(Photo credit: Ceratizit)

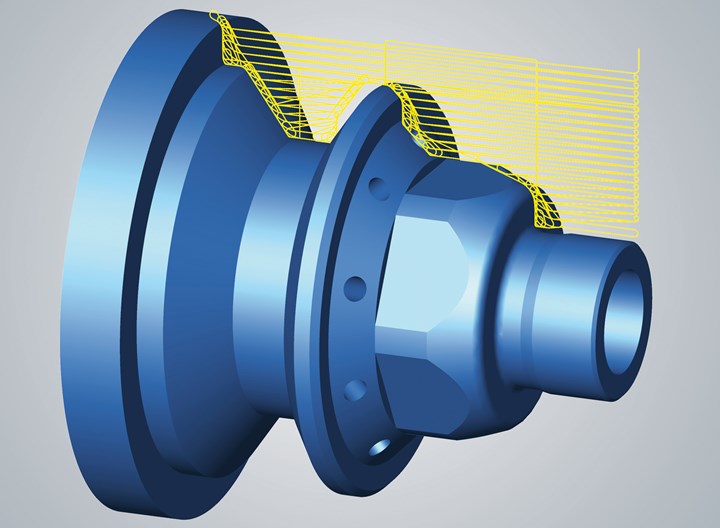

Trochoidal turning is based on a machining strategy in which tool paths and the tool entry and exit movements are optimized to maximize material removal rates. Thanks to the simultaneous use of different machine tool axes in combination with round, indexable inserts, this machining approach can offer many advantages compared to conventional turning. Trochoidal turning strategies combined with latest CAM software can enable shops to significantly increase efficiency and output in a wide range of roughing operations.

Trochoidal turning is separated into two strategies — basic operations performed on conventional turning machines and simultaneous operations performed on multitasking machines with B-axis movement. These turning strategies echo the concepts of trochoidal milling which combines a spiraling cutting path with straight-ahead tool motion.

Trochoidal milling also employs light radial depths of cut, large axial depths, and fast feed rates and cutting speeds. In addition to high material removal rates, it offers low radial cutting forces and reduced vibration while maintaining the required chip loads on tool cutting edges. The results are increased productivity, shorter cycle times, longer tool life and reduced wear on the machine tool.

Similarly, trochoidal turning features lighter depths of cut, higher feeds and faster cutting speeds than conventional turning, but uses standard round turning inserts that increase toolpath flexibility and permit smooth entry and exit from the workpiece. With trochoidal turning, the insert is always in the cut, eliminating the time lost returning to a set point after every pass. In addition, trochoidal turning performs longitudinal and face turning as well as radial and axial grooving.

These light cuts and reduced cutting forces are advantageous when cutting difficult-to-machine materials such as stainless steels and nickel- and titanium-based alloys. Because it can be possible to employ high feed rates to affect chip breaking, the approach is also beneficial when turning soft yet tough, ductile materials that normally produce long chips that endanger operators and wrap around the workpiece and tool.

Recognizing the productivity advantages of trochoidal turning, CAM software provider Open Mind Technologies engineered HyperMill software to expedite trochoidal turning on conventional CNC turning machines. The software is said to enable intuitive programing of trochoidal turning on standard three-axis turning machines. However, using a multitasking machine with B-axis capability enables a shop to take full benefit of trochoidal turning strategies.

Multitasking machines with B-axis capability can enable shops to take full benefit of trochoidal turning strategies.

Programming that additional axis is somewhat more complex than a three-axis scenario, but the rotating B axis provides greater accessibility when turning complex parts and is therefore faster and more efficient. The round inserts combined with light depths of cut and the ability to rotate/swivel the cutting tool relative to the workpiece axis effectively creates more cutting edges and extends tool life. The software also optimizes tool paths to prevent sudden loads on the inserts. Using the rotary B axis to freely move the insert in space also promotes uniform movement of machine tool components that reduces stress on the machine and prevents collisions.

Process Details

Feed rates for trochoidal turning relative to conventional turning are three to five times faster and depths of cut are 20 to 30% less. And, while doubling the material removal rate for turning potentially reduces cycle time by 50%, cycle time savings can be as much as 70% for grooving applications.

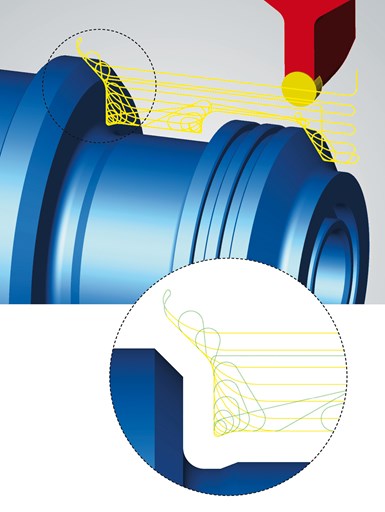

Reducing the depth of cut results in a shallower insert approach angle, making it necessary to increase feed rates to maintain the chip thickness appropriate for the insert and workpiece material. (Photo credits: Open Mind)

The programming algorithms of Hypermill software can enable successful trochoidal turning. Reducing the depth of cut results in a shallower insert approach angle, making it necessary to increase feed rates to maintain the chip thickness appropriate for the insert and workpiece material. Insert edge geometries also require a certain chip load to break chips and maximize efficiency. Round inserts, reduced depths of cut and software strategies that produce soft part entry and exit also improve tool life in difficult-to-machine, abrasive materials with high yield strengths. The software varies feed rate and depth of cut (DOC) to reduce heat generated in the cutting process.

Increased feed rates do put greater stress on machine tool components. Feed rate is directly proportional to metal removal rate, and higher material removal rates place larger demands on the machine tool spindle. However, round, positive-style inserts generally are softer cutting, so in most cases trochoidal turning is suitable for lower power machines. Regarding insert geometry and style, tool manufacturer Ceratizit typically recommends its RCMT and RCGT inserts for trochoidal turning and GX24 inserts for trochoidal grooving, using 4- to 6-mm nose-radii and M3 chipbreakers.

Quantifiable Results

Trochoidal turning is especially beneficial in high-volume production operations such as the manufacturing of traditional automotive components, including axles and shafts.

Round inserts, reduced depths of cut and software strategies that produce soft part entry and exit also improve tool life in difficult-to-machine, abrasive materials with high yield strengths. (Photo credit: Open Mind)

For example, a shop turning D2-equivalent Cr12MoV steel at a 150 mm/min cutting speed, 0.4 mm/rev feed rate and 3.0 mm DOC generated a chip thickness of 0.398 mm and chip volume (material removal rate) of 234 cm3/min. Trochoidal turning is said to enable cutting speed of 350 m/min and feed rate of 2.2 mm/rev while a decrease of DOC to 0.45 mm. Resulting chip thickness in this case would be 0.31 mm while material removal rate would be more than doubled to 592 cm3/min.

Industry Acceptance

Acceptance of trochoidal turning methods is growing as shops realize this approach can offer productivity benefits similar to those of trochoidal milling. Partnerships between tool manufacturers and CAM software companies such as Ceratizit and Open Mind, respectively, will likely result in increased popularity of this alternative turning approach.

Related Content

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)