Source: (top left) The L.S. Starrett Co., (top right) Rösler, (bottom left) Evan Doran, (bottom right) LK Metrology

From the integration of Artificial Intelligence (AI) into machining processes to the intricacies of CNC lathes, our coverage in March delved into a diverse array of topics crucial to the precision machining industry. Whether you're seeking to catch up on what you might have missed or looking to revisit your favorites, this list offers a valuable resource. Explore the latest advancements, strategies, and innovations that are shaping the landscape of precision machining, and stay ahead of the curve:

Source: American Certification Group

Can an artificial intelligence program improve your quality management system (QMS)? If you agree that an effective, documented process should include responsibilities, action steps, as well as be understandable, accessible and accurate, then the answer is yes. Read the full article.

At Cross Manufacturing's Devizes, England production unit, two coordinate measuring machines (CMMs) from LK Metrology, built in 1997 and 2007, recently underwent upgrades. These upgrades included fitting multiwired NMC300 controllers with updated firmware and software, future-proofing the machines. This allows for the use of various sensors, not just touch-trigger probes. Additionally, two new Renishaw PH10MQ motorized probe heads were installed as part of the project. Read the full article.

Metal turning shredders, bundle breakers, rolling-ring crushers and hammer mills and horizontal- and vertical-axis crushers seem to achieve the same basic output. That is, they modify metal scrap to create smaller, flowable chips and reduce overall scrap volume. So, what are the unique benefits and limitations of these individual components? Read the full article.

Source: Modern Machine Shop

Famar Group ensures machine stability by producing bedframes in-house at its Avigliana, Italy factory. This attention extends to components like inverted spindles for lathes, horizontal spindles for machining centers, and multi-machine production lines. Strict standards and control over components result in versatile machines suitable for various applications, benefiting customers. Read the full article.

In the aerospace and medical industries, mass finishing and shot blasting processes are critical for achieving a quality surface finish while ensuring the reliability and safety of critical components. These two distinct technologies used for surface finishing of components each have a unique method and application. Read the full article.

Source: Federal Reserve Economic Data (FRED)

According to a report by Deloitte and the Manufacturing Institute, over the next decade, 4 million manufacturing jobs will likely be needed — and 2.1 million are expected to go unfilled — if we do not inspire more people to pursue modern manufacturing careers. Clearly, the potential for employment exists. Read the full article.

Source: The L.S. Starrett Co.

Do you take surface plates for “granite?” Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs. Read the full list here.

Source: BeatDown Outdoors LLC

When not tending to customers or making parts at Ideal Tool and Manufacturing, Blake Price, the company's vice president, enjoys fishing for bass and crappie on nearby lakes. During one fishing trip with his father, Todd Price, they identified a need for a better mount for their electronic fish finder. They then created a more efficient design and recognized its market potential. Together with their team, they began developing a manufacturing plan. Read the full article.

Various machine shops profiled in Production Machining have created side businesses for various reasons. For some, it was based on satisfying personal interests. For others, it was about creating a complementary business. Take a look at how others have turned their passions into side hustles in this article.

Source: Powill Manufacturing

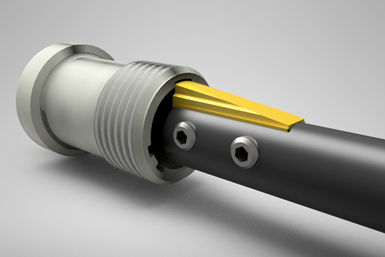

Shops can gain several advantages by using a CNC lathe for broaching. By immobilizing the lathe’s spindle and moving a broaching tool into the workpiece, keyways and slots can be created, allowing for multiple operations in one setup on a single machine. This enhances accuracy between features, cuts down on setup time, and eliminates the necessity for specialized broaching equipment. Powill Manufacturing & Engineering is one shop in particular that finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe. Read the full article.

.jpg;maxWidth=300;quality=90)