Recycling Solves the Problem of Expensive Solvent Maintenance

On-site solvent recycling reduces operational cost, lessens waste disposal, improves cleaning quality, minimizes process interruptions and more.

When Kapture is attached to an existing degreasing unit, the waste is automatically separated from the solvent for required periodic disposal, and the fresh solvent is released to the degreaser in small increments.

Photo credits: Kyzen Corp.

If your manufacturing process includes the use of solvent to degrease your customer’s parts, you are likely aware that proper disposal of hazardous waste generated by a degreasing unit is costly and maintaining an efficient degreasing process requires clean solvent. What you may not know is that in-house solvent recycling provides cost savings while improving solvent quality. With today’s supply chain challenges and price increases, making every drop of solvent count is more important than ever.

As parts are cleaned in a typical degreaser, the contaminants removed by the solvent begin to increase in volume over time. To maintain the solvent purity level within acceptable ranges that do not affect cleaning capabilities, it is necessary to remove the contaminants from the degreaser on a regular basis. Some users will simply replace the bath with new solvent and dispose of the contaminated solvent. However, this practice increases operational costs and interrupts the cleaning process.

An in-house solvent recycling system such as Kyzen Corp.’s Kapture recycling system ensures that parts being cleaned are exposed to a high purity level of solvent, thus improving final part cleanliness levels. Recycling also extends bath life and consolidates the soils, reducing waste volume and operational cost.

How the System Works

As there are numerous benefits to solvent recycling, one of the most critical is maintaining a high solvent purity level. Typical degreaser solvent cook-down without a recycling system generally occurs at 12% soil loading, which is approximately every 4 to 6 weeks based on solvent volume. However, using the recycling unit automatically removes soils from the boil chamber in the degreaser on a continuous basis during operation hours, creating a consistent solvent purity level. By implementing Kapture on a degreasing unit, the waste is automatically separated from the solvent for required periodic disposal, and the fresh solvent is released to the degreaser in small increments.

The recycling system requires no maintenance until the waste storage container located inside the recycling cabinet has reached the preset capacity (approximately 80% full). Until the capacity is reached, however, the system condenses the waste volume to conserve solvent and reduce the disposal stream.

Kapture consists of all components mounted in a cabinet that can be easily moved to the proper position. It can be connected to most degreasers with a line from the recycling unit’s transfer pump and a gravity return

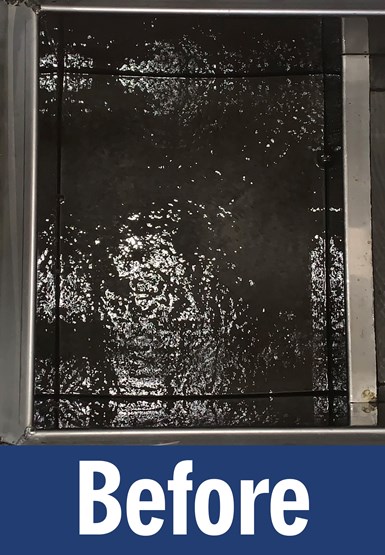

These before and after photos illustrate the effects of the Kapture recycling system 24 hours after implementation.

line for the recycled clean solvent for reuse. A 120 volt alternating current (VAC) at 15 amps and a compressed air supply are needed, but no water is required.

Reclaiming Solvent Makes Sense

Recycling solvent, whether on a continuous basis or a random batch-type operation, offers other benefits as well. First, contaminants from the solvent bath are removed, which increases bath life, decreases the frequency of solvent replacement and reduces the amount of solvent that is normally sent out as hazardous waste.

Recycling also reduces the overall solvent usage/cost on a yearly basis. The amount of good, reusable solvent that would normally be entrained in the contaminated solvent bath when replaced in a typical vapor degreaser without a recycling system may be as high as 50 to 75% by volume. Companies can lower this entrained amount to expected levels of 5% or less by reclaiming the solvent.

Also, by using on-site recycling, a machine shop can reduce the environmental assessment of the degreasing system by solvent conservation. The user’s air permit for the degreaser system is typically limited to a gross amount of solvent usage stated in pounds or tons per year. Less solvent shipped out as a waste product equates to less solvent assessed toward the permitted limit and fewer dollars spent for disposal.

About the Author

Joe McChesney

Joe McChesney is the global products line manager – solvents at Kyzen Corp. He has 40 years of experience regarding solvent and aqueous cleaning processes from conceptual design through field operation. He holds several patents on solvent applications. Contact: joe_mcchesney@kyzen.com, 270-202-1413

Related Content

Multisolvent 100 Vacuum Vapor Degreaser Provides Contactless Cleaning

PMTS 2023: With applications in the most demanding industrial sectors, the machine is especially useful for cleaning parts in the turning, precision mechanics, medical and aerospace industries.

Read MoreIn-line Monitoring for Automated Immersion Cleaning Systems

Ecoclean’s Acoustic Performance Measurement (APM) system provides in-line measurement of ultrasonic frequency and power in fully automated immersion cleaning systems on a batch-by-batch basis or at defined time intervals, such as once a shift, day or week.

Read MorePMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Read MoreSita’s CleanoSpector Measures Part Cleanliness

PMTS 2023: Handheld measuring device checks for cleanliness of parts to assure product quality as well as prior to follow-up processes.

Read MoreRead Next

Vacuum Degreasing Offers Lean and Green Technology

One common cleaning system will work on all production parts without having to operate and maintain separate systems.

Read MoreThe Right Solvent Creates the Cleanest Parts

Cox Manufacturing Co. has worked with Kyzen Corp. since it implemented its vacuum vapor degreaser to find just the right chemical solvent to clean its customers’ parts to their specifications and beyond.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More