Technical Member Profile: Henning Industrial Software

In the early days, the Hennings’ customers were primarily small- to medium-sized precision machining companies.

Henning Industrial Software Inc. was founded in January 1990 by Billie J. and Richard G. Henning. Prior to that, Mrs. Henning had been working at a family-owned, precision machining shop while her husband was employed by the Cleveland Clinic Foundation as a software engineer and systems analyst.

In his spare time, Mr. Henning had also been writing job estimating and job costing programs for the metalworking company where his wife worked. The couple looked into purchasing software for that company, but could not find what they needed. "The software available at that time wasn’t worth the money," says Mrs. Henning, vice president of Henning Industrial Software. "We decided to develop our own software and then market it to the machining industry."

Mrs. Henning left her full-time machine shop job and started calling on potential customers. "At that time, the first question I asked was, ‘Do you have a computer?’ Only one out of ten companies I called on owned a computer back then. I had to convince those without computers to buy one before they could use our software."

In the early days, the Hennings’ customers were primarily small- to medium-sized precision machining companies. "Metal turning was my background, so that was the primary market we initially served," Mrs. Henning explains. "Eventually, other types of manufacturing companies came to us looking for help. Today, our customers can be any type of manufacturing operation."

In 1994, Mr. Henning left his job at the Cleveland Clinic Foundation to work full-time at the couple’s software company. The staff has since grown to 14 employees at the Hudson, Ohio, headquarters and Henning Industrial Software now serves more than 900 customers.

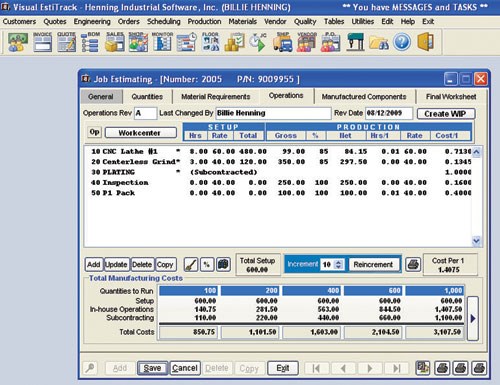

"Our product is Enterprise Resource Planning (ERP) software for shop management," says Mrs. Henning. "It does everything from estimating, order tracking and scheduling to quality control, inventory and costing. Everything is tied together." The software products are marketed under the brand names Visual EstiTrack and Visual Books.

Henning Industrial Software has been a PMPA member since 1998. "I actually got involved with PMPA in 1995 when the association hosted a software-only trade show," recalls Mrs. Henning. She has served on the PMPA Information Technology (IT) Committee for the past eight years, including a stint as chairperson. She is also one of the founding members of the Precision Machining Technology Show (PMTS) Committee.

"The IT Committee is all about what’s new in information technology and how PMPA members can benefit," Mrs. Henning continues. "We look at things like new operating systems, barcoding and radio frequency identification (RFID). It depends on what’s going on in the industry at that time."

Mrs. Henning and others from her company attend most of the national PMPA meetings. "Because of my involvement on the IT Committee, we usually make presentations at many of the conferences," she states.

In addition to the Hudson headquarters, Henning Industrial Software has a satellite office in Toledo, Ohio. Gayle Bayer, who works at that office, serves on the IT and Quality committees and is an officer for the PMPA’s Southeast Michigan chapter.

"The PMPA is a great association," says Mrs. Henning. "They have great people, great organizing skills, and they give us a lot of useful business information."

Mrs. Henning praises the networking opportunities at the national meetings and conferences. "I go to a meeting like Management Update and see many of my customers all at once," she says. "Where else could I do that?

"PMPA is not just about getting new customers, but about seeing and maintaining relationships with the customers we already have," Mrs. Henning emphasizes. "That is wonderful. We don’t go to the meetings to sell. Our purpose is to help PMPA and to teach PMPA members about the benefits of shop management software. We show them how it can help their businesses grow."

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)