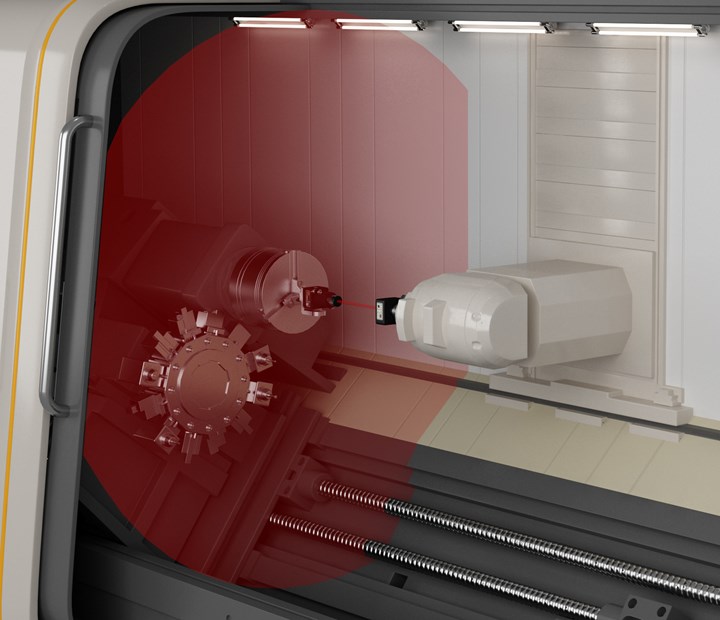

Hamar Laser has developed what is said to be a fast and highly accurate process using its T-1296 5-axis laser target combined with the company’s L-702SP spindle alignment system to align machine tool spindles and axes. Photo Credits: Hamar Laser Instruments Inc.

In the battle against downtime and added costs, preventive maintenance is a machine shop’s friend. Ensuring machine tool alignment for all shopfloor equipment is a periodic maintenance check that should not be ignored. This critical process can prevent machine tool failures and problems that can lead to expensive repairs and extensive downtime.

On a lathe, for instance, the headstock spindle axis is frequently knocked out of alignment of the guideways due to crashes or wear and tear. This parallelism error results in tapered parts and other quality problems, increasing scrap rates, machine downtime and costs. Being proactive with periodic machine geometry checks helps to identify alignment problems before they turn into part problems and is critical for maintaining good machining accuracy and increasing throughput.

To that end, Rod Hamar, president at Hamar Laser Instruments Inc., says his company has developed a fast and highly accurate process using its T-1296 5-axis laser target combined with the company’s L-702SP spindle alignment system to align machine tool spindles and axes.

Lasers from the Beginning

Hamar Laser opened in 1967 as a result of frustration felt by its founder, Martin Hamar. Martin’s son, Rod Hamar explains that Martin was employed by a company that was great at engineering lasers, but not very adept at making the equipment user-friendly so the customer could actually use the equipment. “This company expected their customers to develop a way to display the data themselves. That’s expert friendly to say the least,” Rod Hamar says.

After working there for a year or so, Martin grew weary of explaining to the customer all the work they had to do to use the system they bought and thus began his own business, Hamar Laser Instruments Inc.

Hamar Laser’s spindle alignment equipment, according to Rod Hamar, is faster, more accurate and more efficient than using traditional alignment equipment, including test bar indicators and laser interferometer/laser trackers.

One of the company’s earliest applications was aligning machine tools, and it has spent decades developing and refining these systems for the machine tool industry, including those for lathes, multitasking machines, machining centers and ID/OD grinding equipment.

Measuring for Straightness, Flatness, Squareness and Parallelism

With a 10- to 15-minute laser setup to the spindle rotation axis, Hamar Laser’s alignment equipment can measure the straightness, flatness, squareness and parallelism of the lathe and machining center axes. The process begins with inserting a laser in one spindle and a measuring target in the spindle facing it. The laser is then aligned to the rotation axis of the main spindle. From there, the target can be moved to measure the various axis lines of motion, as well as subspindle rotation axes for alignment relative to the main spindle axis.

The new target is part of an alignment kit that includes Windows software and communicates with the laptop via a Bluetooth link. The process starts with setting up a machine tool project in the company’s MultiTurn10 software, where the operator selects which axes to measure, the number of points, the distance between the points, the tolerances and laser setup. Next, the operator chooses which axis to use as a reference for the laser, which on a mill-turn machine is typically either the main spindle rotation axis or the Y or X machining axes. With on-screen procedures, the software also helps guide the operator through the setup process to align the laser to the machine reference.

After the setup process is complete, the multitasking machine’s Z-axis straightness data can be recorded in the software, as well as the W axis and C2 subspindle axis, all from the same setup. A second setup is then needed to record the final data for the X and Y axes. In addition to straightness/squareness, pitch and yaw axis measurements can be recorded by adding a high-resolution lens to the T-1296.

This screenshot of the system’s software shows what the screen users see when recording axis straightness data. Although spindle alignment equipment is used preferably for preventive maintenance, it is also helpful for troubleshooting in cases where there has been a machine crash. Rod Hamar explains that a quick spindle alignment check takes only 10 to 15 minutes to help an operator decide if the machine needs to be taken offline after a crash. “You don’t have to do an exhaustive check of the machine to see if the head is knocked out. With real-time data updating, you can do quick spot alignment checks and not take extra time having to measure the whole axis.”

Once all the data is recorded, the operator clicks on “Results,” and the software analyzes the data. From the data, the operator can adjust the axes and spindles to align them, using the software analysis as a guide. The software shows the operator in real time the results of the adjustment.

Targeting the Highest Resolution, Wirelessly

The T-1296 5-axis target is a high-resolution version of the company’s T-1295 5-axis multipurpose target designed to work with the L-702SP spindle/machine tool alignment system. The T-1296 features a position sensing detector with a resolution of 0.00001 inch (0.00025 mm) for center alignment and 0.00004 inch/ft. (0.003 mm/m) for pitch and yaw angular checks. It has a 0.5-inch (12.7-mm) mounting stud to insert into a spindle collet or chuck. The target is powered by a rechargeable battery with 10 or more hours of battery life. The T-1296 is also designed to work with the company’s beam lasers to measure center and angular alignment values as well as with its scanning lasers to measure flatness and squareness, reducing the number of targets needed for the kit.

The idea for creating the T-1295/1296 5-axis targets stemmed from the desire for a wireless version of the company’s 4-axis spindle target to connect to the software, eliminating a computer interface and reducing cost. Hamar says the company used an existing wireless target for shaft alignment as a base to develop and repackage the wireless electronics into the new target for the spindle and axis alignment applications.

The T-1296’s five measurement axes are vertical, horizontal center checks, pitch and yaw angular checks, and an extra axis used with the scanning (plane). The plane laser is created by shooting the laser beam through a spindle with a pentaprism mounted on top, which turns the beam 90 degrees, and then continuously turns the spindle to sweep the laser plane. This enables not only more alignment checks with a given setup than a typical beam laser but it can also measure twist/roll easily on machine tool guideways as well as squareness and parallelism.

Hamar Laser Instruments Inc. | hamarlaser.com

Read Next

Optimize Spindle Performance by Analyzing Failure

An in-depth failure analysis report documents findings and includes recommendations for corrective actions.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)