It pays to be a winner. This mindset is especially true for military professionals who go through rigorous training, desiring to contribute to a winning team. “More value accrues to those who are contributing to success,” says Bill Berrien, CEO of Pindel Global Precision Inc. in New Berlin, Wisconsin. Serving almost nine years in the Navy SEAL Teams special operations community, Berrien believes the military is “the best” at professional development and continual upskilling throughout one’s career.

He applies upskilling principles learned in the military to train his advanced manufacturing team members. By implementing Pindel’s Professional Development Program, employees who successfully learn more advanced skills move up the pay scale. As a result, the company does not depend on hiring skilled workers, but instead, hiring people with positive attitudes and an eagerness to learn. Berrien calls this philosophy “hire for attitude, train for skill.”

Military Parallels

Following his service as a SEAL which included working with all branches of service, Berrien has been part of the advanced manufacturing community for 11 years. During that time, he has assessed the parallels between the production machining industry and the military’s special operations. He explains that both are about small, highly trained, highly cohesive teams, enabled by advanced technology, striving to accomplish outsized objectives to “punch above their weight.”

Berrien uses a CNC Swiss machinist’s role as an example. “It’s amazing what a CNC Swiss machinist can do in terms of scaling, augmenting their output across a number of Swiss machines, all running complex parts,” he says.

However, as he realized this similarity, it also became evident to him that upskilling and professional development of which the military has demonstrated the value, was lacking in the advanced manufacturing industry.

According to Berrien, the industry is not serving workers well over the age of 25, especially at small- to medium-size companies. While the younger-than-25-year-old employees are more willing and able to go to full-time school to learn the trade, the older employees are not well positioned to do that. That fact necessitates in-house training,

Upskilling is a talent development technique that benefits the industry and the employee. Photo Credit: Getty Images

which is not always optimal. Also, often the limited industrywide standards of training and skill sets learned are not transferrable if individuals become employed by another company.

Therefore, creating programs like upskilling to bring talent up through an organization aids employees in establishing a profession. Upskilling, simply put, increases the skills an individual already has.

Professional Development Program

With the focus to generate value for employees, years ago Pindel developed a training program for all skill levels covering production, quality and industrial maintenance positions. Online classes and credentials as well as OEM training have been woven into the program to offer continual progressively challenging learning opportunities.

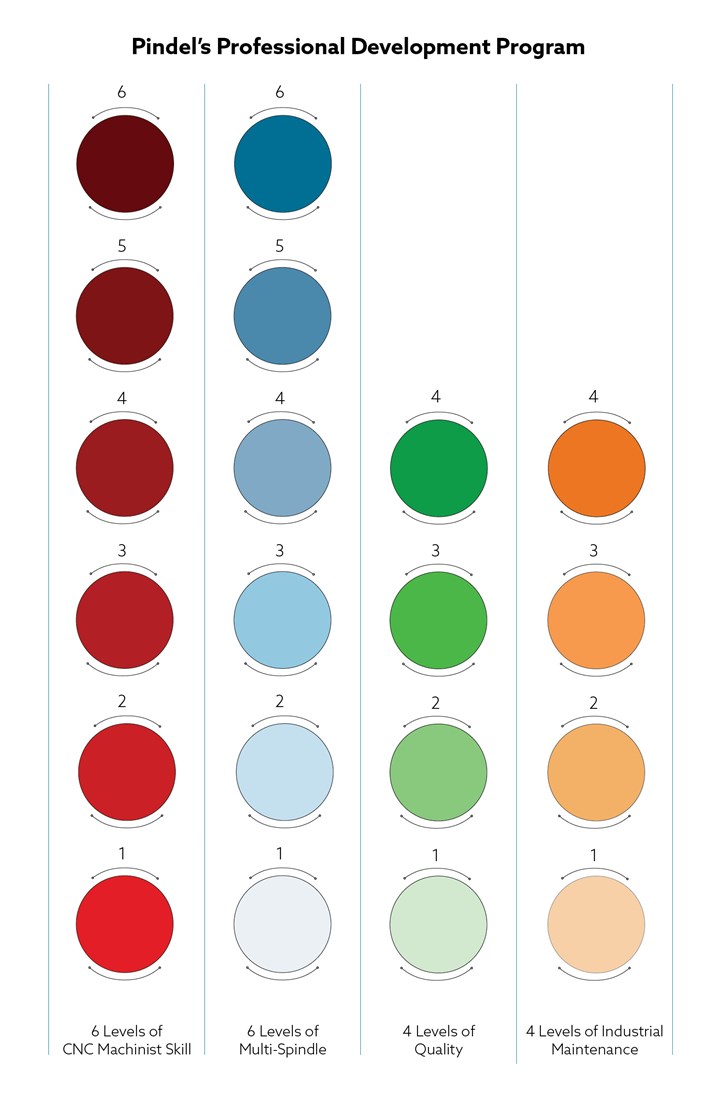

Pindel’s Professional Development Program consists of six levels of CNC machinist skill, six levels of multi-spindle, four levels of quality and four levels of industrial maintenance. Each level includes ToolingU online classes that have been curated and are particularly specific to that level of capability and rigorous shopfloor qualifications. National Institute for Metalworking Skills (NIMS) credentialing is also worked into these levels. Each level also has wage bands that increase pay for employees moving up the ladder.

Berrien stresses the importance of industry-relevant training with credentials due to their portability. Employees earning national credentials make their skillset transferrable to other companies and geographies, he says.

He adds that supplementing the NIMS credentials with OEM training is another way to provide even more value to an employee through the upskilling process. Taking advantage of sometimes free training by OEMs that will visit a facility for on-site classes is an easy way to upskill.

“We’ve sent seven of our machinists to Hexagon Esprit CAM training,” Berrien says. “They might not be programming all the time, and that’s OK. But it is something we will be asking them to do on occasion, and we consider programming one avenue on a machinist’s path to professional development.”

Pindel provides its employees with the tools necessary for continual learning, including a laptop and remote access so they can do training at home if that is ideal for them.

Moving ‘Up’ the Levels

When an employee is enrolled in Pindel’s upskilling program, that individual usually goes through all the levels of the Professional Development Program, whether they are experienced and skilled or not. He or she might already know most of the material, but in the process, that person learns something. However, the ToolingU assessment online will place the employee in the correct class module for his or her skill level.

To understand more about the upskilling program at Pindel, Berrien steps through an example of an employee in one of the shop’s machining areas who is inexperienced. The company introduces the upskilling program to this individual by opening the ToolingU online classes for him/her and other employees. They go through the material, including videos, tests, retaking tests if needed, reading and so on. That is complemented with appropriate shopfloor qualifications to match their level of skill and capability.

Then, all their training and qualifications are captured in the shop’s ERP system where they can advance to higher levels within that professional development program and enter a higher wage band.

Employees earning national credentials make their skill set transferrable to other companies and geographies.

However, advancing to a higher level of capabilities is not the only way to receive more pay, Berrien explains. “There is also the opportunity within that wage band for higher value added within that skill set.” So running additional parts, good production and quality, and leadership can be other factors and development paths contributing to higher pay.

Start by Keeping It Simple

For a company that would like to upskill its employees who have not yet taken steps to do so, Berrien suggests first defining which skills would add the most value to the shop. Calling a brainstorming session with a group of experienced shopfloor leaders can be a productive way to determine the most critical skills needed for the organization.

Stating that it is not necessary to put a lot of structure to the upskilling process, at least at first. Berrien sees the basic framework of an upskilling program as a 2-by-2 matrix. The two axes of the matrix, he says, are the level of impact of the skills and difficulty or cost of providing those skills.

After defining these axes on the matrix, the business should prioritize the efforts by highest impact, lowest cost, he explains.

Pindel Global Precision’s core business is high complexity, close tolerance precision machined parts and assemblies.The company is equipped to serve customers that need a high volume of precision machined parts in a short amount of time. Photo Credit: Pindel Global Precision

Next, he says write those skills on a whiteboard and choose who can teach those skills. Is it someone in-house or is outside training necessary? Then, move on to the next item, which will be slightly lower impact, but still inexpensive. Berrien recommends first focusing only on the skills that are high impact and inexpensive.

Implementing ToolingU, which offers a vast catalog of courses at a low subscription price, is an example of a high-impact, low-cost solution for upskilling. Many free or low-cost training classes are offered by OEMS as well.

While creating an upskilling program does not have to be expensive, there is local and state funding that is available for training expenses, if needed. Berrien notes that Pindel has used federal grant money to fund its upskilling program through Forward Careers (a nonprofit job training organization in Wisconsin) and the Workforce Opportunity Investment Act, which companies can apply for at a local or state level.

“You apply to highlight the training you want to do, and you make a grant request for a certain portion of that training to be partially paid by these funds in return for raising the participants’ wages a guaranteed amount afterward,” he explains.

Hire for Attitude, Train for Skill

Because the company executes its upskilling process, Berrien does not worry about hiring skilled workers. Instead, the shop has the freedom to hire people based on their personality and positive attitude — those who are willing and excited to learn the trade or advance in the trade. Photo Credit: Getty Images

Therefore, the company is not growing based solely on acquiring already skilled talent. Its ongoing upskilling program relieves the shop of relying on recruiting.

Case in point: Berrien describes an example of an employee he hired to be a material handler a few years ago. The organization upskilled him to become a Swiss machinist, and now that person is a key contributor to Pindel’s lights-out reset program. This program requires machinists to come to the shop on the weekends to reset machines that are running lights out. However, those machinists are rewarded for their weekend work time with minimum hours of pay each reset.

“Although it only takes a short while to reset the machines and material and do whatever is needed on those machines,” Berrien explains, “there’s a significant hourly minimum that team members are paid for doing that.”

Pindel Global Precision Inc. | pindel.com

Read Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More