For Swiss-type turning of watch screws, Aeschlimann relies on Horn’s µ-Finish tools and Tornos Swiss Nano CNC sliding headstock machines. (Photo credits: Paul Horn GmbH)

To ensure that the famous “Swiss movement” of a watch runs smoothly, in addition to numerous precision components and gears, the precision mechanical masterpiece must ultimately be held together by screws. Their production requires a great deal of know-how, so it is no wonder that well-known Swiss watch manufacturers rely on micro-precision screws from their own country. One manufacturer of such screws is Aeschlimann AG Décolletages from Lüsslingen in the canton of Solothurn, Switzerland. For micromachining, the specialists led by trained micromechanic Mattia Knecht rely on the µ-Finish system from Paul Horn GmbH. Knecht receives technical advice on tooling issues from Dominik Läng, an engineer at Dihawag, Horn’s sales agent in Switzerland.

From micro watch components to parts for the medical industry to excavator hydraulic components, Aeschlimann AG Décolletages is considered a specialist in the manufacture of precise, rotationally symmetrical workpieces. Founded as a screwmaker’s workshop in 1937, the company has evolved into a manufacturer of complex CNC components and offers its customers’ specialized finishing processes such as honing, cylindrical and centerless grinding, and options for super-finishing. With 165 employees, the company primarily produces turned parts with diameters as large as 120 mm. However, Aeschlimann also demonstrates expertise in milling parts that can be as long as 300 mm. Its customers include companies from the watchmaking, automotive, hydraulics, machinery and electronics industries. In addition, Aeschlimann supplies precision Swiss components to the medical, metrology and bicycle industries.

Production of Delicate Watch Components

Depending on its quality, a Swiss watch movement consists of many individual components including the gear train, winding mechanism, drive, balance and hand movement. In a complicated, high-quality watch, many components are assembled into a movement within a very small space, and screws are used to assemble the individual components.

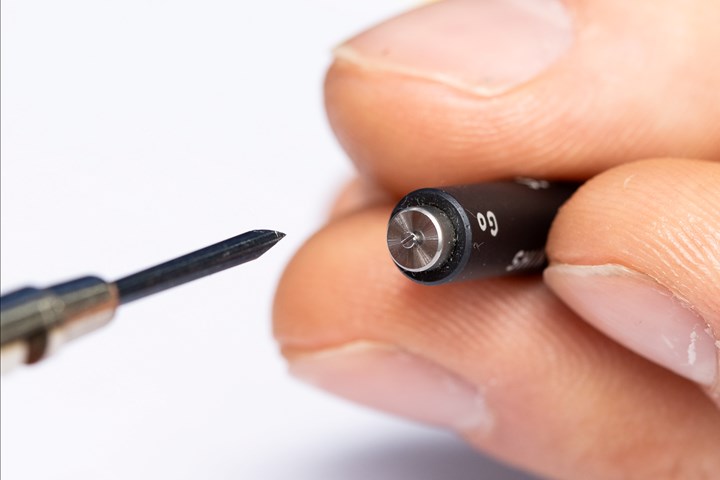

Manipulating a thread ring gage requires considerable dexterity.

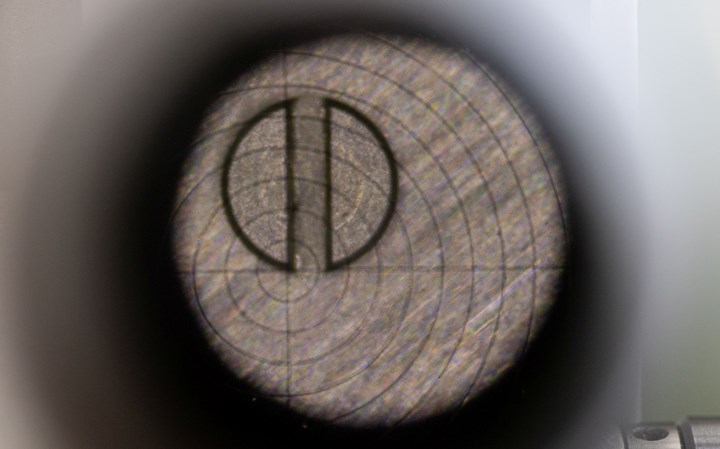

To produce these screws, an average machinist would probably find it very difficult. With the naked eye, the workpieces can hardly be distinguished from a piece of fine swarf. “Handling and measuring the screws is a considerable challenge that requires a lot of practice,” Knecht explains. “The dimensions are not checked with a micrometer, but under a microscope with 50-fold magnification.” The dexterity required to handle the screws is also evident when checking the threads with a thread ring gage. “You need a lot of experience to turn screws with diameters far below one millimeter into a thread gauge by hand,” he notes.

With the naked eye, the workpieces can hardly be distinguished from a piece of fine swarf.

Aeschlimann relies on the Horn µ-Finish tool system and Tornos Swiss Nano machines for sliding-headstock turning of watch screws. Micromachinists are the main target market for this range of tools, which is based on the S274 system. The inserts are precisely ground and each tool undergoes a 100% inspection during production to ensure a high-quality cutting edge. The insert seat of the tool carrier, in conjunction with the central clamping screw and the ground periphery of the indexable insert enables a changeover accuracy within microns. This enables the insert to be rotated in the machine without having to remeasure the center height and other dimensions.

The watch screws are inspected under a microscope using an in-process measuring system.

“Horn offers high-end tools for many applications,” Knecht says. “From watch screws to medical industry components and hydraulic parts, there are solutions. We use Horn tools on a range of our machines.” In addition to numerous standard profiles, inserts with special shapes are also available to meet customer requirements.

Feed Rates in the Micron Range

“The quality of the cutting edge plays an important role in micromachining,” Läng explains. “You can only run feeds in the micrometer range if the insert is similarly sharp.” Three different tools are used for turning a screw. First, the face of the screw head is axially turned. “We turn the head first because we cannot pick up and clamp the screw on the fine thread,” Knecht says. The smallest screw variant produced at Aeschlimann has a thread diameter of 0.2 mm. After machining the flat surface, the screw head is slotted. Then, the thread diameter is turned by reversing the direction of spindle rotation, after which the thread is milled up to the screw head without an undercut. A Horn tool from the µ-Finish program is used for screw tapping.

Use of microscopes is important because with the naked eye, the workpieces can hardly be distinguished from a piece of fine swarf.

The service life of an insert during reverse turning is approximately 17,000 screws. When parting off, the cutting edge achieves a tool life of 40,000 screws. “With the new Horn coating ES15, we are able to increase productivity even more,” Knecht notes. The new coating is a HiPIMS layer (high-power impulse coating magnetron sputtering). HiPIMS produces an even more homogeneous and significantly more durable coating whose hardness and toughness are especially suitable for steel machining and for machining small and very small parts (see sidebar below).

Horn also uses physical vapor deposition (PVD) technology for its tool coatings. PVD is a process in which the coating material is vaporized by electrons, laser beams or arc discharges. The vaporized material is deposited as a coating on the workpieces, forming a layer. By varying the supply of reactive process gases, the coating composition can be influenced. In this way, nitrides or carbides or mixtures of the two layers are formed during the coating process. PVD coatings increase the service life of cutting tools many times over.

The Value of Partnerships

In Switzerland, Dihawag represents the German tool manufacturer, Horn. The partnership between Aeschlimann, Horn and Dihawag has existed for over 20 years. During this time, Horn has been able to successfully solve a number of machining applications with its tools. “The cooperation is paramount,” Knecht says. “The technical advisors from Dihawag and Horn take care of our machining applications quickly and reliably. There is a real partnership and delivery of the tools is very quick.”

Related Content

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreStarting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)