Overall Organizational Effectiveness: How Do You Know?

Sales are great! I think. How do you know unless you can compare to your peers? PMPA’s Business Trends Report can help.

I attended IMTS 2022 in Chicago, Illinois, and one of the most vivid sights for me was an entire hall filled with hundreds of vendors supplying various Overall Equipment Effectiveness (OEE) software, dashboards and machine monitoring/reporting technologies. An entire hall! OEE shows you the performance of your operations, compared to their available potential — but nothing about your position and performance relative to the market, and your competitors.

The PMPA provides a Monthly Business Trends Report for its members. Image Credit: PMPA

Where can you go to get credible and authoritative information to use to evaluate your organization’s performance in the market, your industry and the broad economy? Today’s world is characterized by Volatility (such as the price of energy), Uncertainty (such as the availability of critical raw materials), Complexity (such as the latest revisions on tax and depreciation rules) and Ambiguity (such as is it still a pandemic? Endemic? Is it over?). In such a VUCA world, you need a trustworthy resource that gives you a credible means to know where you stand in regard to the broad issues in which you operate. You need information that is curated to be appropriate for your niche, which provides actionable understanding of performance relative to your peers. Where do you go to get trusted data to benchmark your organization’s performance?

PMPA – Effective Associating Means Sharing Actionable Data for the Good of the Industry

PMPA is a 501(c)6 trade association, referred to as a “business league” under the IRS code. “A business league’s activities must be devoted to improving business conditions of one or more lines of business … they direct their efforts at promoting the common economic interests of all commercial enterprises in a trade or community.” bit.ly/PMPA-PM1122

At PMPA, our mission statement challenges us to progressively lead members to sustainable success with reliable and relevant information, resources, advocacy and networking opportunities.

Among our many informational deliverables — which include economic updates, annual wage surveys and reports — is our Monthly Business Trends Report. Our Business Trends Report consolidates the (confidentially submitted) sales and hours of first shift scheduled data from about 35% of our manufacturing membership. In addition, we track four sentiment indicators for the next three months for outlook for sales, lead times, employment and profitability. Because our reporting shops are all precision turned products shops, NAICS 332721, the inferences that our reporting gives us is focused and accurate — and a suitable standard for benchmarking your shop’s experience.

Our shops’ performance in the short term does not correlate well with broader indicators such as Industrial Production, Manufacturing Output, Durable Goods or GDP. In fact, over the past year, our shops have often outperformed most of these indicators. However, because of the shared processes, customers, markets, suppliers, scale, scope and capabilities common to all of our precision machining shops, the aggregation and sharing of our collective data leads us to discover “the wisdom of the crowd.” Our monthly cadence helps you to compare your shop’s sales and scheduled overtime performance to that of your “comparable peers.” Similarly, you can compare the outlook that you have for the next three months with that of your peers/competitors. What are you missing? What are they seeing? Is there a gap?

How Do You Know?

Here are three potential situations in any given month for your shop’s sales performance:

- Your sales came in double digit percent higher last month. Was it due to good sales by your organization? Was it because you needlessly discounted? Was it due to the economy?

- Your sales dropped double digit sales percent last month compared to prior month. Much lower than the economy.

- Your sales came in up double-digit percent higher than last month. What can we expect for next month?

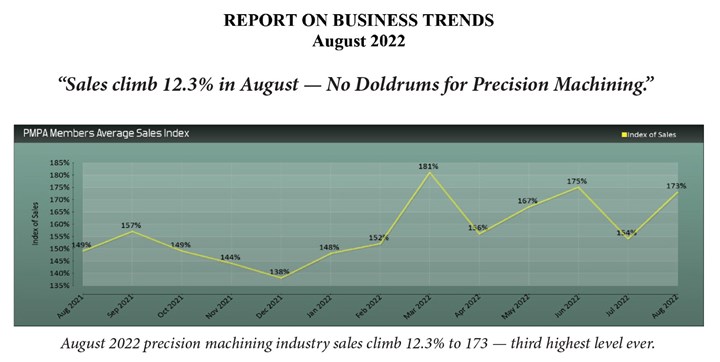

This past year, as of August, all eight months’ Business Trends sales came in at higher levels than the 2021 calendar year average. Despite two major declines in March at 181 to April at 156 (a 13.8% drop) and June at 175 to July to 154 (a 12% drop), our shops had confidence they were outperforming. Our sentiment indicators showed that outlooks for lead times were holding steady, and we could all compare outlook for profitability and employment prospects going forward. Our discussion in each monthly report showed how our shops compared to the Federal Reserve’s Industrial Production and Manufacturing Output Indicators.

Here is what we said in August: “According to the Federal Reserve, Industrial Production decreased 0.2% in August. Manufacturing output edged up 0.1% after increasing 0.6% in July.” Here is how the PMPA participating shops performed for that same period: “The PMPA Business Trends Sales Index increased from 154 in July to 173 in August, a gain of 19 points (12.3%). This is our index’s third highest value ever … PMPA’s Business Trends August Sales increase substantially outperformed the sales of the broader industrial production sector’s performance.”

How do PMPA shops know if their organizational performance compares to that of their peers, their industry or sector?

By effective associating. By sharing, in complete confidentiality, a few items of relevant data and sentiment. By aggregating data from trusted and known peers, PMPA is able to provide inferences that “promote the common economic interests of all commercial enterprises in a trade.” Where do you go to get trusted information? We invite you to join PMPA and become part of a trusted community of peers and get your own company’s personalized Business Trends snapshot reported to you monthly. Know where you stand compared to the broad economy, the industrial and manufacturing sector, and your peers. Get a forecast of sentiment looking ahead three months. And, when you join, we will share with you how our early in the year data reliably forecasts the end-of-the-year sales average. How much more comfortable would your decision-making be based on trusted data?

Read More Articles from PMPA:

- You Didn’t Read My Email?

- Craftsman Cribsheet No. 112: PMPA Speaking of Precision Podcasts — Business/Continuous Improvement/Workforce

About the Author

Miles Free III

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email – mfree@pmpa.org; website – pmpa.org

Related Content

A No/Low-Cost Solution to Employee Retention

Studies show a little employee recognition goes a long way. Here are the 5Ws to consider for success.

Read MoreOnshoring Weather Report: Strong Tailwinds!

Onshoring, reshoring, nearshoring: these terms are showing up with increasing frequency in the news and online. But is there evidence that these are real?

Read MoreCraftsman Cribsheet No. 129: How to Beat the Heat

Shops tend to heat up in the summer. Here are some tips for staying cool in the warmer months.

Read MoreCraftsman Cribsheet No. 128: Why Do Machinists Say Tenths Instead of Ten Thousandths?

In machinist parlance, a tenth is a tenth of a thousandth, not a tenth of an inch.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More