Optimizing CNC Legacy Parts with CAM

One day’s work resulted in productivity improvements that allow the equipment to pay for itself, while leaving spare capacity for additional production work.

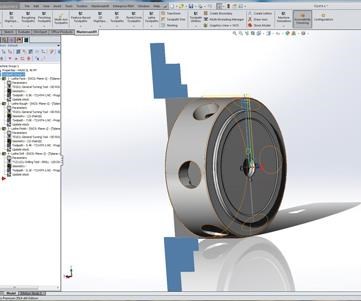

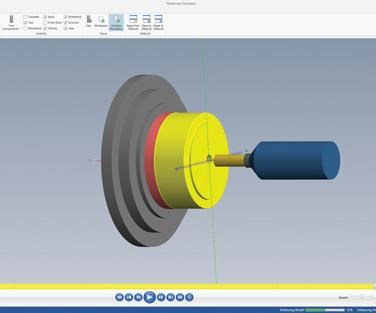

Mark Ellis recently set aside a day to make progress on one of his latest projects—writing CAM programs that would allow a group of 17 parts, manufactured in two setups on an older CNC lathe and mill, to be produced in a single setup on a multitasking CNC lathe with live tooling. During that day, the manufacturing engineer at Mahr Federal Inc. (Providence, Rhode Island) was able to open solid model files for 11 of these parts in his Mastercam software (CNC Software Inc.) to generate optimized CNC programs and prove out several of them on new equipment over the course of several weeks. One day’s work resulted in productivity improvements that allows the equipment to pay for itself, while leaving spare capacity for additional production work.

Mr. Ellis’ work reflects the nature of the current state of Mahr Federal, a precision measurement products manufacturer. The company is in the midst of moving parts previously manufactured on conversationally programmed mills and lathes to the latest CNC equipment with advanced features such as five-axis high-speed machining, mill-turn lathes, multitasking machining centers, a horizontal machining center with pallet-based tombstone fixtures that can be used for lights-out manufacturing, and so on. Over the past five years, the company has invested millions of dollars in these advanced systems that improve capacity and productivity, and maintain strict control of tolerances.

Initially, to get the new multi-axis machining capabilities up and running expeditiously at the company, the conversationally generated code for the existing programs was stitched together manually to create multi-axis programs that could be used on advanced machining centers.

However, now that a sufficient amount of manufacturing started taking place on these systems to keep production moving and to justify their cost, the company is looking to create more optimized cutting programs using Mastercam. Mahr Federal has three seats of Mastercam for SolidWorks with multi-axis mill and lathe capabilities. Mr. Ellis and another engineer have taken training provided by Macdac Engineering, their local Mastercam reseller, and they are using the software to systematically transition a range of new and legacy parts to the newer manufacturing systems and to optimize many of the parts that have already made the transition.

“In my opinion, the savings I have been able to squeeze out of these parts using the software has been incredible,” Mr. Ellis says. “All of our parts are solid models, so I can open the CAD file in Mastercam for SolidWorks and begin plugging away at the CNC program without doing any conversions.”

The software has many tools that can be used to optimize cycles, according to Mr. Ellis. “The fact that Mastercam has a tool library with a catalog of vendor inserts is really helpful. The program automatically selects the vendor-recommended feeds and speeds based on the insert I select, and the material I am cutting. I don’t have to do any hand calculations or adjustments, and it is nice and streamlined.” Mr. Ellis says that fact alone can save him an hour or more per part program, depending on the part’s complexity.

As for the legacy parts, he says he has not found one yet that he hasn’t been able to save time on, and time is worth money.

Mr. Ellis cited a specific part from the family that he reprogrammed for a mill-turn operation as an example of the savings achievable. The part, which was previously manufactured in two operations on a lathe, used to take two minutes, 42 seconds to cut—not including setup time between the two operations. On the new system, the cutting time was reduced to 42 seconds for a complete part. Mahr Federal makes approximately 3,300 of this one part every year, and those cycle time reductions accounted for about $7,000 in annual savings for this one part alone.

“For just those 17 parts, we are looking at around $24,000 in annual savings, which allows us to stay competitive in the market,” Mr. Ellis says. “The machine upgrades cost about $105,000, so those cycle time reductions will pay for the machine in less than five years.”

Mastercam improved Mr. Ellis and Mahr Federal’s time and workload. Using Mastercam to program mill and lathe cycles for four of these parts took only one day. Mr. Ellis says it would have taken twice that time to manually write far less efficient programs.

Also, during his time programming with Mastercam, he brought the equipment’s workload up from about 60 percent yearly capacity to 82 percent full capacity. So there is still more room for additional production to be run on this one machine.

Related Content

Integrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

Read MoreVerisurf Probing Suite Provides Flexibility in Quality Inspection

Verisurf’s Machine Tool Probing (MTP) suite is an in-process automated inspection solution for CNC machine tools, offering inspection and reporting capabilities.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreRead Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)