Every month, we’re putting together a Technology Showcase to highlight new product information that PM has received from supplier companies. For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining’s free monthly print magazine.

Read PM’s Precision Machining Technology Review January 2024.

Index Corporation Lathes Feature 18 Toolholders

Source: Index Corporation

Index Corporation’s CNC universal lathes, which includes models Index B400/B500 and Traub TNA400/TNA500, have been upgraded to feature 18 tool locations.

The four Index universal lathes share many common features: the Index B400/B500 and Traub TNA400/TNA500 all use the same machine bed, cover and inner cover, and have identical slide systems. Yet, there are a few differences between them, including the control technology they use. While the Index B400 and B500 feature Siemens’ Sinumerik 840D sl, the Traub TNA400 and TNA500 are equipped with the Traub TX8i-s V8 controller based on Mitsubishi controls.

Edge Technologies Bar Feeder Automates Short Production Runs

Source: Edge Technologies

Edge Technologies has released an updated version of its Rebel 80 short loading machine. According to the company, the Rebel 80 Servo v3’s enhanced features and user-friendly design make it a specialized solution for automating short production runs at an economical price.

The Rebel 80 Servo v3 features an improved conversational control with a new touchscreen human-machine interface (HMI) and 300-program storage. The system is well suited for advanced interfacing and more involved applications like shaft loading, while still prioritizing ease to use for short-run applications that require quick changeovers.

Edge Technologies has added rollers to the V tray, two polycarbonate windows to observe bar loading and a folding axial shift (X axis) that streamlines the footprint and allows for maintenance access and spindle-liner changeover.

Kyzen Solvents Provide Ease of Cleaning for Medical Parts

Kyzen Corp.’s Metalnox solvent products are designed to improve reliability and increase the ease of cleaning medical devices in vacuum and vapor degreasing processes. They also serve as environmentally friendly drop-in replacements for hydrofluoroethers (HFE) solvents and substances containing per- and polyfluoroalkyl substances (PFAS).

SMW Autoblok Vise System Provides Omnidirectional Clamping

Source: SMW Autoblok Corp.

SMW Autoblok’s Plus5 V5 Zero Point Vise system locks and unlocks pins with only 180o rotation. Omnidirectional clamping is said to ensure uniformity while performing precision, all-directional, clamping. This zero-point vise interfaces with all industry-standard products using 52 mm or 96 mm pin spacing, enabling it to readily become part of existing workholding systems.

The V5 Vise system provides self-centering operation for five-axis machines. The device has fully protected and sealed lead screws and incorporates SinterGrip inserts for multivise integrations and eliminating dove tailing or crimping operations. The vise can locate, support and secure workpieces in a variety of manufacturing operations, including machining, welding and assembly.

Walter Indexable Drill Inserts Provide High Wear Resistance

Walter’s low-adhesion WNN15 grade is now included in the company’s indexable insert drills. The drills that accept indexable inserts made of grade WNN15 include D4120, D3120, and B3212.DF. to B3214.DF in insert versions P4840, P2840 and LCGX.

The grade is primarily designed for drilling wrought or cast aluminum alloys (ISO N workpiece group). Applications for these alloys are mainly found in the aerospace and automotive industries, as well as in general mechanical engineering.

Tungaloy Modular Turning System Provides High Repeatability

Tungaloy has updated its ModuMiniTurn modular turning-tool system for Swiss machines by adding 30 new, round-shank toolholders that are suitable for machining the back side of the parts in the subspindle.

The ModuMiniTurn modular turning tool system incorporates a specialized coupling mechanism between the modular head and tool shank, which reportedly achieves repeatability accuracy within the 5-μm range and minimizes downtime during tooling changeovers. The system offers standard modular heads for a range of applications, including forward turning, back turning, grooving, thread turning, parting and productive Y-axis turning.

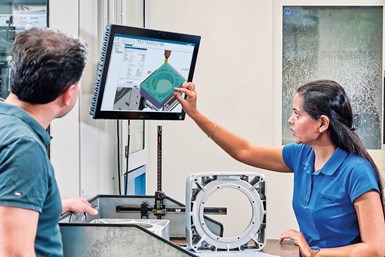

Siemens CAM Software Update Provides Streamlined Workflows

Siemens Digital Industries Software has announced the latest version of NX for manufacturing, which includes new features and product updates to NX CAM, NX CAM On-Machine Probing and more.

The new quick roughing operation in NX CAM software offers a swift and easy-to-program offset roughing process with a user-friendly interface and streamlines the creation of roughing operations with minimal input. The new face milling operation provides modern programming techniques to interactively adjust toolpath parameters. The operation now features zig-zag patterns to make it easier for users to program face milling toolpaths. Additionally, the latest wall finish barrel swarf operation helps users reduce machining time and improve surface finish using advanced settings to generate optimized toolpaths easily. Users can now use taper barrels for parts with straight walls and tangent barrels for parts with curved walls.

.png;maxWidth=300;quality=90)