Every month, we’re putting together a Technology Showcase to highlight new product information that PM has received from supplier companies. For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s Precision Machining Technology Review October 2023.

Horn Tool Configurator Shortens Lead Times

Photo Credit: Horn USA Inc.

Horn’s HTC tool configurator system is designed to supply gear milling cutters in a short lead time. The HTC system offers the possibility of automatically generating a tool drawing for all gear profiles up to module 3, shortening the design phase. The system reportedly enables quotations to be generated within one working day, with technical drawings available the next working day. With the Greenline process, Horn offers delivery within five working days. The number of pieces is limited to a batch size of 50 and approval of the drawing by the customer is a prerequisite.

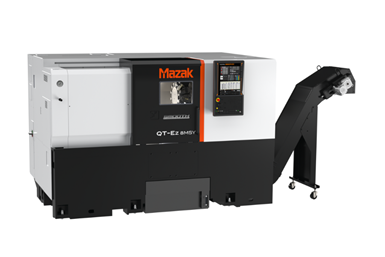

Mazak Horizontal Turning Center Enables Versatile Machining

Photo Credit: Mazak North America

Mazak’s QT-Ez 8MSY horizontal turning machine features milling and Y-axis capabilities paired with a second turning spindle. The versatile, automation-ready machine also integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

The QT-Ez 8MSY features a 20" bed sports an 8" chuck as standard equipment, with a 6" chuck as optional. Available machine turrets include two-axis drum style with a bolt-on or BMT55 turret for rotary tool applications.

Kyocera Precision Tools' Coated Carbide Optimizes Turning

Photo Credit: Kyocera SGS Precision Tools Inc.

Kyocera Precision Tools has announced its new CA115P/CA125P next-gen chemical vapor deposition (CVD) coated carbide for steel machining. This new offering combines an innovative coating, carbide substrate and chipbreakers to deliver exceptional performance, wear and fracture resistance.

Kyocera has designed the CA115P/CA125 series to provide extended tool life and superior performance in a variety of machining scenarios. The CA115P is ideal for continuous to light-interrupted machining, offering highly efficient and precise results. Conversely, the CA125P is optimized for continuous to heavy interrupted machining, making it a versatile general-purpose tool for steel machining.

Sandvik Coromant Drill Provides High Hole Integrity

Photo Credit: Sandvik Coromant

Sandvik Coromant has introduced a new solid carbide drill optimized for drilling in nickel-based, heat-resistant super alloy (HRSA) materials, with a standard drilling depth capability of up to 8 × D.

According to Sandvik Coromant, the new CoroDrill 860 offers a consistent and predictable tool life with high hole integrity, which is important for applications with high demands and processes in place to safeguard quality, such as the aerospace industry.

There are several features that contribute to the high performance for HRSA materials. First is the specialized grade — S2BM — which combines a fine-grained cemented carbide substrate, a multilayer physical vapor deposition (PVD) coating and a post-treatment, delivering maximum tool life. Additionally, it features geometry with optimized clearance angles and highly controlled edge preparation, flute shape, corner chamfer and double margin, providing performance and process security.

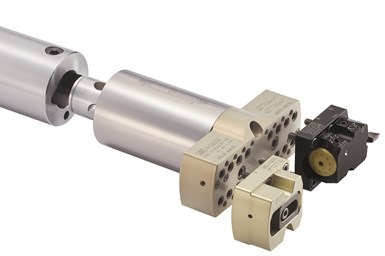

Big Daishowa Enhances Boring Tools With Vibration Damping

Photo Credit: Big Daishowa

Big Daishowa has expanded its lineup of Smart Damper-integrated products to include 318 Large Bore Systems and the CK1, CK2 and CKB3 systems.

The new 318 Smart Damper deep boring system is for fine or rough boring of diameters from 200-320mm (7.87-12.6") and uses the CKB7 connection to adapt to almost any machine. The integration of Smart Damper shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration. This produces higher damping effects to the tool assembly to minimize vibration and achieve better surface finishes and improved metal removal rates. According to Big Daishowa, the 318 Series’ low weight and secure configuration make it well suited to high-speed operations (up to 6,600 SFM).

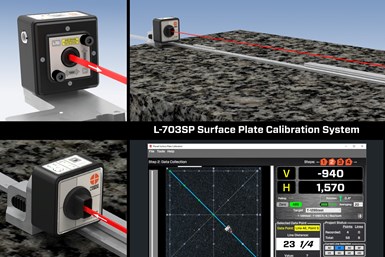

Hamar Laser's Calibration System Shortens Setup Times

Photo Credit: Hamar Laser Instruments Inc.

Hamar Laser Instruments Inc. has released its L-703SP Surface Plate Calibration System. The L-703SP is a compact geometry laser-based calibration system that is highly repeatable, offers high resolution and accuracy, easy setup and training, as well as fast data collection. Hamar says its R&D and field testing have shown that the L-703SP reduces the time for calibrating surface plates by 30-60% versus conventional methods.

The L-703SP is said to be 30-40% faster than electronic levels, as well as more rugged, reliable and repeatable. In addition, the L-703SP is set up directly on surface plates, so each line segment setup is easier than autocollimators and laser interferometers, which require floor mounting and touchy setups. This results in faster plate calibrations and, unlike these devices, does not require re-taking data if the laser beam is broken.