently. Conveyor discharge must be high enough to dispose of chips over a long period of time, and the coolant tank must remain clean so the flow of coolant will not be interrupted.

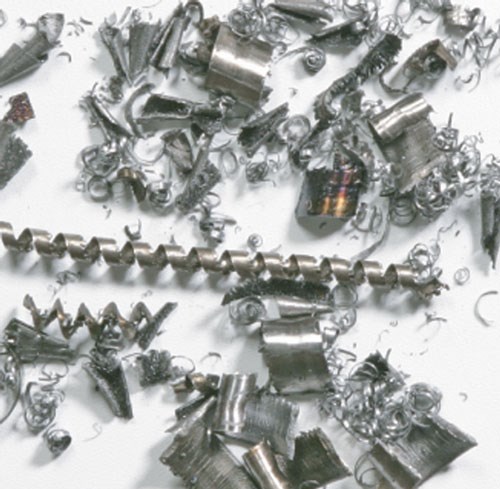

When multifunction machine tools combine such operations as milling, drilling, turning and grinding, one challenge is dealing with the variety of chip types created, each of which has its own characteristics that impact chip removal. For example, turning a part may produce stringy chips. That same part may then undergo extensive milling, which creates a combination of large and very small chips. Detail milling may follow, creating even tinier chips. In many of these cases, a large amount of coolant flow is necessary for optimum performance and to reduce tool wear. Because the smaller chips tend to remain suspended in the fast moving fluid current, a conventional conveyor with a coarse filter will allow these fine chips to wash into the coolant sump, thus causing excessive maintenance, possible damage and coolant waste. All of these factors translate into lost productivity and increased operating costs.

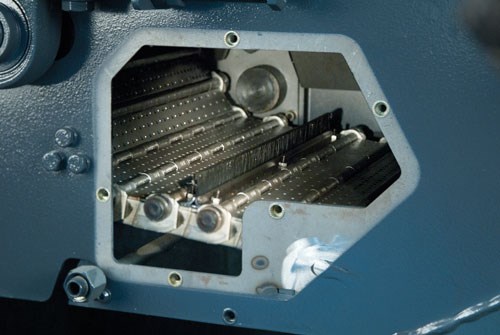

To address these concerns, LNS developed the Turbo MH series of filtering chip conveyors. These systems are designed to fit standard coolant sumps and handle virtually all chip materials and shapes. The design employs a hinge belt to remove the larger chips and filtering boxes that remove any smaller chips from the coolant, to either 500 or 250 microns, before returning the fluid to the coolant sump. In developing this filtration system, significant effort went into making the filtering boxes self-cleaning for trouble-free operation. To further minimize maintenance, the system also uses internal, fixed brushes that scrape off any remaining material.

High pressure coolant systems, such as the LNS PowerStream, help optimize productivity by preventing chips from accumulating within the machining area where they can disrupt the machine tool’s internal movements. In addition to allowing higher machining speeds, high pressure systems break up long, stringy chips so they are easier to convey. PowerStream VP gives users the ability to program variable pressure outlets to deliver as much as 2,000 psi of filtered coolant precisely where it is needed and to instantly shut off coolant flow when it is not required. It is also designed to interface via e-Connect (the LNS-developed Ethernet communications system) with the machine tool controller to automatically provide optimum coolant spray in response to changing requirements or machining variables.

Lights-out manufacturing also requires coolant that remains free of way and hydraulic fixturing oil, which can reduce coolant efficiency and, thus, tool life (the use of clean coolant can lead to as much as 25 percent higher tool life versus contaminated coolant). To combat this problem, LNS developed the PhaSep tramp oil removal system that eliminates tramp oil droplets as small as 20 microns from machine coolant, returning fluid that is 99 percent free of contaminated oil to the machine sump. A tri-ball float captures tramp oil as it accumulates on the surface of the coolant. The oil then moves through steel coalescing plates that remove the tramp oil and send it to a holding tank for disposal while clean coolant is gravity fed back into the machine sump.

An added benefit of tramp oil removal is a healthier environment for machine operators. Dirty coolant breeds anaerobic bacteria that are a major cause of dermatitis. Removing tramp oil and aerating the coolant prevents bacterial growth.

Another health and safety concern is the amount of oil mist created by high pressure coolant that permeates the air and coats floors and other surfaces within the manufacturing facility. LNS Fox mist collectors are designed to remove oil mist from the machine and return the liquid to the coolant sump, thus providing a healthier environment and reducing coolant costs. These units have a three-stage mechanical filtering system and an optional HEPA module to remove smoke.

Clearly, chip removal and coolant management that can help manufacturers maximize productivity are much more complex than they appear. As machine tools continue to become more sophisticated and multifunctioning, chip and coolant management technology will continue to evolve to meet the common goal of increased productivity and profitability for manufacturers.

Related Content

When to Use a Diaphragm Chuck

The accuracy and repeatability of these chucks make them well suited for a number of workholding applications, including turning and grinding.

Read MoreThe Value of Auto Adjust Magazine Bar Feeders

This bar feeder is designed to offer the flexibility to enable CNC turning centers to perform short-run work that would otherwise require frequent setups over a range of barstock diameters.

Read MoreVideo Tech Brief: Bar Feeder Technology Optimized for Swiss-Types

This bar feeder design is said to offer high guidance quality with minimum vibration and noise development for sliding-headstock machines.

Read MoreWhat’s the Right Bar Feeder for Your Machine Shop?

Machine shops likely have questions about what type of bar feeder makes most sense for their operational needs. One or more of these four might be floating around in your head.

Read MoreRead Next

Successful Untended Operation

Machine tool accessories can make or break untended operation.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)