Lazy summer days are not a time for anyone to sit idle in the precision machining industry. Stay up to date on the latest new and/or improved products and learn how they might improve your manufacturing efficiencies.

We’re putting together Technology Showcases to highlight some of the product information that PM receives from supplier companies. For June, we’re focusing on machining centers, including a gun barrel processing cell that incorporates drilling, reaming and rifling; a three-spindle machine that offers greater size, power; a VMC that combines strength with speed for optimum productivity; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s May Technology Review.

Click on each link below to read the full product post:

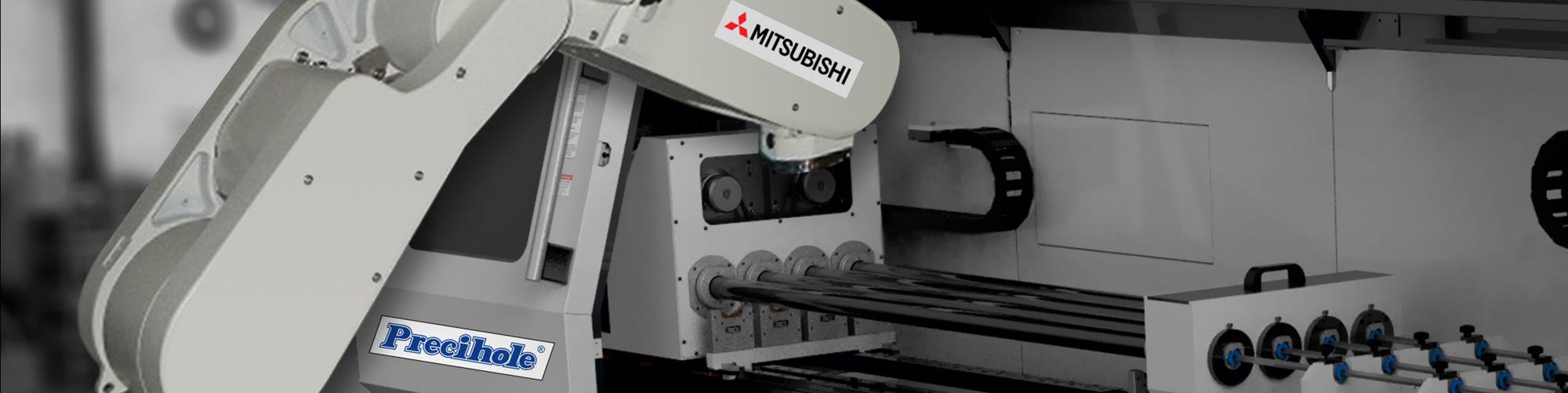

Absolute Machine Tools’ Precihole machines can be combined into processing cells that enable efficient drilling, reaming and rifling.

Absolute Machine Tools’ Precihole machines can be combined into processing cells that enable efficient drilling, reaming and rifling as many as 20,000 small-caliber firearm barrels a month. A cell is typically composed of three machines. First, Precihole’s four-spindle gun drilling machine permits deep drilling of four barrels simultaneously. An open machine configuration facilitates robot access, minimizing operator involvement and supporting 24/7 operation. Depending on individual model configuration, the machine can drill IDs from 0.04" to 1.57" and barrel stock from 0.4" to 4.0" OD.

Porta Solutions 3-spindle PortaCenter 500

Porta Solutions’ 3-spindle PortaCenter 500 is has the same machining concept as the 250 model, but everything about it is much larger. This flexible CNC machine has a 500-mm working cube and offers great power for removal up to 33 kW at the spindle. It also has an optional turning work module, with 24 or 40 tool positions.

Expand Machinery’s Genmill 4024 VMC

Expand Machinery’s Genmill - 4024 VMC combines strength with speed for high productivity, and features travels of 40.5" in X, 23.6" in Y and 25.6" in the Z-axis. The rigidity of the Meehanite processed cast iron frame provides a high-strength cutting platform with superior vibration damping and efficient metal removal rates. The 12,000-rpm, 25-hp direct-drive inline #40 taper spindle features rigid tapping and includes a thermostatically controlled spindle oil cooler.

Romi hybrid manufacturing machining center

Romi’s line of hybrid manufacturing machining centers combines traditional machining operations with 3D metal additive manufacturing (AM). Its Generation D Series vertical machining centers (VMCs) are the basis for this line of hybrids and include the D 800, the D 1000 and the D 1250. The company says the three models have a robust and heavy casting, roller guides on all axes, a Big Plus direct-drive spindle and a maximum machining volume of 31 × 24 × 25", 40 × 24 × 25" and 50 × 24 × 25", respectively. Also available as a hybrid is the Romi DCM 620-5X 5-axis VMC.

Eight independent axes make the AF160 a versatile gear hobbing machine.

The Affolter AF160 is an 8-axis CNC gear hobbing machine designed for high-precision manufacturers that need versatility and maximum efficiency. With eight axes, a digital CNC control and a variety of automation solutions, it is well suited for manufacturers in industries such as automotive, aerospace, aircraft, gearbox, medical and robotics. It can handle a range of applications to produce different kind of gears and worm screws with a module of up to 2 mm.

The Zeltwanger X-Cell is a smart laser cell for various machining processes.

The Zeltwanger X-Cell is a smart laser cell for various machining and manufacturing processes. Standardized, modular and usually robot-based – the machining, testing and handling cell X-Cell is a smart laser which integrates a variety of processes into the production workflow. The core processes include laser cutting, laser welding, laser marking, leak testing and machine tool loading.

.jpg;maxWidth=300;quality=90)