So, You Need To Automate Your Multispindle...

You can't decide if you need an integrated loader or a stock reel loader. You've boiled it down to a space versus cost decision. Now what do you do? You basically have two choices: the stock reel loader or an integrated loader.

You've thought for a long time that you need more production from your multi-spindle lathes. And you know that automating the barloading process could increase your productivity by up to 20 percent. That does not even take into account the ergonomic and safety issues of manually loading bars. Yet, you can't decide if you need an integrated loader or a stock reel loader. You've boiled it down to a space versus cost decision. Now what do you do? You basically have two choices: the stock reel loader or an integrated loader.

A typical stock reel loader is available in 2.5-ton bundle or multi-layer rack configurations. Both would be appropriate additions to the existing OEM equipment. This type of loader automates the stock reel loading sequence and allows the lathe to continue to operate normally during the feed cycle. Stock reel loaders will feed both six- and eight-spindle applications and handle bars up to 4 inches in diameter.

The integrated style of bar feeders for multi-spindle lathes would replace the existing OEM stock reel and feed system. Available for both six- and eight- spindle lathes, the integrated loader automates the process even further. During the feeding cycle, the integrated loader's hydraulic feed system pushes the bar stock through the collet to the proper part length maintained by the standard multi-spindle stock stop. The oil bath bar support yields a quieter operation. Multi-layer rack and 2.5 ton bundle versions are available. Both may help automate a shop to run "lights out" where it was previously impossible.

Adam Hoeker of P.H. Precision (Suncook, New Hampshire) decided to go with stock reel loaders from a price/serviceability perspective. "Inexpensive yet reliable automation: that's what we looked for. It takes up a bit more floor space, but even if the stock reel loader goes down, you can still hand load the bars and continue with production while you work on fixing the loader. When an integrated bar feeder goes down, it takes you out of production until the bar feeder is fixed."

In this case, cost won out over the space issue. Secondary to the initial cost is serviceability and flexibility. Although stock reel loaders have proven to be extremely durable and reliable, the operator does have the option of manually loading the multi-spindle if the need arises.

Stephen Wing of Greystone Manufacturing found himself in somewhat of an unusual situation when he was deciding to automate his feeding process. At one of his facilities, floor space was not an issue, and he decided to purchase stock reel loaders because they offered an inexpensive way to automate. Stock reel loaders are typically 60 percent of the initial cost of an integrated loader.

However, Mr. Wing did not have to sacrifice features for price. Stock reel loaders offer a wider range of applications including the ability to work with larger diameter bar stock and to retrofit to older lathes. Also, stock reel loaders have fewer moving parts, requiring less maintenance.

Conversely, at his Rhode Island facility, an ever-tightening floor space issue was the driving factor behind his decision to go with an integrated loader. The integrated loader also offers a few other advantages besides saving floor space. It replaces the manually loaded OEM feed system allowing the elimination of the feed tubes and feed fingers, offering a more reliable feed and potentially increasing diameter capacity of the screw machine. An oil bath around the rotating bar contributes to a quieter work environment.

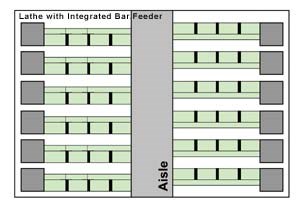

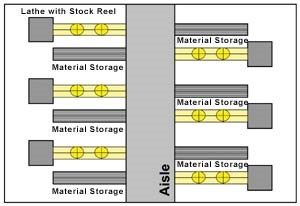

Here are some typical floor plans for arrangement of bar fed multis.

That's the long and the short of it. If you're sold on automating the barloading of your multi-spindle; now it's simply a matter of choosing the right option for your shop. Space versus cost. Take the time to lay out your shop to see which scenario will be best for your operation.

— Bucci Industries USA

Related Content

Accessory Speeds Centering Align Drills on CNC Multi-Spindles

The CenterMaster accessory is designed to streamline the setup and changeover process for CNC multi-spindle lathes.

Read MoreMethods Multitasking Machine Reduces Cycle Times

Methods Machine Tools Inc. introduces Nakamura-Tome’s WY-100V two-turret, twin-spindle precision CNC multitasking lathe to the U.S. market.

Read MoreIndex Corp. Turnkey Solutions Provide Flexible Manufacturing Performance

IMTS 2024: Index's C200 FANUC features powerful twin spindles that achieve rapid material removal.

Read MoreSoftware Controls Chip Breaking in Thread Turning Operations

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)