Ready or not, “squeaky” clean parts are becoming more critical in the precision machining industry. Especially if a company is a supplier to an automotive OEM, tough cleanliness standards are demanded. Ensuring the parts your company is producing are clean, and not only to the naked eye, but to stringent regulations as well, is likely to be reality soon, if not already.

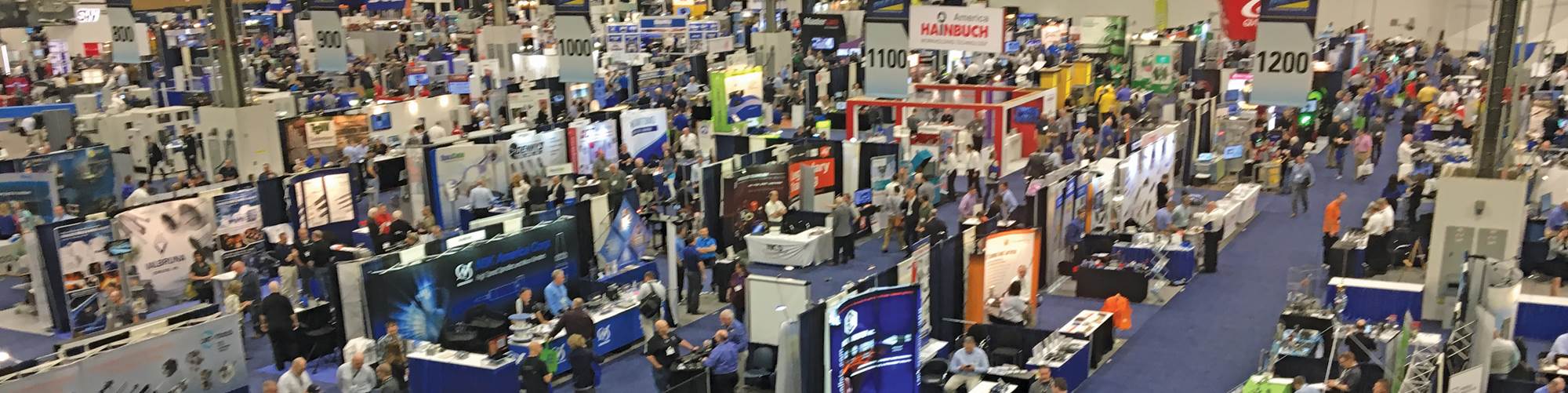

Many of the companies that create products to help machine shops comply with these cleanliness standards will be exhibiting and ready to answer questions and help solve cleaning problems at this year’s edition of the Precision Machining Technology Show (PMTS 2019), April 2-4, at the Huntington Convention Center in Cleveland, Ohio. The show is presented by the Precision Machined Products Association (PMPA) and is co-hosted by the Production Machining, Products Finishing and Modern Machine Shop brands.

The parts cleaning exhibitors at this year’s edition of PMTS provide products to the industry such as ultrasonic cleaning systems, chemical solvents and cleaning fluids, drying systems, rust preventatives, cleanliness analysis microscopes, oil skimmers, and much more. Many of these exhibitors are also participating in the Parts Cleaning Conference, which will be held in conjunction with PMTS, offering attendees a deeper dive into the technical aspects of parts cleaning. Presentations include topics such as “Evaluation and Control of Cleaning Processes,” “Maximizing the Performance of your Aqueous Cleaning and Rust Protection Programs,” and “How to Justify a Parts Cleaning Machine” (see full agenda here). Breakout sessions are also offered this year that will cover critical cleaning, trends and technology, and basics and best practices in parts cleaning.

To get a feel for the current hot topics in parts cleaning prior to the show, we asked several of the exhibitors what attendees should expect the show “buzz” to be as well as their thoughts and insights about the show and conference.

Cleaner Parts

Most of the industry professionals we spoke with said their customers are asking about how to achieve cleaner parts during this time of transition to increasingly stringent regulations.

Ecoclean account manager Rob Campion says his customers are especially interested in closed loop or airless, air-tight systems in order to comply with new regulations that are either already in place or soon to be implemented. The company’s product line manager, Sandro Siminovich, also says customers are asking about tighter cleanliness specifications. “We are ready to address such inquiries with new products and technologies, such as remote diagnosis built into the machines, new CNC high pressure deburring and solvent/modified alcohol machines that are 100 percent enclosed and count with high precision ultrasonic and filtration systems to resolve difficult cleaning tasks.”

Suppliers to OEMs especially may be seeing a demand to tighter cleanliness specifications on a per-component basis as well as for assemblies, says Peter Feamster, product management director at Jomesa North America. “The demand for particle analysis has been increasing steadily over the past five years,” he says. “More recently, we have often been asked to analyze contamination particles not only for size and count, but for elemental composition as well.” Jomesa recently released the PSE (precision scan for elements) system, which allows for optical analysis data to be shared with SEM/EDS (scanning electron microscopy/energy-dispersive X-ray spectroscopy) analysis. “This is a great advantage for large-volume production due to the slow processing times normally associated with SEM/EDS analysis,” he says. “With the PSE, optical and SEM/EDS results can be stored and reported together in one comprehensive software.”

Safe Cleaning Chemistries

Safe cleaning chemistries are important to companies who need to clean their machined parts, according to David Ferguson, senior technical manager for MicroCare Corp. “Customers want to be sure that the precision cleaning fluids being used are safe, not only for workers, but also for the environment,” he says. This is due in part to global government restrictions limiting the use of these substances.

“Many companies want to move away from cleaning fluids containing propyl bromide (nPB), trichloroethylene (TCE), perchloroethylene (perc) and methylene chloride to better and safer alternatives,” Mr. Ferguson says. MicroCare helps its customers replace old chemistries like these with newer and safer alternatives. According to Mr. Ferguson, “By collecting all the necessary information from the customer including current cleaning chemistries, process requirements and equipment information, we can determine what cleaning fluid will best perform as a replacement. We even clean customers’ parts in our Critical Cleaning Lab to ensure our recommendations work well and are the best fit for the company’s specific requirements.”

To demonstrate the use of modern high-performance precision cleaning fluids, MicroCare will have a working vapor degreaser in its booth at PMTS 2019 and encourage attendees to bring their parts to the booth for evaluation and testing. “Customers are usually surprised by the cleaning results and the fact that they can get a lower cost per part,” Mr. Ferguson says.

Other Burning Issues

Besides cleaner parts and safe cleaning chemistries, parts cleaning customers are also inquiring about vacuum drying, steam cleaning and water-based rust preventative with long-term protection for overseas shipping, according to Jason Fulp, marketing coordinator at JRI/Jenfab.

Remote connectivity, U.S.-built and -supplied components, optics with autonomous driving and surgical/medical cleaning solutions are other popular inquiries from Ecoclean’s customers as of late.

Keeping coolant clean is also critical when producing quality parts. Guy Flynn at Oil Skimmers Inc., says it’s important for him to teach his customers to remove the tramp oil from coolants to extend the life of the coolant, keeping the spray lines and nozzles lasting longer and functioning properly and keeping anaerobic bacteria from forming. “If you don’t remove the tramp oil, it can cause degradation of the machine tools and clogging and degradation of spray lines and nozzles, potentially resulting in a lesser quality product.” Oil Skimmers Inc. will be exhibiting for the first time at PMTS 2019.

The PMTS Advantage

PMTS exhibitors enjoy the show because of the opportunities it offers them and the attendees they serve. They say exhibiting includes the opportunity to introduce new products, meet new customers, generate leads, learn about new opportunities within the industry, network with companies and attendees, and to benchmark with competitors.

Although PMTS 2019 will be Jomesa’s first time to exhibit at the show, Mr. Feamster says he’s aware that the show’s parts cleaning focus and relevance to the attendees has increased significantly through the years. “We look forward to meeting new customers in the precision machining industry,” he says.

Since Ecoclean has exhibited eight times at PMTS so far, company employees who have been at PMTS are able to report that they have seen the show evolve. “We have seen an increase in the number of exhibitors, and the technical conferences are getting more attention than in the past,” Mr. Siminovich says.

MicroCare’s Mr. Ferguson also recognizes that the number of exhibitors has grown, as his company is also a veteran exhibitor. “The content and variety of presentations has also grown,” he says. “Attendees are now looking for better and safer ways to clean critical parts, and so we have seen an increasing interest in modern precision cleaning solutions.”

JRI/Jenfab has exhibited at least five or six times at PMTS. “The show changes with the industry and is one of the only trade shows specifically targeted to our industry,” Mr. Fulp says.

Although finding the best way to achieve critical clean parts may be overwhelming, PMTS exhibitors such as the companies we featured in this article are ready and willing to help, and in fact, are in the business to serve their industry. Take advantage of the expertise these companies have to offer and visit their booths at the show. Also register for the Parts Cleaning Conference to make the most out of your visit.

For more about the Parts Cleaning Conference, and to register, visit partscleaningevent.com.

Find a full agenda for the Parts Cleaning Conference here.

Related Content

Syncrex Swiss-Styles for Fast Tool Setup, Easy Programming

PMTS 2023: The Mazak Syncrex series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

Read MorePMTS 2023: Discovering Precision Machining Technology Under One Roof

Like Production Machining, trade shows such as PMTS enable you to discover new shopfloor equipment, technology and ideas that can help boost your shop’s efficiency and profitability.

Read MoreThe People Part of PMTS

The Precision Machining Technology Show is a great example of discovering ways shopfloor employees can become more efficient, thereby helping shops become more profitable.

Read MoreStar CNC’s Swiss-Type Lathe With Double B-Axis Programmable Units

PMTS 2023: The SD-26 Swiss-type automatic lathe has features designed to offer enhanced workability and operability for the operator from both a hardware and software perspective.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More