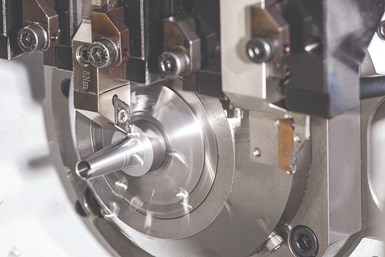

This quick-change tooling system for Swiss-type lathes is said to provide the rigidity of a solid tool to help ensure long tool life. (Photo Credits: Iscar)

Modular, quick-change tooling systems for Swiss-types consist of shanks that remain installed in a machine and insert heads designed for easy removal/reinstallation. This can reduce downtime when there are frequent setups because job batch sizes are small, while enabling redundant insert heads to be staged near a machine for long-running jobs.

Iscar has recently taken a closer look at how insert heads are clamped to shanks. Clay East, the company’s national product manager for turning products, says shops have cited high overall rigidity and insert head positioning repeatability as the two prime features they look for in such tooling systems.

This led Iscar to develop its NeoSwiss line of quick-change tooling for Swiss-type lathes which has been offered since mid-2022. What’s unique about this tooling system is the proprietary rotary wedge clamping system. East says the high clamping forces this design achieves creates a highly stable interface between the insert head and shank such that a two-piece NeoSwiss offers the same rigidity and tool life as a solid tool. Plus, insert head positioning repeatability is ±0.0008 inch.

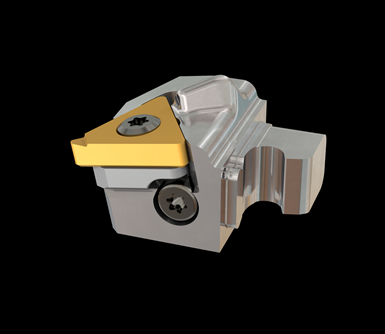

The rotary wedge mechanism is designed to amplify the clamping force and simplify head replacement.

A variety of heads are available for multiple machining operations, including turning, backturning, threading, grooving and parting. In addition, X-axis and Y-axis heads can be used on the same shank. East says Y-axis turning or grooving can be an option for shops experiencing stability issues or chatter when performing those operations in the X axis or if long chips are an issue because Y-axis machining directs them down and away from the workpiece.

“Shops told us they required rigidity and repeatability in quick-change, Swiss-type tooling.” Clay East

The NeoSwiss system accepts a wide range of insert heads and insert designs. X- and Y-axis heads can be used on the same shank.

All NeoSwiss shanks and heads are produced with Iscar’s JetCut coolant-through capabilities and can be used with coolant pressures as high as 2,000 psi. The majority of NeoSwiss heads come with two different coolant ports — one exiting above the insert and another below it — to reduce the heat in the cutting zone, improve insert life, and assist with chip breakage, control and evacuation. The internal coolant ports, which are designed via computational fluid dynamics and created via 3D printing, also eliminate the possibility of chips catching on traditional external coolant nozzles.

NeoSwiss shanks are currently available in 0.5 inch, 12 mm and 16 mm sizes, although 10 mm and 0.375 inch sizes will soon be offered.

Related Content

-

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

-

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

.png;maxWidth=300;quality=90)