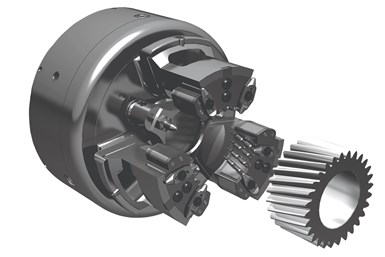

Diaphragm chucks were initially developed to reduce a bore-grinding process that was typically required after a gear is heat treated. (Photo credits: SMW Autoblok)

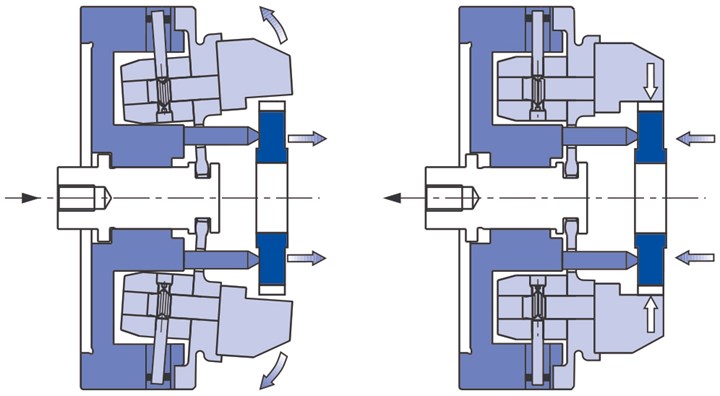

Larry Robbins, president-commercial division for SMW Autoblok, says a diaphragm chuck for a turning center functions similarly to a human’s diaphragm that contracts and retracts to draw or “suction” air into our lungs. He says unlike standard chucks that rely on the wedge and master jaw linkage for clamping, a diaphragm chuck applies the principle of elastic deformation in expanding, contracting and using resistance to hold workpieces in place. Because diaphragm chucks don’t have sliding components, they don’t require lubrication and offer a more consistent grip force repeating to within 10 microns.

Robbins explains that the accuracy and repeatability of these chucks make them well suited for a number of workholding applications, including:

- Hard turning of gears. After gears are machined and then heat treated, manufacturers typically would grind each gear’s bore to ensure it is true to the tooth form pitch line. The centering accuracy of the diaphragm chuck, however, enables manufacturers to eliminate this grinding process, reducing cost and production time. In fact, the diaphragm chuck was originally developed for this specific application.

- Centering accuracy for secondary operations. For more efficient turning, shops often use hard, serrated jaws to clamp raw material in the first turning operation. Using a diaphragm chuck for the second operation offers repeatable centering accuracy when clamping onto a part’s machined surface.

- Gears with thin walls. Diaphragm chucks typically are not recommended for thin-walled applications due to workpiece deformation that could be caused by the clamping forces.

Diaphragm chucks for turning centers apply the principle of elastic deformation in expanding, contracting and using resistance to hold workpieces in place.

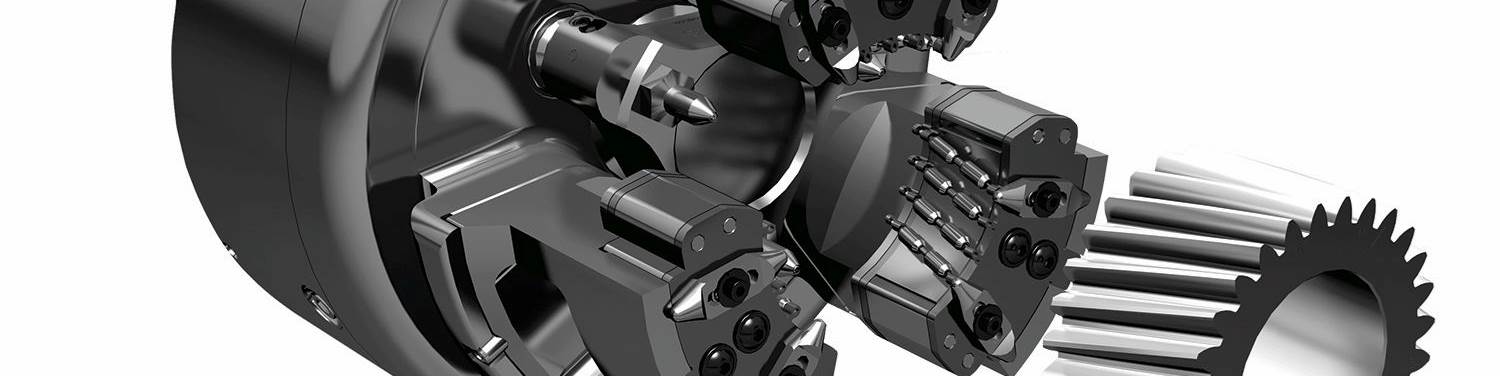

The SMW Autoblok Proofline-sealed D-Kombi diaphragm chuck provides radial centering and clamping of the workpiece in conjunction with swing clamps for axial clamping (in addition to the diaphragm clamping force). By distributing the forces axially across the part, the workpiece is less likely to be deformed radially. It also offers the ability to swap jaws in minutes and provide a center locator, creating a Z-axis plane to adjust for gear height and diameter variations. These features allow for overall increased productivity, in addition to the accurate, reliable and repeatable nature of the diaphragm chuck itself.

A diaphragm chuck uses elastic deformation in expanding, contracting and using resistance to hold workpieces in place.

The company offers other diaphragm chucks as well. Giving precision turning, grinding or milling operations a superior final finish, the D-Plus chuck is well suited for shaft-type workpieces, such as input and output shafts, or any operation where sub-micron accuracy is mandatory, Robbins explains.

In addition, the D-Vario is a quick-jaw-change diaphragm chuck specifically made for the grinding of gears. Robbins notes that speed is not achieved at the expense of quality, however, with micrometer fine adjustment of the center line makes high precision grinding possible.

Related Content

-

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

-

CNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

.png;maxWidth=300;quality=90)