Every month, we’re putting together a Technology Showcase to highlight new product information that PM has received from supplier companies. For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining’s free monthly print magazine.

Read PM’s Precision Machining Technology Review March 2024.

Sumitomo Turning Grade Provides Long Tool Life in Cast Iron Applications

Source: Sumitomo Electric Carbide Inc.

Sumitomo has developed its AC4125K turning grade to lower overall tool usage and tool-change frequency while providing stable, long tool life in cast iron applications in the automotive industry, among others. Gray cast iron is used for parts like engine blocks and brake discs where sliding is required, while ductile cast iron is used for parts such as differential cases and carrier cases where strength is required. Gray cast iron is an alloy primarily composed of carbon and silicon. Gray cast iron appears gray on the fracture surface because carbon is more present in the form of graphite than in the form of cementite. Ductile cast iron contains somewhat more carbon and silicon than gray iron, with the graphite becoming spherical due to the addition of magnesium and/or cerium.

Horn Toolholder Features Multiple Coolant Connections

Horn USA Inc. has combined the features of various toolholders into its 224 grooving system. The new toolholder features two coolant connections, which are made either via a transfer on the contact surface or via a threaded connector on the side. The internal coolant supply is fed directly to the insert via the clamping finger or directly to the flank face via a hole.

Horn offers the toolholder in a compact design as a square shank of dimensions 0.63" × 0.63" (16 mm × 16 mm), 0.787" × 0.787" (20 mm × 20 mm) or 0.984" × 0.984" (25 mm × 25 mm). All toolholder sizes are available from stock for widths of cut of 0.079" (2.0 mm), 0.098" (2.5 mm), 0.118" (3.0 mm), 0.157" (4.0 mm), 0.197" (5.0 mm) and 0.236" (6.0 mm). The tool shanks are made of high-strength steel, which provides high precision of the insert seat and a long service life of the system.

Tungaloy CBN Inserts Boost Productivity in Hard Part Turning

Tungaloy has upgraded its MiniForceTurn by introducing 30 new DXGQ/U0703 inserts with brazed cubic boron nitride (CBN) tips and an HP chipbreaker. This upgrade is said to boost productivity in hard part turning applications. The CBN inserts will now be sold in newly designed boxes containing five inserts each.

MiniForceTurn turning tool series offers double-sided turning inserts with positive-rake cutting edges on both sides. These inserts enable free cutting action like that of positive inserts with an added advantage of double cutting edges.

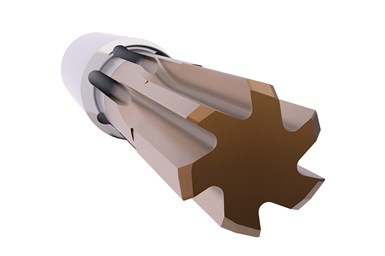

Emuge-Franken Threading Tools Mill Challenging Materials

Source: Emuge-Franken USA

Emuge-Franken USA has expanded its line of thread mills for challenging threading applications and materials such as nickel alloys, titanium, high-tensile-strength steels, hardened high-alloy steels, cast iron, cast aluminum and more.

The Threads-All family of thread mills that are well suited for demanding materials and industries such as aerospace, where nickel alloys, titanium and stainless steel are the norm. The family now includes the Max line of premium sub-micron grain solid carbide thread mills that are designed for maximum performance in high tensile strength and hardened materials from 44-66 HRC. Emuge has also added the new Headed line, featuring circular thread milling bars and bodies with exchangeable face inserts. The line is designed to provide a modular solution for milling larger thread dimensions in stainless steel, titanium, nickel alloys, cast iron and hardened high alloy steels >25 HRC, as well as mold and tool steels.

In addition to the Threads-All tool lineup, Emuge-Franken has also expanded four other solid carbide thread mill tool families.

Seco Tools' Reamers Optimize Chip Evacuation

Seco Tools’ Nanojet solid-carbide reamers enhance chip control with a through-coolant outlet for optimal chip evacuation. According to Seco, this design eliminates costly scrapped parts, jamming and edge damage to increase safety, part quality and tool life.

On blind and through bores, Seco’s Nanojet reamers stop chip jamming and enhance application stability. The specialized design of these new tools delivers a powerful, precise stream of lubrication directly to the cut zone for optimal chip evacuation and tool life. Seco Nanojet solid-carbide reamers maintain cutting speeds as well as part quality, contributing to production stability.

Sandvik Coromant Parting Tool Provides Improved Surface Quality

Sandvik Coromant has upgraded its CoroCut QD Y-axis parting tools to enable improved surface quality, reduced vibration and higher blade stiffness.

CoroCut QD enables for the parting off of much larger diameters than what is currently possible with conventional methods, according to the company. Additionally, shifting the resultant load to the strongest section of the blade creates six times higher blade stiffness, enabling increased feed and longer overhangs without losing stability.

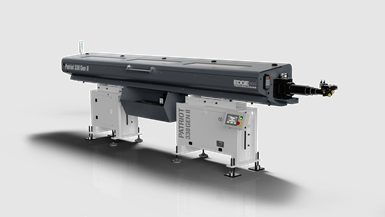

Edge Technologies Bar Feeder Maximizes RPM Potential

Source: Edge Technologies

Edge Technologies’ second-generation Patriot 338 and 551 include enhanced features, new sheet metal and a new color scheme.

Faster changeovers, ease of use and safety were the driving forces incorporated from customer feedback and thousands of installations, the company says. Edge Technologies has equipped the latest Patriot bar feeder with quick-change guide channel sets, a larger viewing window and an internal LED light bar around the gripper area — features that ease setup and production monitoring. The main bushing device and second movable anti-vibration device (MAVD) are improved to stabilize bar stock between guide channel and lathe spindle, maximizing rpm potential.

Starrett Video System Provides Secure Measurement Data

Source: The L.S. Starrett Co.

The L.S. Starrett Co. has introduced the latest video system, the KMR-MX 200 Manual Video System. The new system offers a specialized platform that is said to fill the gap for companies that want the speed and accuracy of a video-based platform, but do not need Windows-based software or a PC. Well suited for a range of industries such as medical, aerospace, defense and others that require traceable and secure measurement data, operators can take a wide range of measurements with the system.

General Inspection Gaging System Provides Rapid Part Measurement

Source: General Inspection

General Inspection’s VisionLab gaging system enables first piece inspection, statistical process control (SPC) sampling, final audits or 100% inspection using pick-and-place automation. VisionLab measures all profile characteristics and is the only 3D gaging system that provides complete part measurements in less than seven seconds, according to the company.

The VisionLab system can measure all profile features, including pertinent geometric dimensioning and tolerancing (GD&T) characteristics as well as all thread features using its optics and software algorithms. An integrated thread database provides point-and-click programming. An optional end-view feature measures and detects defects on both ends of parts measuring features such as recesses, IDs, ODs, through holes and counterbores.