Sometimes It’s the Steel

Sometimes it can be the steel. Frustratingly, because it came in exactly as you asked. Ask better.

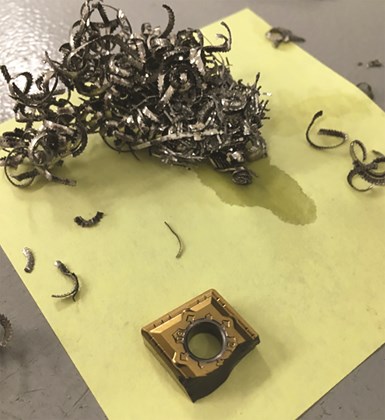

Photo courtesy of Ryan Kutz

I have been working in the steel and manufacturing industry for 49 years. I started out as a laborer in the blast furnace department right out of high school and I worked in the steel mills full time as I went to college full time. I might or might not have been full time distracted by other things in those college days as well.

As my career developed, I increasingly became more involved with customer service and problem-solving, where the first claim to be made by our customers was that “It must be the steel. There are hard spots in it.” (Actually, there were none to be found.)

“It must be the steel, it only cracks at this one place on our part.” (And just how is it that we know how to put a flaw at exactly that one place on every length of steel in that exact spot for each part in the miles and miles of steel that we made of that size and grade? And then gave it only to you?)

“Your steel is burning up our tools on this one machine. It must be the steel.” (But that same steel is running successfully on four other machines and across three shifts, but it is only failing on this one machine and destroying tools only on this one shift? Hmmm, let me think about that.)

“Your steel changed over the weekend and now we can’t get it to hold size.” (The experienced operator went on vacation and his replacement hadn’t even been confirmed to use micrometers with a Gage R&R.)

Handling these types of complaints was not that difficult — there is a certain logic that fails in the complaint and, besides, I had complete confidence in the steel. I not only knew every step of the processes that made it, but I had also supervised the lab testing and reporting.

But, occasionally, we would encounter a claim where there was clearly a difference in performance of steels that were by all accounts of equal quality and provision, but somehow there was a difference that impacted its processability.

Know the Supplier

My first involvement with one of these was as a cold finisher. We could buy the hot roll steel we needed for cold drawing from a major integrated mill like US Steel Lorain or Inland Steel. These mills had Basic Oxygen Furnace (BOF) melt shops and, at the time, were ingot casting. At the time it was called “hot melt,” as hot molten blast furnace iron was the basis for the steelmaking charge.

The other option that we had was to buy the hot roll steel from one of the new minimill operations that were springing up around the country. These shops just re-melted scrap, so the steel had higher residuals and, because it wasn’t BOF, it ran higher in nitrogen. (In the BOF process, all atmospheric nitrogen is displaced by all of the oxygen blown into the vessel). This scrap-fed electric furnace continuous caster steel was called “cold melt.”

Can you see where this is going? In an effort to save costs, the buyer asked us to give him half a truckload of the “good stuff” (hot melt) and fill the rest of the truck with the cold melt. The savings between the two would look great on his bottom line.

The job was the swivel shaft used in office chairs that had a section which was created with a form tool and then a very heavy square-formed thread. They set the machine up using the hot melt and everybody was happy. Then they set up the second machine — using the same feed speed depth of cut — to make the identical part using the cold melt. Couldn’t get a part in two shifts of trying. Clearly, there was a difference in the steel. BUT THE STEEL MET EVERY ORDER REQUIREMENT FOR CHEMISTRY, DIMENSION AND PROCESS. Both materials came from my company, my plant, had my blue bands and clips packaging, and were certified to ASTM A 29, A108, and to chemistry. Both were exactly what was ordered.

But there was a difference in the ultimate sourcing and process that produced the steel itself. Sourcing and processing differences REALLY MATTER!

Getting What You Asked For

Recently, a PMPA member asked me to look at two certs for the same grade of steel. The sizes of the items purchased were different, but otherwise they were ordered to the same grade and spec. They came from the same service center, who bought them from the same cold finisher. The member didn’t tell me which steel was “good” and which was “bad,” just two certs. It was pretty easy to figure out which was the “bad” steel when looking at the test reports, even though the chemistries were virtually identical.

The cold finisher had sourced the two batches from different melt shops, and the hardness mechanical testing results from one of the heats and other cert information from both heats made it pretty easy to figure out that one item had in fact been cold drawn. The other had been “cold finished” — i.e., turned and polished, leaving it in a gummy state as no cold work had been done to the steel.

Both items were compliant with the requirements to which they were ordered, but one item was cold finished, not cold drawn. There were some other factors that also contributed to issues that I won’t get into here. In the end, yes it can be the steel. But, as both of these cases show, that problematic steel was provided EXACTLY HOW YOU ASKED FOR IT AND ACCEPTED IT.

The Bottom Line

You need to be quite specific about what you expect the steel that you machine to be.

Cold finished can mean cold drawn, cold-drawn turned and polished, turned and polished, or various other special finishes. Cold drawing adds mechanical properties that help make the chip ‘crisper’ and easier to make. A single supplier to you could have multiple suppliers to them for the same grade and size.

Be specific on what you order and just as careful on reviewing certs and test reports. Because, yes, once in a while, it can be the steel, and that steel was provided “Just as you asked for it to be.” Ask better.

Read More Articles from PMPA:

About the Author

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email: mfree@pmpa.org; website: pmpa.org.

Related Content

A No/Low-Cost Solution to Employee Retention

Studies show a little employee recognition goes a long way. Here are the 5Ws to consider for success.

Read MoreKeeping It In The Family — Succession Tips From Those Who Lived It | Part 1

PMPA members share some tips to avoid getting burned when passing the business torch from one family member to another.

Read MoreCraftsman Cribsheet No. 121: ISO Turning — What Does it All Mean?

How to make sense of all those different letters and numbers in ISO turning inserts.

Read More‘Can You Hold This Tolerance?’ Is Not An Engineering Question

The implications of tolerances go far beyond mere technical compliance.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)